Three-dimensional biological printing device and method

A technology of 3D biological and printing devices, applied in the field of 3D printing, can solve the problems of poor delamination of 3D structures, unsuitable printing of 3D biological structures, and easy contamination of 3D structures, and achieve rapid chemical cross-linking and solidification, separation Good layer effect and stable structure of each layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

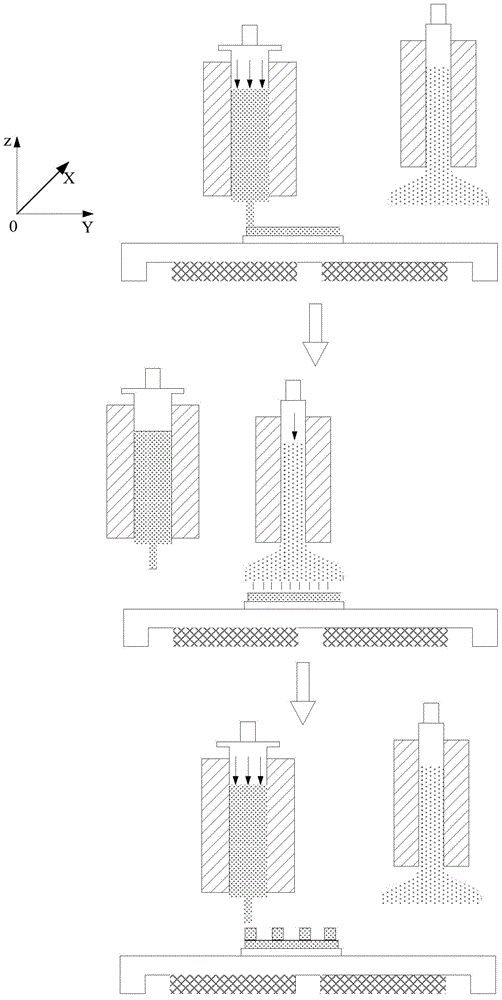

[0016] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

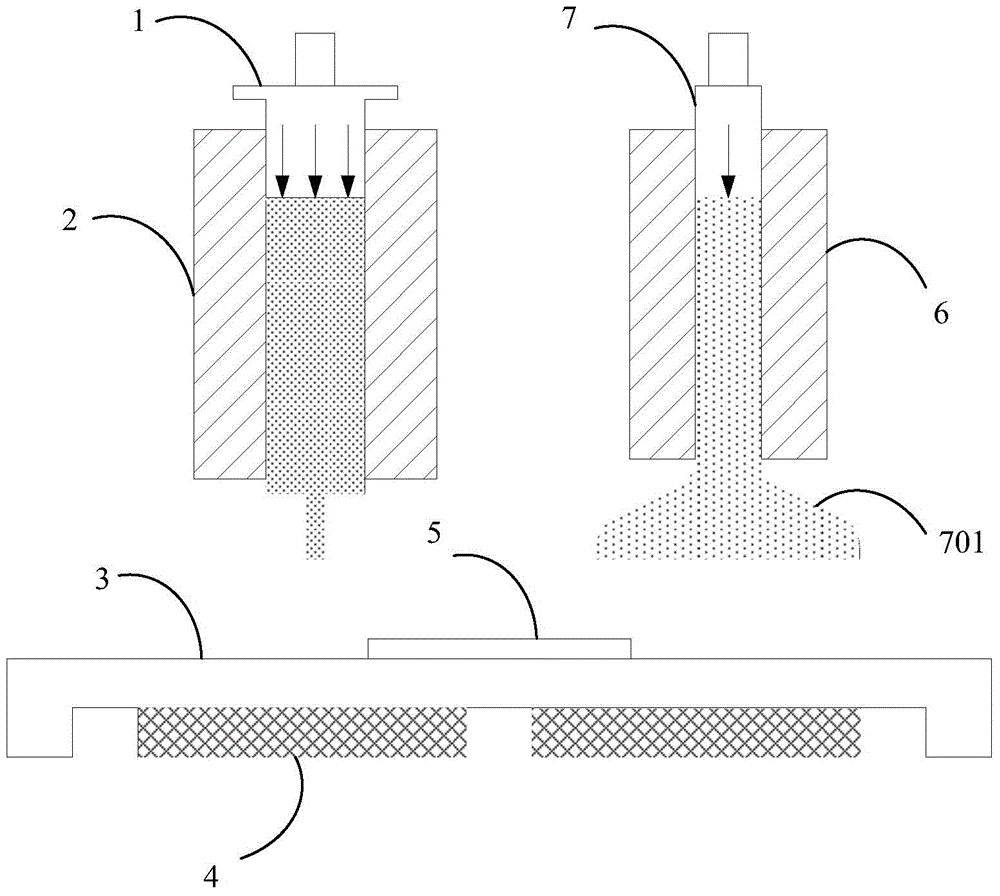

[0017] Such as figure 1 Shown is a schematic structural view of the three-dimensional bioprinting device of this specific embodiment. The three-dimensional bioprinting device includes a printing nozzle 1 , a first temperature control module 2 , an auxiliary material nozzle 7 , a forming platform 3 and a semiconductor cooling chip 4 .

[0018] Wherein, the print nozzle 1 is filled with a sol-state temperature-sensitive material solution, which is ejected and printed onto the forming platform 3 . For example, to print a scaffold-like three-dimensional structure, the printing nozzle 1 is filled with hydrogel of biomaterials (including natural biomaterials and synthetic biomaterials). For example, to print a cell-like three-dimensional structure, the printing nozzle 1 is loaded with a cell-like material hydrogel. 5 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com