Preparation device and method of nanoparticle functional slurry for fluorocarbon coatings

A technology of nano-particles and fluorocarbon coatings, applied in chemical/physical/physicochemical processes, chemical instruments and methods, coatings, etc. that apply energy. It can solve the problem of severe local reactions, non-use of constant temperature devices, and uniform packaging of modified substances. Insufficient effect and other problems, to achieve good wrapping effect and improve dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

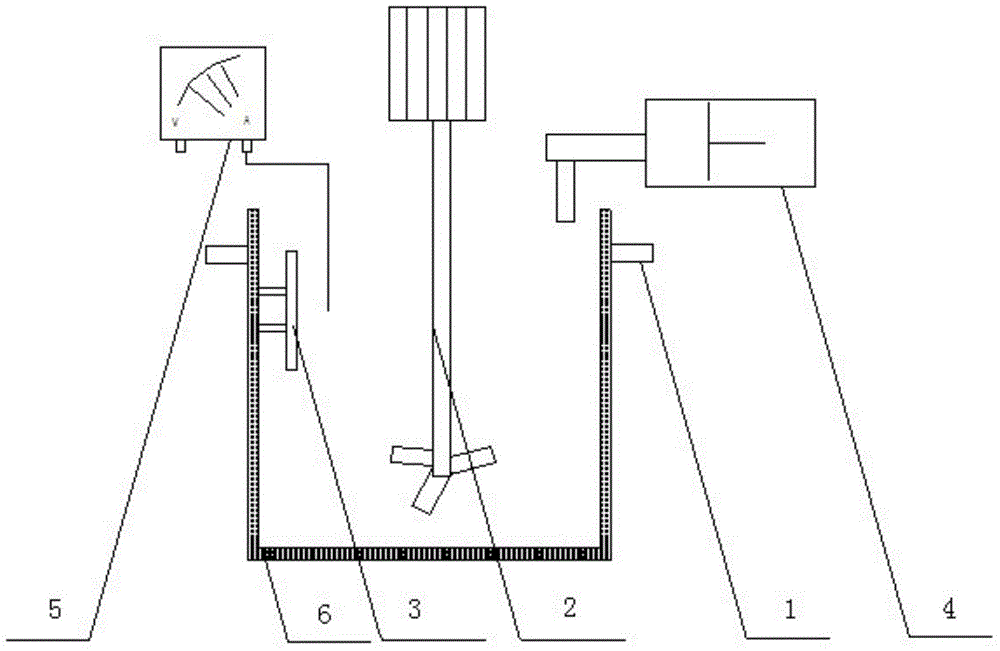

[0023] A preparation device for nanoparticle functional slurry for fluorocarbon coatings, which has a reactor 1, a stirring shaft 2, and an ultrasonic generator 3 is an ultrasonic rod suspended in the reactor 1 in the upper part of the reactor 1; A metering pump 4 is arranged outside the kettle 1, and the discharge port of the metering pump 4 faces the opening of the reaction kettle 1; a current and voltage meter 5 is also provided, and the measuring device of the current and voltage meter 5 extends into the reaction kettle, and the device also has The constant temperature device 6 is a constant temperature water bath.

[0024] Use this device to prepare nanoparticle functional slurry for fluorocarbon coatings:

[0025] 1) Add nanoparticles into the reactor 1, then turn on the stirring shaft 2 and the ultrasonic generator 3, set the stirring frequency to 1500r / min; set the ultrasonic frequency to 60KHZ;

[0026] 2) Set the constant temperature water bath in the constant tempe...

Embodiment 2)

[0029] See figure 1 A preparation device for nanoparticle functional slurry for fluorocarbon coatings, which has a reactor 1, a stirring shaft 2, and an ultrasonic generator 3 is an ultrasonic rod suspended in the reactor 1 in the upper part of the reactor 1; A metering pump 4 is arranged outside the kettle 1, and the discharge port of the metering pump 4 faces the opening of the reaction kettle 1; a current and voltage meter 5 is also provided, and the measuring device of the current and voltage meter 5 extends into the reaction kettle, and the device also has The constant temperature device 6 is a constant temperature water bath.

[0030] Use this device to prepare nanoparticle functional slurry for fluorocarbon coatings:

[0031] 1) Add nanoparticles into the reactor 1, then turn on the stirring shaft 2 and the ultrasonic generator 3, set the stirring frequency to 1500r / min; set the ultrasonic frequency to 60KHZ;

[0032] 2) Set the constant temperature water bath in the ...

Embodiment 3)

[0035] See figure 1 A preparation device for nanoparticle functional slurry for fluorocarbon coatings, which has a reactor 1, a stirring shaft 2, and an ultrasonic generator 3 is an ultrasonic rod suspended in the reactor 1 in the upper part of the reactor 1; A metering pump 4 is arranged outside the kettle 1, and the discharge port of the metering pump 4 faces the opening of the reaction kettle 1; a current and voltage meter 5 is also provided, and the measuring device of the current and voltage meter 5 extends into the reaction kettle, and the device also has The constant temperature device 6 is a constant temperature water bath.

[0036] Use this device to prepare nanoparticle functional slurry for fluorocarbon coatings:

[0037] 1) Add nanoparticles into the reactor 1, then turn on the stirring shaft 2 and the ultrasonic generator 3, set the stirring frequency to 1500r / min; set the ultrasonic frequency to 60KHZ;

[0038] 2) Set the constant temperature water bath in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com