Working platform using lighting curing device

A technology of light curing and working platform, applied in the direction of workbench, device for coating liquid on the surface, manufacturing tool, etc., can solve the problems of failure of function, scrapped parts, oxidation of electronic silica gel, etc., and achieve the effect of shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

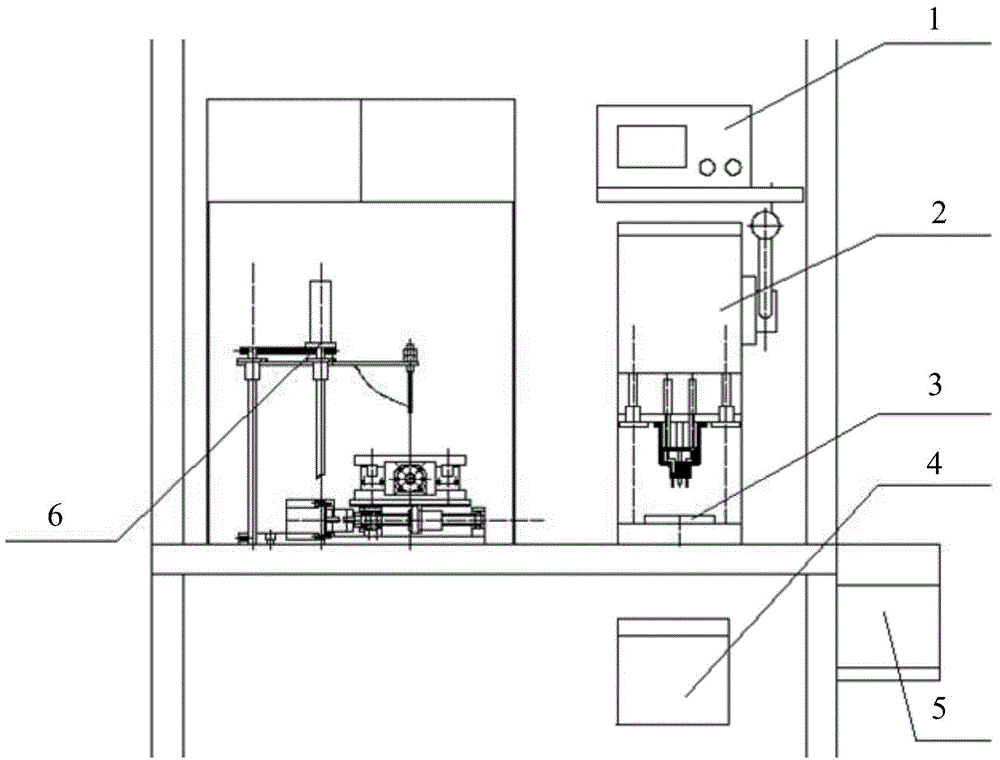

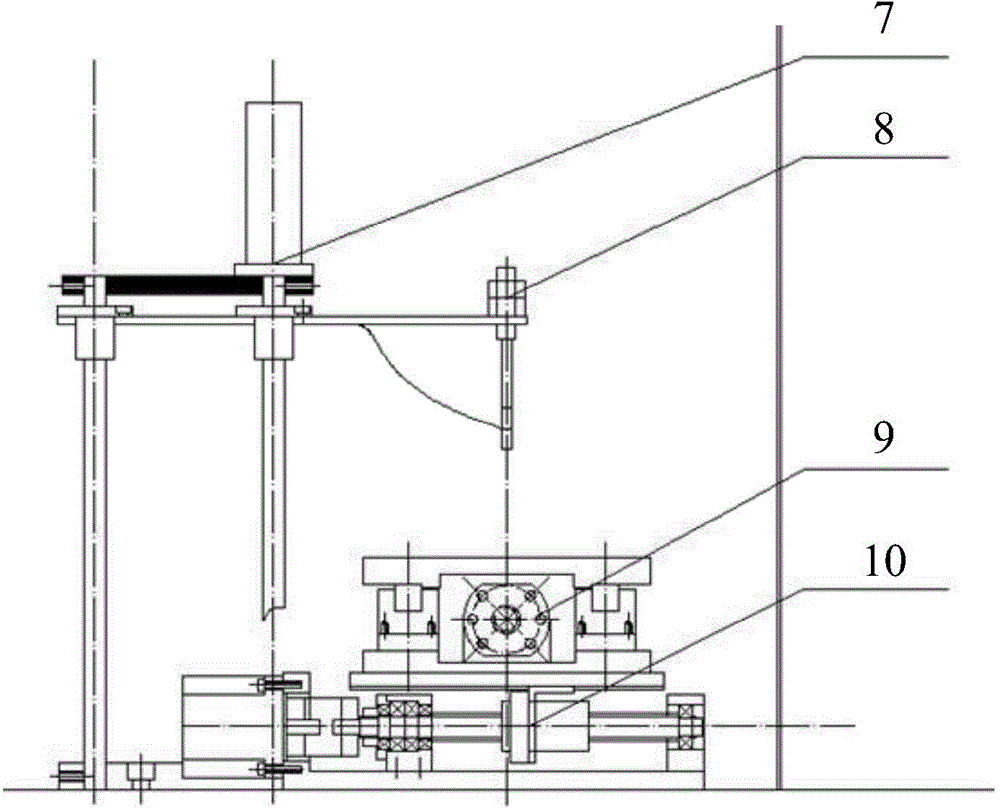

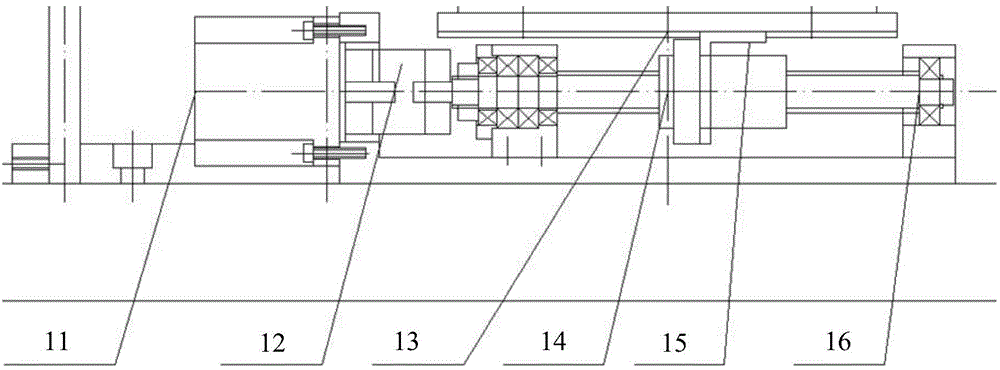

[0015] The following examples refer to Figure 1-6 .

[0016] The working platform using the light curing device of the present invention includes a signal light board 1 , a ceramic substrate parallelism measuring device 2 , a parallelism verification piece 3 , a stacking box for unqualified products 4 , a stacking box for finished products 5 and a light curing device 6 . The ceramic substrate parallelism measuring device 2 is composed of a return spring 17, a gear shaft 18, a gear rod 19, a measuring head 20, etc., and is located at the right end of the entire platform.

[0017] The rightmost end of the platform is a finished product stacking box 5, arranged between this station and the next station, in a box-like structure. The surrounding table is inclined with an inclination angle of at least 45°, and a protective cover is installed above it to prevent the workpiece from being placed on it by mistake. There is a cylinder ejector rod in the box, and the ejector rod will f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com