Formaldehyde absorbing material and preparation method thereof

A formaldehyde absorption and absorption material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of reducing formaldehyde concentration and low absorption efficiency, and achieve the effect of strong formaldehyde removal ability and environmental protection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

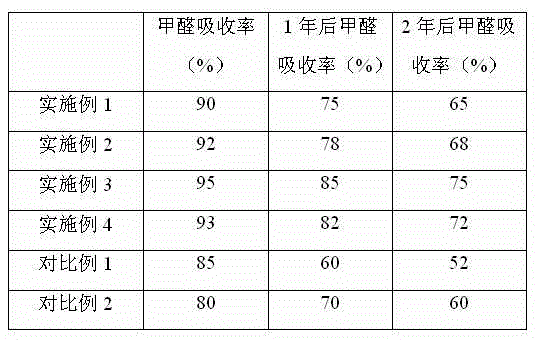

Examples

Embodiment 1

[0026] A formaldehyde absorbing material, comprising the following raw materials in parts by weight: 1 part of glycerin, 0.2 parts of defoamer, 8 parts of ferric ammonium sulfate, 3 parts of silicon dioxide, 15 parts of 200-mesh ceramic powder, and 35 parts of deionized water , 1-4 parts of phenyl o-hydroxybenzoate.

[0027] The preparation method of the above-mentioned absorbent material capable of absorbing formaldehyde comprises the following steps:

[0028] Step 1, weighing raw materials according to parts by weight, mixing ferric ammonium sulfate, silicon dioxide, ceramic powder, deionized water and ultraviolet absorber, and stirring at 10000rpm for 2 minutes to obtain mixture I;

[0029] Step 2, add humectant to mixture I, stir at 200 rpm and heat to 40°C, keep warm for 1 minute, then add defoamer, continue stirring to obtain mixture II;

[0030] In step 3, the mixture II is put into a twin-screw extruder, and the screw speed is 50 rpm to extrude the particle adsorption...

Embodiment 2

[0033] A formaldehyde absorbing material, comprising the following raw materials in parts by weight: 1 part of sodium lactate, 0.2 parts of defoamer, 10 parts of ferric ammonium sulfate, 5 parts of silicon dioxide, 18 parts of 300-mesh ceramic powder, 40 parts of deionized water , 2-3 parts of phenyl o-hydroxybenzoate.

[0034] The preparation method of the above-mentioned absorbent material capable of absorbing formaldehyde comprises the following steps:

[0035] Step 1, weighing raw materials according to parts by weight, mixing ferric ammonium sulfate, silicon dioxide, ceramic powder, deionized water and ultraviolet absorber, and stirring at 11000rpm for 3 minutes to obtain mixture I;

[0036] Step 2, add humectant to mixture I, stir at 250 rpm and heat to 43°C, keep warm for 2 minutes, then add defoamer, continue stirring to obtain mixture II;

[0037] In step 3, the mixture II is put into a twin-screw extruder, and the screw speed is 53 rpm to extrude the particle adsorp...

Embodiment 3

[0040] A formaldehyde absorbing material, comprising the following raw materials in parts by weight: 1-4 parts of sodium lactate, 0.2-0.8 parts of defoamer, 10-12 parts of ferric ammonium sulfate, 5-7 parts of silicon dioxide, and 400-mesh ceramic powder 18-22 parts, 40-42 parts of deionized water, 2-3 parts of phenyl o-hydroxybenzoate.

[0041] The preparation method of the above-mentioned absorbent material capable of absorbing formaldehyde comprises the following steps:

[0042] Step 1, weighing raw materials according to parts by weight, mixing ferric ammonium sulfate, silicon dioxide, ceramic powder, deionized water and ultraviolet absorber, and stirring at 11800 rpm for 5 minutes to obtain mixture I;

[0043] Step 2, add humectant to mixture I, stir at 300 rpm and heat to 48°C, keep warm for 3 minutes, then add defoamer, continue stirring to obtain mixture II;

[0044] In step 3, the mixture II is put into a twin-screw extruder, and the screw speed is 58 rpm to extrude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com