A preparation method of porous carbon material anti-oxidation coating

A technology of porous carbon material and anti-oxidation coating is applied in the field of preparation of anti-oxidative coating of porous carbon material to achieve the effect of improving anti-oxidation performance and anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] As mentioned above, the present invention provides a method for preparing an anti-oxidation coating of a porous carbon material, which may include the following steps: (1) preparing an anti-oxidation precursor solution; (2) impregnating the porous carbon material in an anti-oxidation coating (3) solvent-assisted deposition of antioxidant precursors; (4) drying and curing; and (5) pyrolysis. Preferably, the drying is carried out by means of supercritical drying; in addition, it is preferable that the curing is carried out by means of heat and pressure.

[0026] In some embodiments, the method of the present invention comprises the steps of:

[0027] (1) Prepare an antioxidant precursor solution by using an antioxidant precursor and a first solvent;

[0028] (2) impregnating the porous carbon material with the antioxidant precursor solution;

[0029] (3) soaking the impregnated porous carbon material in the second solvent, so that the precursor is deposited in the porou...

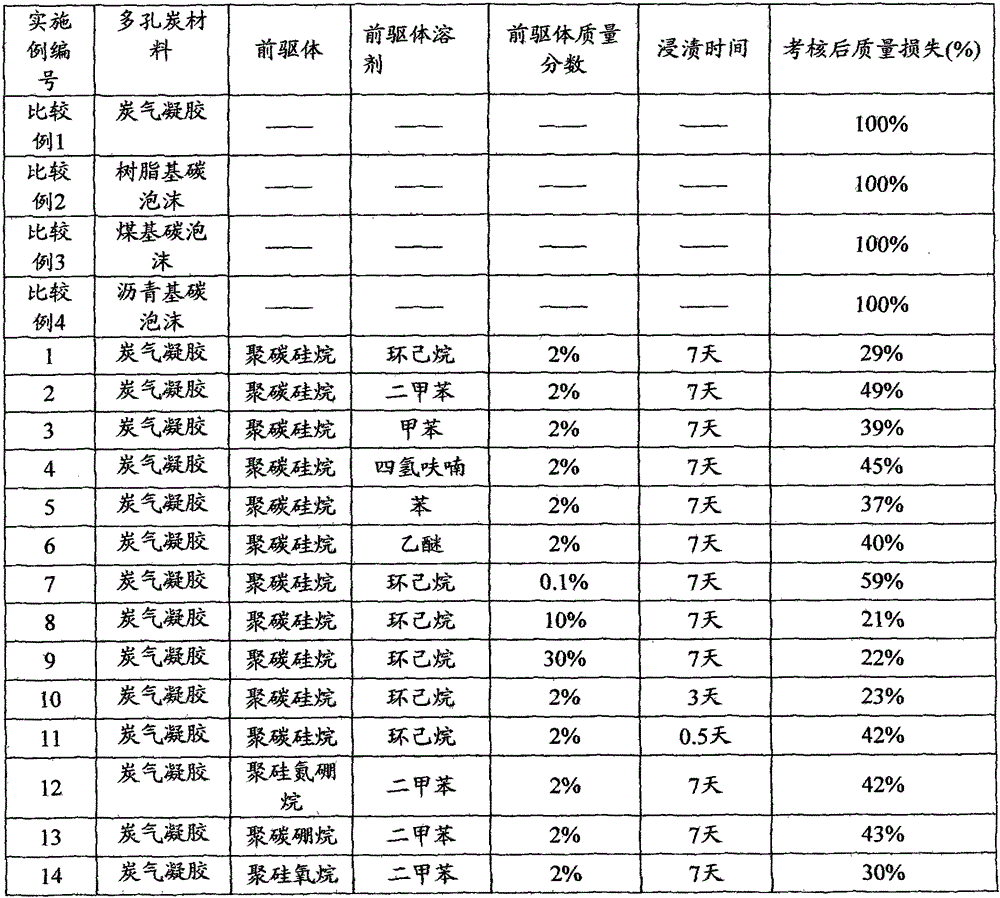

Embodiment 1

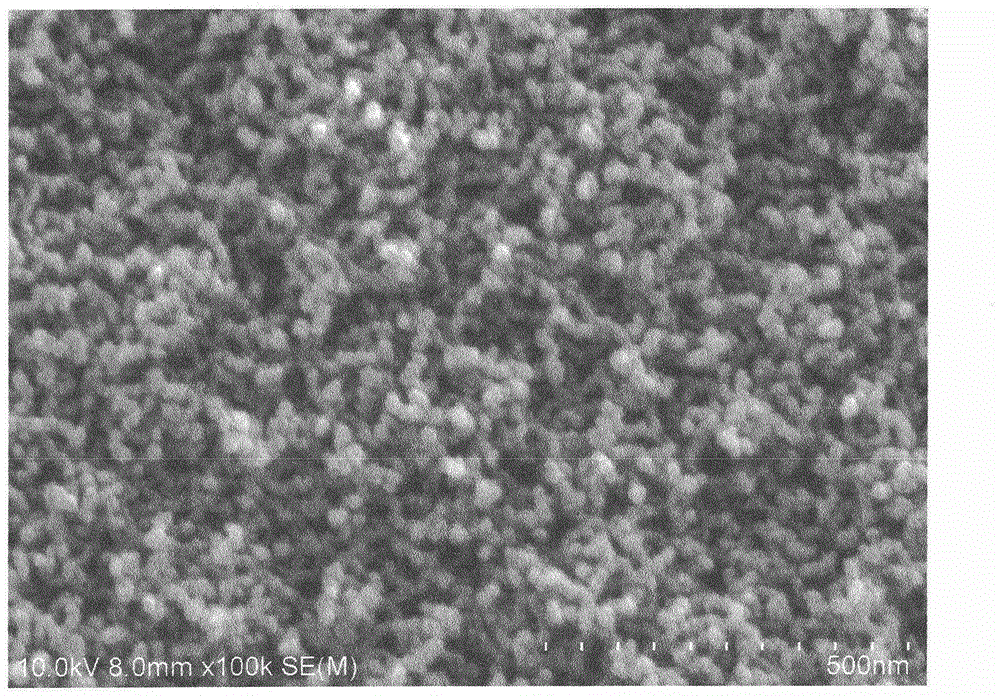

[0054] Polycarbosilane was dissolved in cyclohexane to prepare a polycarbosilane solution with a mass concentration of 2%. Fix the carbon airgel in the sealing tooling, vacuumize, the vacuum degree is -0.05MPa, keep it for 20min, then inject the polycarbosilane solution into the carbon airgel, and pressurize to 0.2MPa, the impregnation time is 7 days, The polycarbosilane solution can fully enter the porous structure of the carbon airgel.

[0055] After impregnation, the pressure-impregnated carbon airgel was placed in excess acetone as the second solvent for solvent-assisted deposition. After the solvent-assisted deposition is completed, supercritical drying is carried out again, and the temperature of the drying kettle of the supercritical equipment is raised to 50°C±6°C, and the pressure is maintained at 10-14MPa. The sample after supercritical drying was heated and cured under a pressure of 0.2MPa. The curing conditions were: from room temperature to 200°C, the heating rat...

Embodiment 2

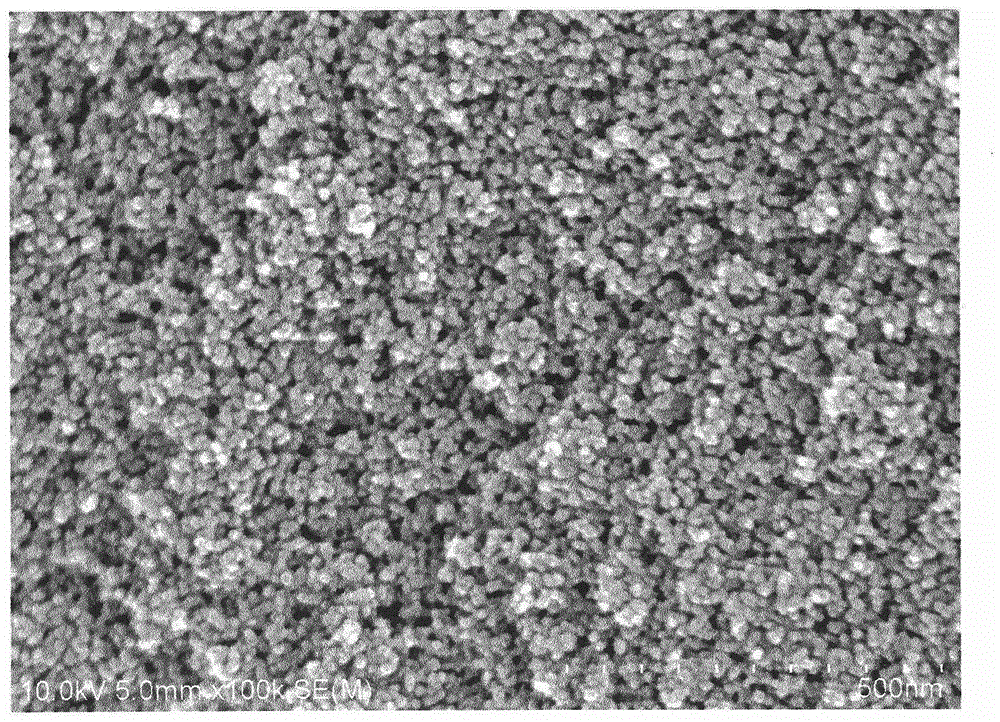

[0059] Polycarbosilane was dissolved in xylene to prepare a polycarbosilane solution with a mass concentration of 2%. Fix the carbon airgel in the sealing tooling, vacuumize, the vacuum degree is -0.05MPa, keep it for 20min, then inject the polycarbosilane solution into the carbon airgel, and pressurize to 0.2MPa, the impregnation time is 7 days, The polycarbosilane solution can fully enter the porous structure of the carbon airgel.

[0060] After impregnation, the pressure-impregnated carbon airgel was placed in excess acetone as the second solvent for solvent-assisted deposition. After the solvent-assisted deposition is completed, supercritical drying is carried out again, and the temperature of the drying kettle of the supercritical equipment is raised to 50°C±6°C, and the pressure is maintained at 10-14MPa. The sample after supercritical drying was heated and cured under a pressure of 0.2MPa. The curing conditions were: from room temperature to 200°C, the heating rate was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com