Disposable indication steam sterilizing packaging material

A packaging material, steam sterilization technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problem of difficult attachment of inorganic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

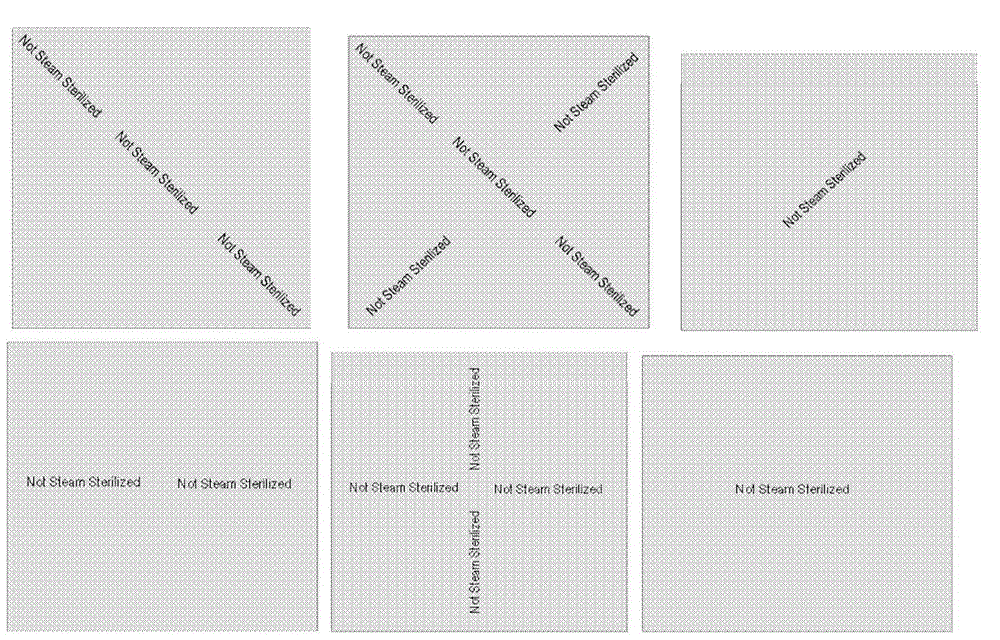

[0052] The waxy material POLYWAX TM 850 (hydrocarbon wax, Baker Hughes) and black pigment PRINTEX 25 (carbon black, Evonik Degussa) were mixed at a mass ratio of 65:35 to form a colored phase change material 1 with a melting point of 100-110°C.

[0053] The colored phase change material 1 was melt-jet printed on the SMS non-woven fabric of white polypropylene at a temperature of 130°C. The size of the printed text is "No. 11".

[0054] Make a sterilization bag with the above-mentioned indicating non-woven bag, put it into a sterilizer at a temperature of 134° C., and sterilize it with pressure steam for 3.5 minutes. Then take out the package and observe the appearance of the indicator.

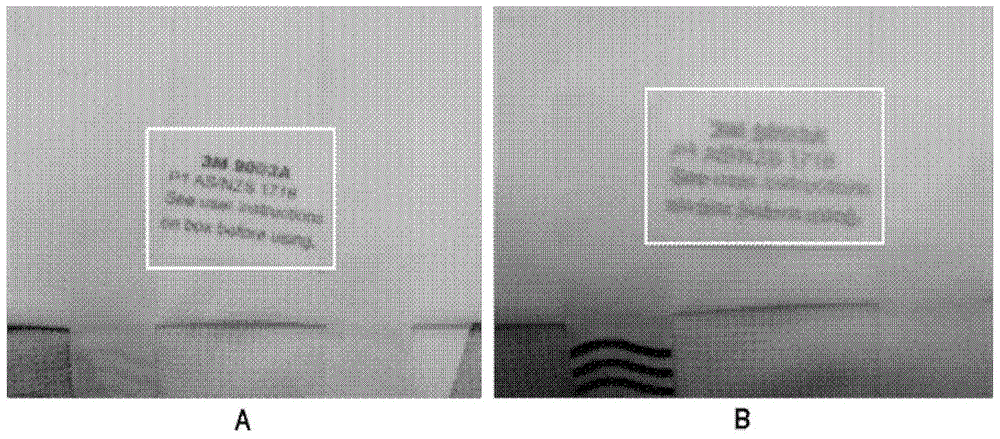

[0055] Such as figure 2 As shown, it can be seen that the initially clearly printed text becomes blurred and unreadable after sterilization. This indicates that the sterilization pack has been sterilized and that the nonwoven has been used.

Embodiment 2

[0057] The waxy material CERAMER TM 1608 (hydrocarbon wax grafted with maleic anhydride, Baker Hughes) and yellow pigment Permanent Yellow P-GRL06 (Permanent Yellow, Clariant) are mixed in a mass ratio of 30:70, and then dissolved in xylene solvent to form a colored phase Change material 2.

[0058] The colored phase change material 2 is printed on the polylactic acid blue SMS non-woven fabric. The size of the printed text is "No. 11".

[0059] Make a sterilization bag with the above-mentioned indicating non-woven bag, put it into a sterilizer at a temperature of 121° C., and sterilize it by pressure steam for 15 minutes. Then take out the package and observe the appearance of the indicator.

[0060] Similar to Example 1, it can be seen that the initially clearly printed characters become blurred and cannot be read after sterilization. This indicates that the sterilization pack has been sterilized and that the nonwoven has been used.

Embodiment 3

[0062] The waxy material POLYWAX TM 2000 (hydrocarbon wax, Baker Hughes) and red pigment Irgalite Red CBNL (BASF, BASF) are mixed in a mass ratio of 50:50 to form a colored phase change material 3 with a melting point of 120-130°C.

[0063] The colored phase change material 3 was melt-jet printed on polypropylene white SMS non-woven fabric at a temperature of 150°C. The size of the printed text is "No. 11".

[0064] Make a sterilization bag with the above-mentioned indicating non-woven bag, put it into a sterilizer at a temperature of 135° C., and sterilize it with pressure steam for 10 minutes. Then take out the package and observe the appearance of the indicator.

[0065] Similar to Example 1, it can be seen that the initially clearly printed characters become blurred and cannot be read after sterilization. This indicates that the sterilization pack has been sterilized and that the nonwoven has been used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com