Mesh-net type glass bottle annealing furnace

A glass bottle and mesh belt type technology, applied in the field of mesh belt type glass bottle annealing furnace, can solve the problems of uneven temperature difference change, fast damage of heating device, and too much heat loss at the front end of the furnace body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

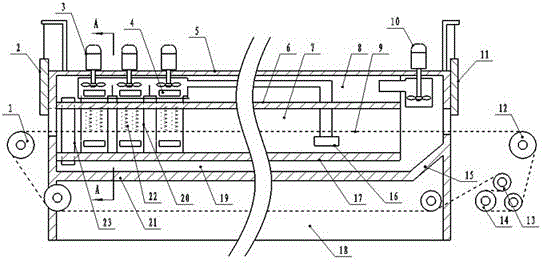

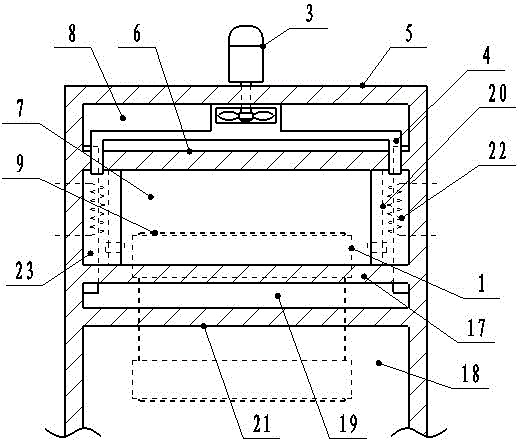

[0007] Embodiment one: if figure 1 and figure 2 As shown, a mesh-belt type glass bottle annealing furnace, the furnace body 5 is in the shape of a long strip, and the outer insulation wall is built. , the rear insulation door 11 is installed on the port, and the middle and lower part of the body of furnace 5 is provided with an interlayer 21. The interlayer 21 divides the body of furnace into a heat preservation chamber 7 and a mesh belt rotary chamber 18, and the front end of the mesh belt 9 is installed on the front end of the body of furnace. On the front guide roller 1, the rear end of the mesh belt is installed on the rear mesh roller 12, the tension roller 14 and the driving roller 13 at the rear end of the furnace body, the upper surface of the mesh belt 9 passes through the heat preservation cavity 7, and the lower mesh surface passes through the The mesh belt passes through the rotary cavity 18, and heating devices 22 are installed on both sides of the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com