Full-automatic high-rate chip LED spectrophotometer

A spectroscopic and color separation machine, fully automatic technology, applied in sorting and other directions, can solve problems such as production progress lag, production and processing process influence, adjustment or maintenance complex and cumbersome, etc., achieve high-speed work efficiency, improve test accuracy, and mechanism Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

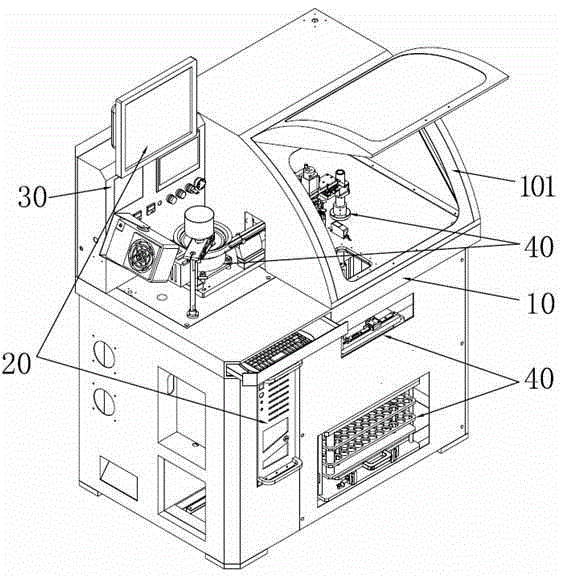

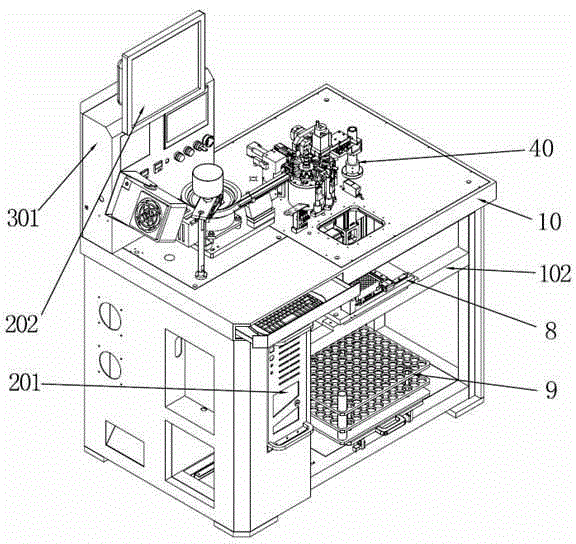

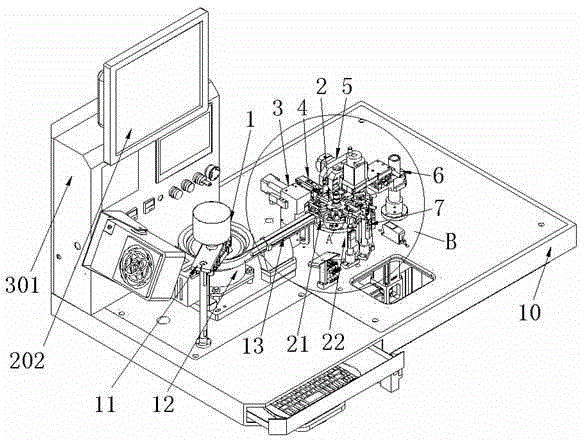

[0043] A full-automatic high-speed SMD LED spectroscopic and color separation machine mainly includes a working frame 10, a detection instrument 20, a control system 30 and a motion system 40, and the detection instrument 20, the control system 30 and the motion system 40 are installed on the working frame 10. On the rack table or inside the rack, the detection instrument 20 is composed of a test computer 201 and an information display 202. The control system 30 is a combination of man-machine combination 301 operation control and PLC programming control, and each mechanism is controlled or adjusted by the PLC board of the system. operation;

[0044] The motion system 40 mainly includes a turntable mechanism 2, and a feeding mechanism 1, a material taking mechanism 3, a positioning mechanism 4, a testing mechanism 5, an integrating sphere mechanism 6, a blowing and blanking mechanism 7, a sorting mechanism 8 and The receiving mechanism 9; the turntable mechanism 2 is mainly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com