Formaldehyde absorbing material and preparing method thereof

A formaldehyde absorption and absorbent technology, applied in the field of environmental protection, can solve the problems of reducing formaldehyde concentration and low absorption efficiency, and achieve the effect of strong formaldehyde removal ability and environmentally friendly materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

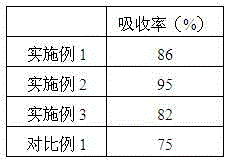

Examples

Embodiment 1

[0020] A formaldehyde absorbing material, comprising the following raw materials in parts by weight: 1 part of glycerin, 0.2 parts of antioxidant, 8 parts of polyphenylene amide, 3 parts of silicon dioxide, 15 parts of 200 mesh plastic powder, 35 parts of deionized water , 1 part of phenyl phthalate, 1-5 parts of carbon fiber, 2 parts of preservative, 12 parts of glass fiber.

[0021] The preparation method of the adsorption material capable of absorbing formaldehyde comprises the following steps:

[0022] Step 1, mix poly(phenylacrylamide), silicon dioxide, plastic powder, carbon fiber and glass fiber, place in a reaction kettle, and heat at 1000°C for 10 minutes to obtain the first mixture;

[0023] Step 2, adding glycerin, antioxidants, deionized water, ultraviolet absorbers, and preservatives to the first mixture, stirring at 200 rpm, and ultrasonically treating at 120 MHz for 12 minutes to obtain the second mixture;

[0024] Step 3, put the second mixture into a twin-scr...

Embodiment 2

[0026] A formaldehyde absorbing material, comprising the following raw materials in parts by weight: 3 parts of glycerin, 0.6 parts of antioxidant, 12 parts of polystyrene amide, 7 parts of silicon dioxide, 20 parts of 400 mesh plastic powder, 40 parts of deionized water , 3 parts of phenyl phthalate, 4 parts of carbon fiber, 4 parts of preservative, and 18 parts of glass fiber.

[0027] The preparation method of the adsorption material capable of absorbing formaldehyde comprises the following steps:

[0028] Step 1, mix poly(phenylacrylamide), silicon dioxide, plastic powder, carbon fiber and glass fiber, place in a reaction kettle, and heat at 1100°C for 14 minutes to obtain the first mixture;

[0029] Step 2, adding glycerin, antioxidants, deionized water, ultraviolet absorbers, and preservatives to the first mixture, stirring at 300 rpm, and ultrasonically treating at 140 MHz for 15 minutes to obtain the second mixture;

[0030] Step 3, put the second mixture into a twin-...

Embodiment 3

[0032] A formaldehyde absorbing material, comprising the following raw materials in parts by weight: 4 parts of glycerin, 0.8 parts of antioxidant, 14 parts of polystyrene amide, 9 parts of silicon dioxide, 25 parts of 400 mesh plastic powder, 45 parts of deionized water , 4 parts of phenyl o-hydroxybenzoate, 5 parts of carbon fiber, 4 parts of preservative, and 18 parts of glass fiber.

[0033] The preparation method of the adsorption material capable of absorbing formaldehyde comprises the following steps:

[0034] Step 1, mix poly(phenylacrylamide), silicon dioxide, plastic powder, carbon fiber and glass fiber, place in a reaction kettle, and heat at 1200° C. for 16 minutes to obtain the first mixture;

[0035] Step 2, adding glycerin, antioxidants, deionized water, ultraviolet absorbers, and preservatives to the first mixture, stirring at 200-400 rpm, and ultrasonically treating at 150 MHz for 19 minutes to obtain the second mixture;

[0036] Step 3, put the second mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com