Rotary machine with direct drive

A technology of rotary machines and rotating parts, applied in conveyors, electromechanical devices, structural connections, etc., can solve problems such as misalignment of gear backlash, complex lubrication of tooth connections, difficulty in meeting high-precision requirements, etc., to achieve low wear and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

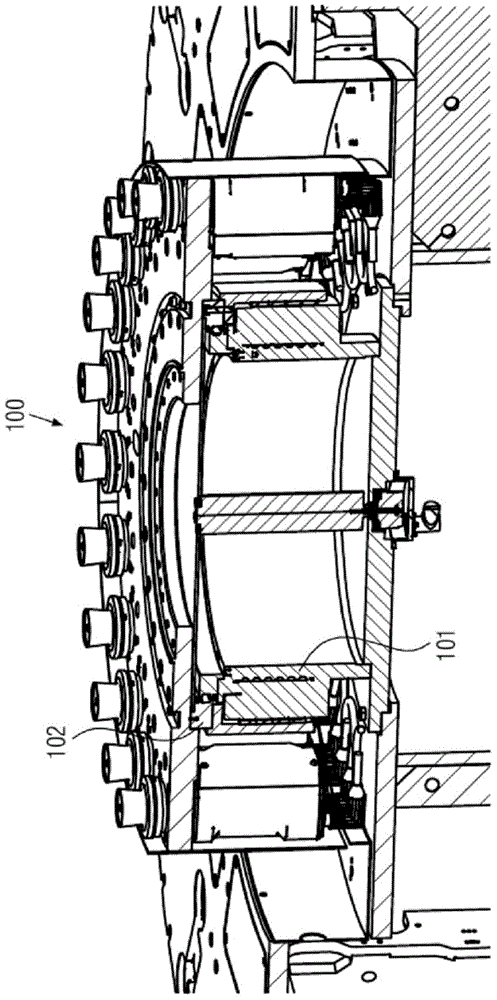

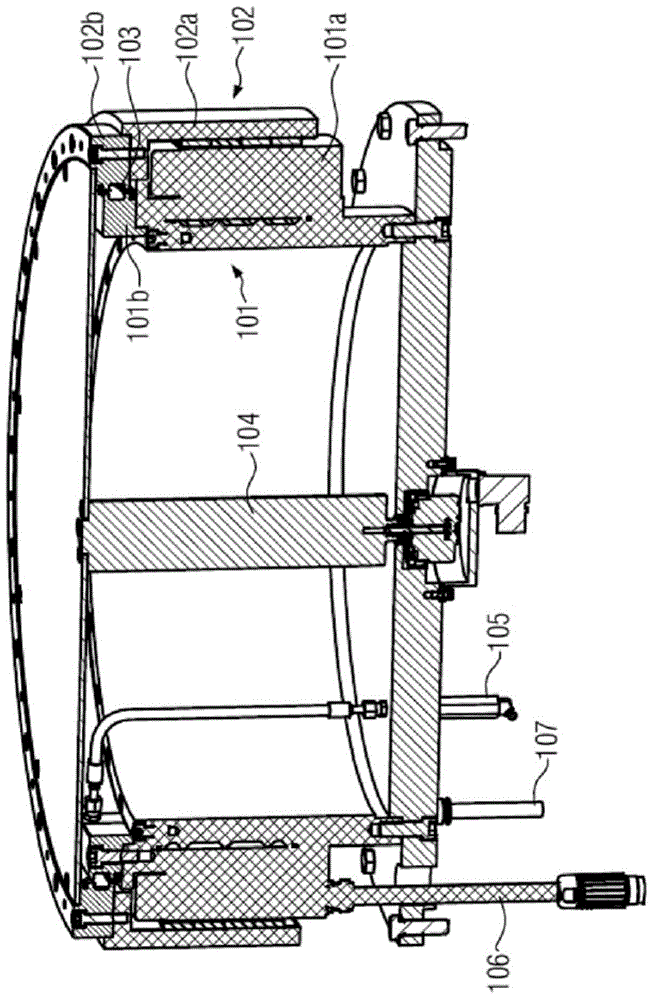

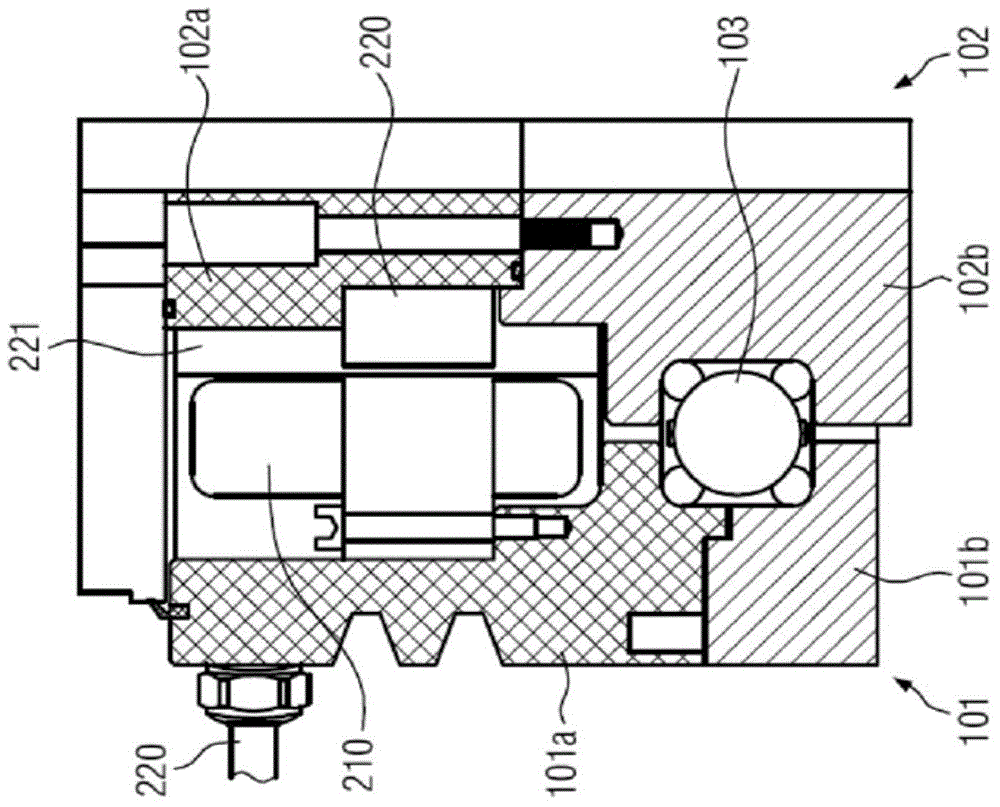

[0028] Figure 1a A rotary machine 100 according to the invention is shown. It includes a fixed part 101 and a rotating part 102 . Typically, container handling stations or container gripping stations or elements for securing the containers or container transport elements are arranged on the rotary section 102 . Depending on the embodiment of the rotary machine 100, these can vary widely. As an example, the rotary section in a direct printer includes several container handling stations or container gripping stations. The latter may, for example, comprise respective carousels and printing modules associated therewith. Depending on the design of the rotary machine, other components such as ink tanks, labeling or printing units, etc. can be arranged at the fixed part 101 of the rotary machine. Here, various different embodiments are known which may depend on the type of container handling machine.

[0029] Basically, the fixed part 101 and the rotating part 102 are interconn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com