Broken chain monitor device and method for coal face scraper conveyer

A technology of scraper conveyor and coal mining face, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., and can solve problems such as uneven bottom cutting, large damping, and influence on the accuracy of measurement values of coal shearers , to achieve the effect of reducing maintenance intensity, prolonging service life and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

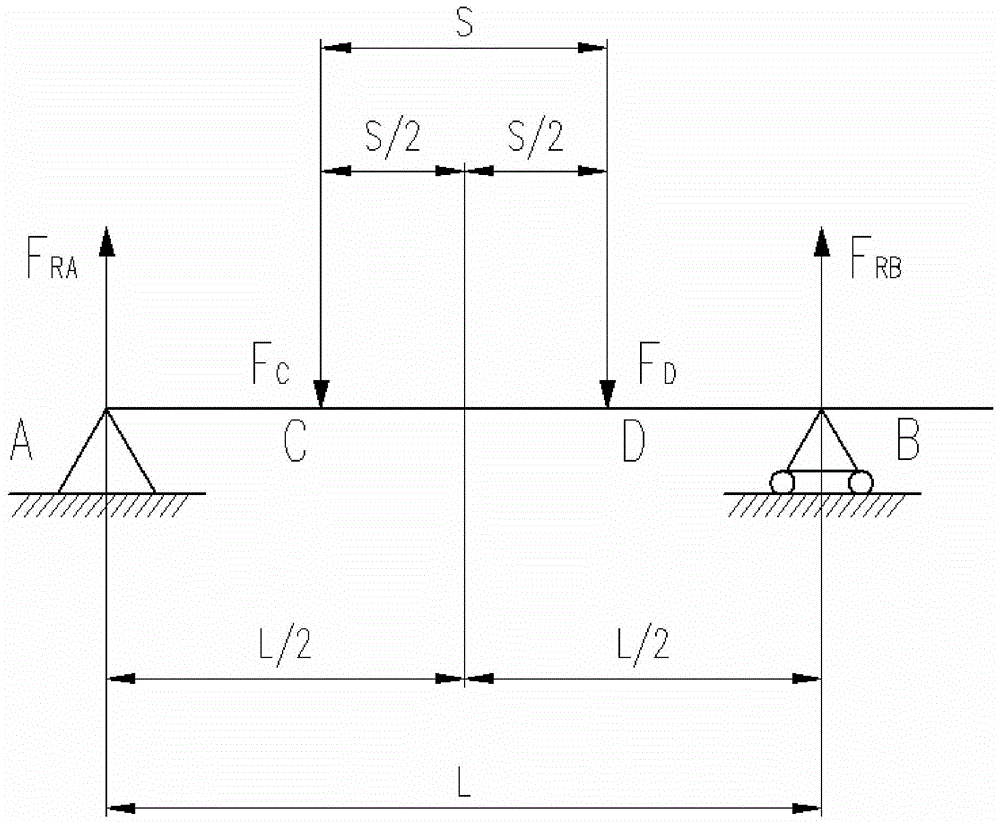

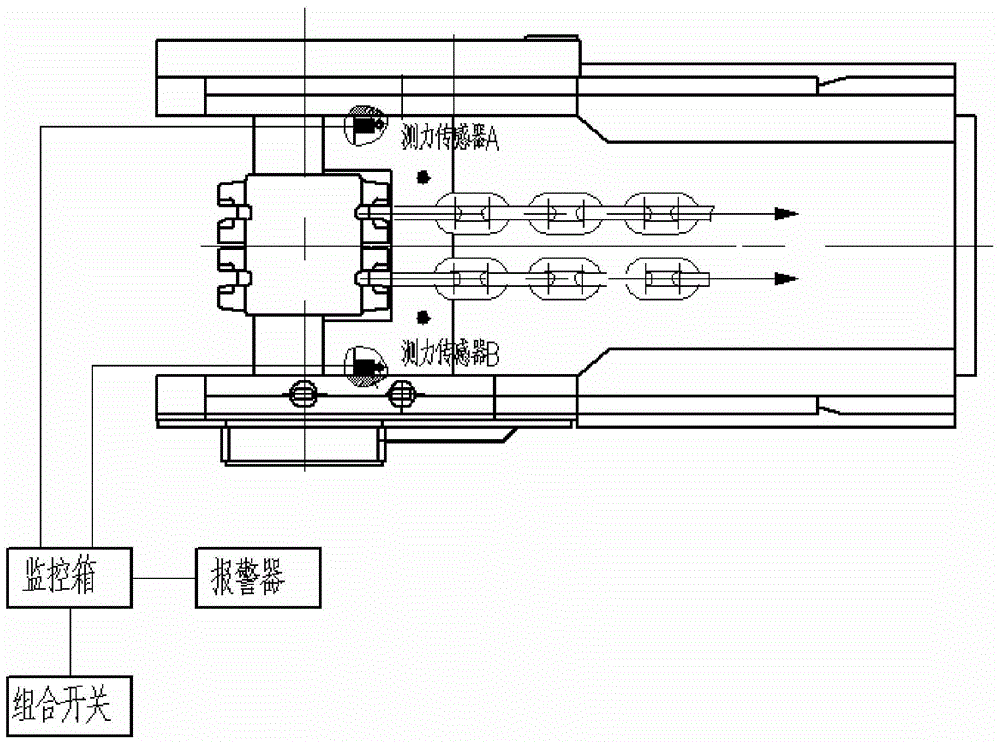

[0014] Such as figure 1 , 2 As shown, the present invention provides a kind of monitoring device of the broken chain of scraper conveyor in coal mining face, including the pressure load sensor installed on the two arc blocks of the head frame of scraper conveyor (each arc block is equipped with a sensor , a total of 2 sensors), so as to measure the pressure signal between each arc block and the bearing seat of the sprocket shaft group during the operation of the scraper conveyor. The pressure load sensor is also connected to the PLC in the monitoring box of the scraper conveyor. The PLC is also connected with the head motor and the tail motor of the scraper conveyor through a combination switch. There is also a PLC in the monitoring box, the PLC collects signals through the pressure load sensor, outputs instructions to the combination switch after calculation and processing, and the data is also connected to the man-machine interface through the MPI interface. The monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com