Molybdenum oxide nanoparticle production device and production method

A nanoparticle and production device technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, nanotechnology, nanotechnology, etc., can solve problems such as low efficiency, complicated process, unstable product quality, etc., achieve no environmental pollution, improve gasification The effect of conversion rate and ease of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

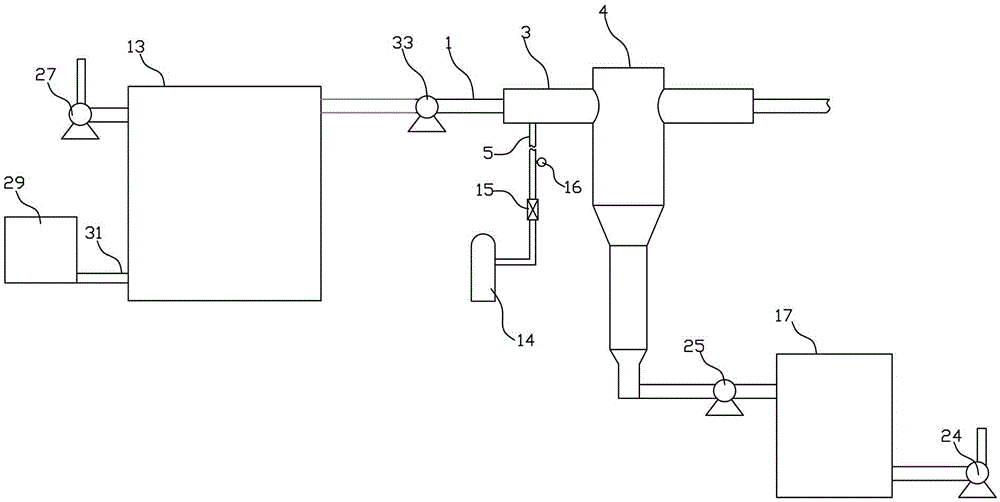

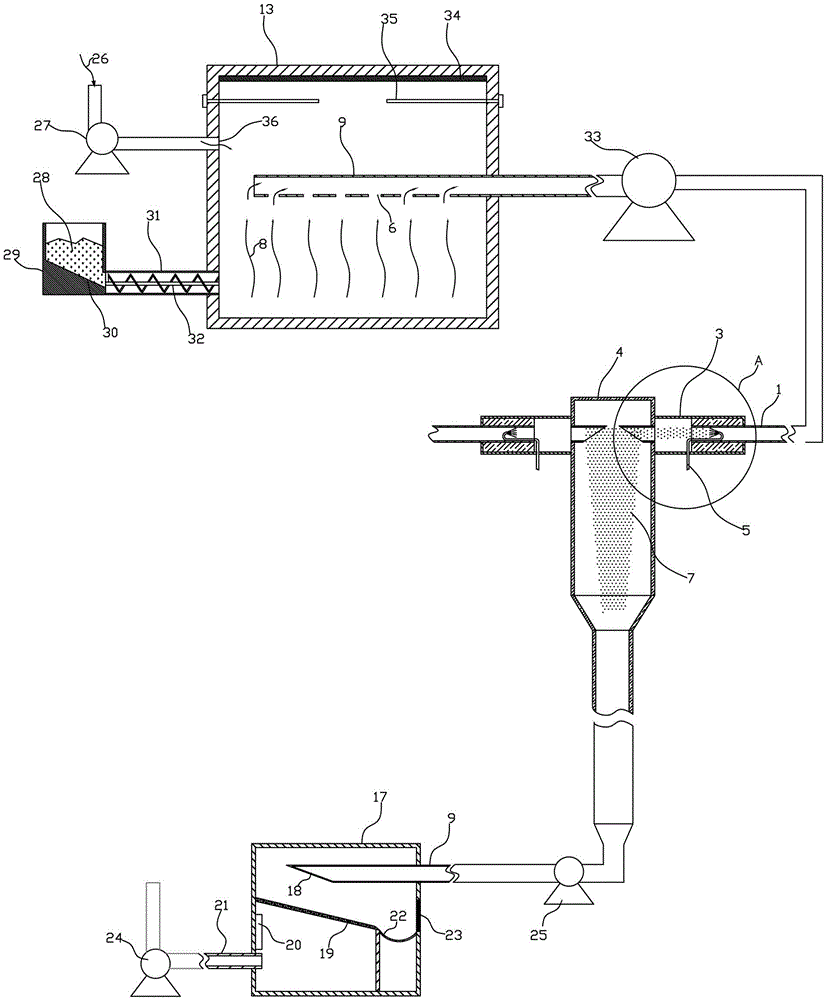

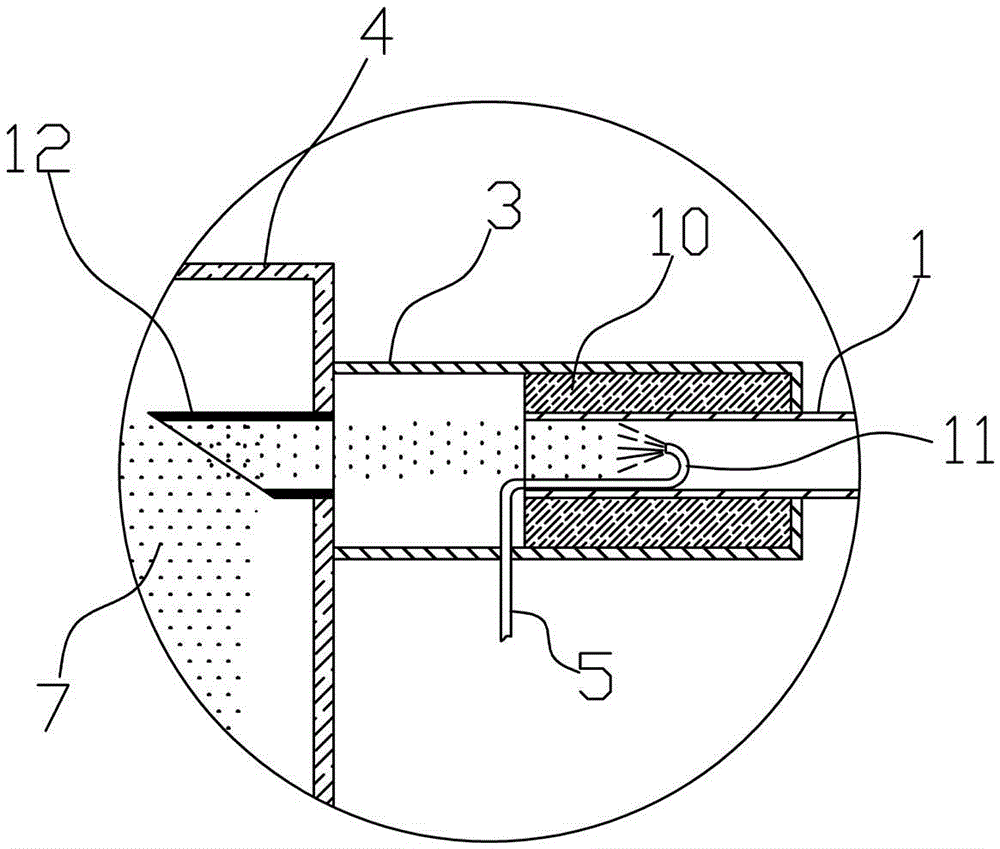

[0046] Embodiment 1: A kind of molybdenum oxide nanoparticle production device, and production method, see figure 1 , figure 2 , image 3 The device includes a gasification unit for gasifying the precursor material of molybdenum oxide nanoparticles, a quenching unit for quenching the gasified molybdenum oxide nanoparticles, and collecting molybdenum oxide nanoparticles Finished product collection unit.

[0047] The gasification unit includes a gasification furnace, and the gasification furnace includes a furnace body 13 with a closed cavity inside, and four electric heating elements correspondingly arranged in the furnace body for raising the temperature of the furnace body. body 35; the gasification unit also includes a feeding mechanism for delivering precursor materials to the furnace body; further, an air inlet 36 communicating with the outside is provided on the upper side wall of the furnace body, and at the same time, The gasification furnace also includes a second ...

Embodiment 2

[0052] Embodiment 2: the method for producing molybdenum oxide nanoparticles using the above-mentioned molybdenum oxide nanoparticle production device, see figure 1 , figure 2 , image 3 ; it includes the following steps:

[0053] a. Raise the temperature in the gasifier to between 1150°C and 1210°C;

[0054] b. turn on the second blower 27, negative pressure blower 33, blower 25, exhaust fan 24 in turn;

[0055] c. Open the valve so that the quenching liquid is ejected from the end outlet of the quenching liquid pipe;

[0056] d. Sending the precursor material of molybdenum oxide nanoparticles into the gasifier;

[0057]Before performing step (d), the temperature in the gasifier should be kept between 1150 ° C and 1210 ° C for 8-10 minutes; at the same time, the end outlet of the quenching liquid pipe should be sprayed out when performing step (c) The pressure of the quenching liquid is kept at 4.0-5.3Pa; and the suction capacity of the exhaust fan 24 is kept at 1000-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com