A device for producing silicon and silicon nitride nanoparticles

A nanoparticle and silicon nitride technology, which is applied in nanotechnology, nitrogen compounds, nanotechnology, etc. for materials and surface science, can solve the problems of low gas production rate, uneven distribution of electromagnetic field, and incapable of mass production, etc., and achieve improvement Productivity, the realization of large-scale industrial production, and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

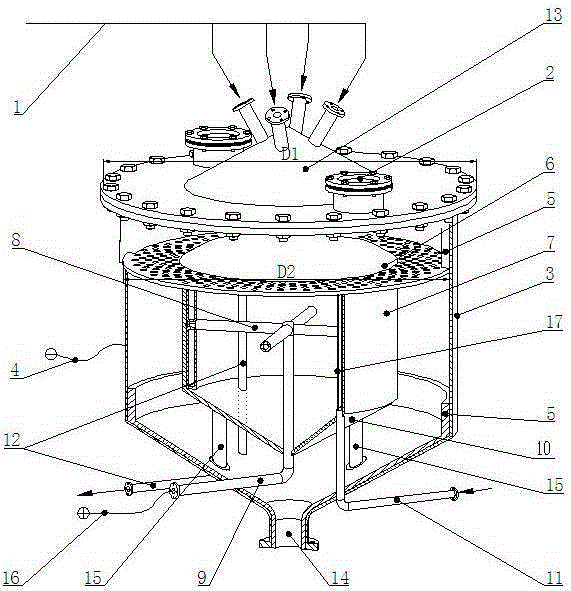

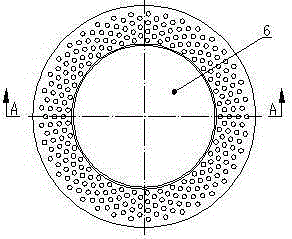

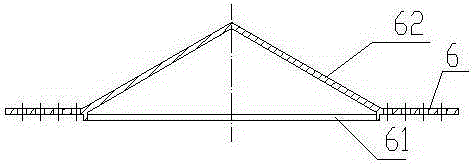

[0023] Description of reference signs: air inlet 1, observation window 2, anode 3, anode ground wire 4, polytetrafluoroethylene 5, quartz cover 6, solid cylinder 61, protruding cone 62, cathode 7, cathode wire 8, vacuum Electrode 9, cathode support 10, cooling water inlet 11, cooling water outlet 12, air inlet cover 13, air outlet 14, steel rod 15, cathode connection 16.

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] This device is figure 1 As shown, the barrel-shaped outer wall is used as the anode 3, and the barrel can be made of stainless steel, that is, the anode 3 is made of stainless steel, and the inner surface of the barrel is covered with Si 3 N 4 (silicon nitride) coating. Such as figure 1 As shown, there are four symmetrically distributed gas inlets 1 on the air inlet cover 13 of the barrel-shaped outer wall, and the four air inlets 1 are arranged above the protruding cone on the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com