Device and method for slicing solar silicon wafers

A technology for solar silicon wafers and cutting equipment, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of increasing the cost of replacing mortar and equipment maintenance, affecting the cutting ability of mortar, and turning into waste mortar, etc., to save Resources, low cost of use, and the effect of reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The equipment used includes one NTC PV800 slicer and several plastic or metal materials.

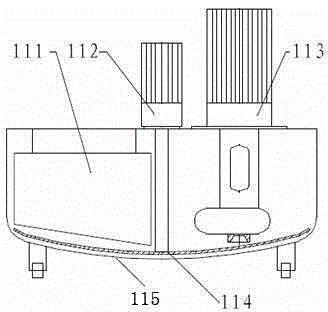

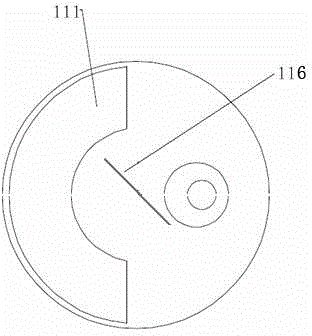

[0019] Such as figure 1 and figure 2 as shown,

[0020] a. Make a fixed-volume sealed semi-circular buoy 111 using plastic or metal materials, the outer diameter of the buoy 111 is 1000 cm, and the inner diameter of the buoy 111 is 400 cm.

[0021] b. Fix the buoy 111 on the top left side in the slurry tank 115 of the slicer PV800, so that the mortar stirring blades 114 and 116 in the slurry tank can operate normally;

[0022] c. Monitor whether there is residual waste slurry in the slurry tank, and clean it up, and then add 500KG new mortar in the slurry tank 116;

[0023] d. Install the silicon block and start the NTC PV800 slicer, the mortar in the slurry tank will be fully recycled automatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com