Method for preparing phosphorus oxide modified microporous molecular sieve shape-selective catalyst

A technology of microporous molecular sieves and phosphorus oxides, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of harsh conditions, high cost, cumbersome preparation operations, etc., and achieve improved shape selectivity, The effect of low cost and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

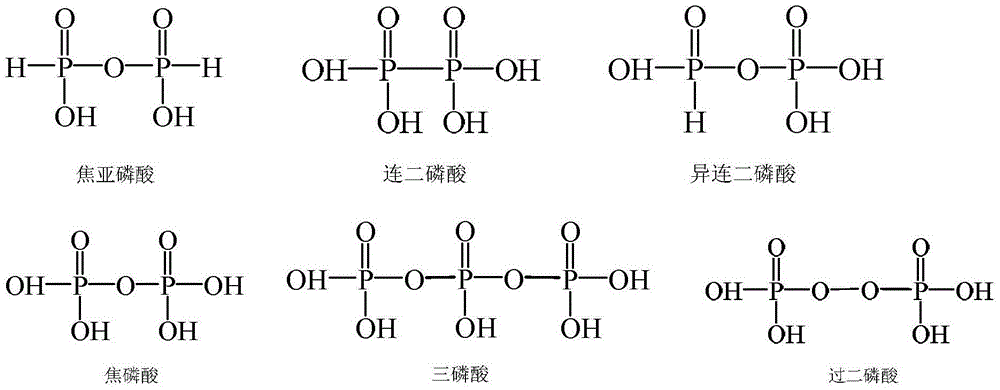

[0016] Add hypophosphoric acid into anhydrous methanol, wherein the mass ratio of hypophosphoric acid to methanol is 1:5, stir until completely dissolved; then add microporous molecular sieve ZSM-5 to the above solution, wherein hypophosphoric acid and microporous molecular sieve The mass ratio was 1:20, stirred evenly, and stood at room temperature for 12 hours; evaporated to dryness in a water bath, then dried in an oven at 120°C for 6 hours, then transferred to a muffle furnace, and dried in an air atmosphere at 10°C The temperature was raised to 600°C at a rate of 1 / min, and kept at this temperature for 4 hours, and then lowered to room temperature to obtain the desired phosphorus oxide-modified microporous molecular sieve shape-selective catalyst, denoted as Cat1.

Embodiment 2

[0018] Add pyrophosphoric acid into anhydrous methanol, wherein the mass ratio of pyrophosphoric acid to methanol is 1:7, and stir until completely dissolved; then add microporous molecular sieve ZSM-5 to the above solution, wherein the mass ratio of pyrophosphoric acid to microporous molecular sieve 1:6, stirred evenly, and stood at room temperature for 12 hours; evaporated the obtained material to dryness in a water bath, then put it in a 120°C oven to dry for 6 hours, and then transferred it to a muffle furnace. The temperature was raised to 600° C. and kept at this temperature for 4 hours, and then lowered to room temperature to obtain the desired phosphorus oxide-modified microporous molecular sieve shape-selective catalyst, denoted as Cat2.

Embodiment 3

[0020] Add pyrophosphorous acid into anhydrous methanol, wherein the mass ratio of pyrophosphorous acid to methanol is 1:10, stir until completely dissolved; then add microporous molecular sieve ZSM-5 to the above solution, wherein pyrophosphorous acid and microporous molecular sieve The mass ratio is 1:6, stirred evenly, and allowed to stand at room temperature for 12 hours; evaporated to dryness in a water bath, then dried in an oven at 120°C for 6 hours, then transferred to a muffle furnace, and heated in an air atmosphere at 10°C The temperature was raised to 600°C at a rate of 1 / min, and kept at this temperature for 4 hours, and then lowered to room temperature to obtain the desired phosphorus oxide-modified microporous molecular sieve shape-selective catalyst, denoted as Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com