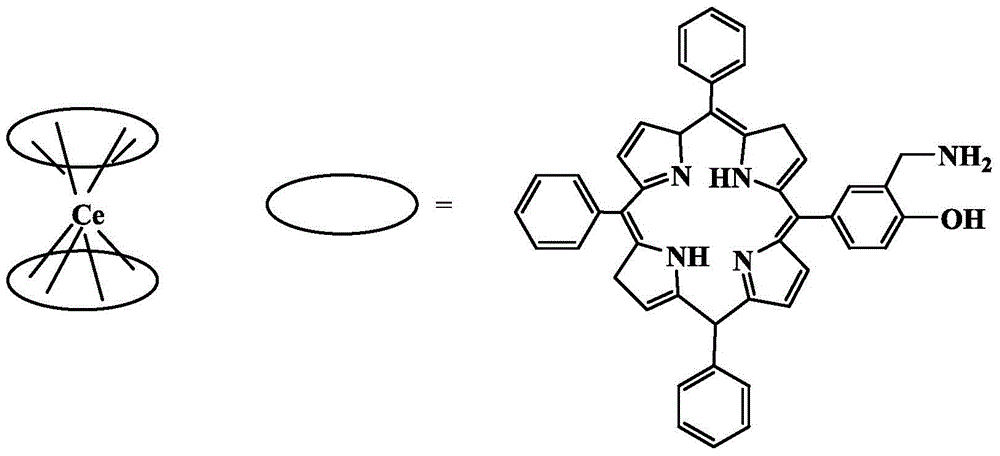

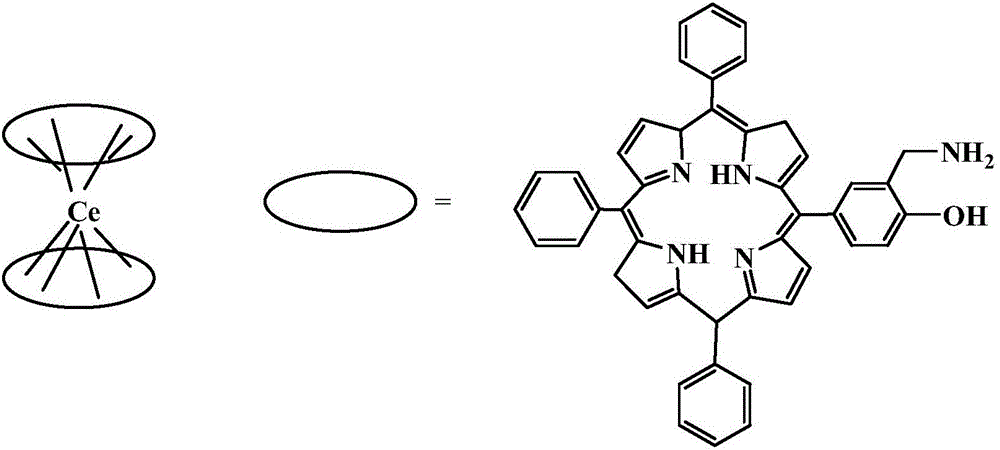

A water-soluble double-layer sandwich-type CE metalloporphyrin complex and its application in microcontact printing technology

A micro-contact printing, sandwich-type technology, applied in the field of modern electronics, can solve the problems of unreported application and achieve the effect of easy-to-obtain raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Substrate surface treatment: ultrasonically clean the polyimide substrate with ethanol for 1 hour, take it out and dry it in vacuum at 80°C. After drying, place the polyimide substrate in 1% vinyl tris(β-methoxy Soak in ethoxy)silane solution for 24 hours, take out the ethanol and ultrasonically clean it for 1 hour, take it out and place it in vacuum drying at 80°C, the mass percentage of ethanol and polymer substrate is 1:1, 100g of polyimide substrate, 1.5 1 g of methacrylic acid, 0.1 g of azobisisobutyronitrile and 500 ml of distilled water were put into a three-neck flask together, and reacted for 1 hour at a temperature of 80° C. to obtain a carboxylated polyimide substrate;

[0031] 2) Preparation of an aqueous solution of bis(5-(4'-hydroxyl-3'-aminomethylphenyl)-10,15,20-triphenylporphyrin) with Ce: Di(5-(4'-hydroxyl -3'-aminomethylphenyl)-10,15,20-triphenylporphyrin) with Ce dissolved in water to obtain bis(5-(4'-hydroxyl-3'-aminomethyl) with a concentration ...

Embodiment 2

[0036]1) Substrate surface treatment: ultrasonically clean the polytetrafluoroethylene substrate with ethanol for 2 hours, take it out and dry it in vacuum at 90°C. After drying, place the polytetrafluoroethylene substrate in 3% vinyl tris(β-methoxy Soak in ethoxy)silane solution for 36 hours, take out the ethanol and ultrasonically clean it for 2 hours, take it out and place it in 90°C for vacuum drying, the mass percentage of ethanol and polymer substrate is 1:5, 300g of polytetrafluoroethylene substrate, 3g methacrylic acid, 0.1g of azobisisobutyronitrile and 800ml of distilled water were put into a three-neck flask together, and reacted at a temperature of 90°C for 2 hours to obtain a carboxylated polytetrafluoroethylene substrate;

[0037] 2) Preparation of an aqueous solution of bis(5-(4'-hydroxyl-3'-aminomethylphenyl)-10,15,20-triphenylporphyrin) with Ce: Di(5-(4'-hydroxyl -3'-aminomethylphenyl)-10,15,20-triphenylporphyrin) with Ce dissolved in water to obtain bis(5-(4'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com