Method for extracting and preparing passion fruit flavor

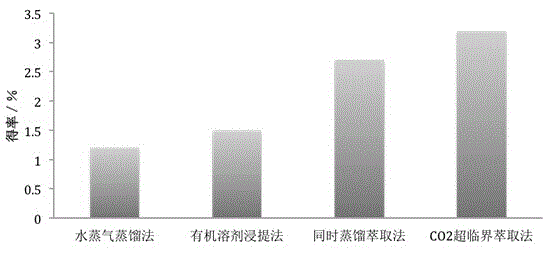

A passion fruit and spice technology, which is applied in the directions of essential oils/spice, fat production, etc., can solve problems such as no reports on the extraction technology of passion fruit spice, and achieve the effect of significant titrating effect, natural and pure aroma, and maintaining aroma characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for extracting passion fruit flavor, comprising the steps of:

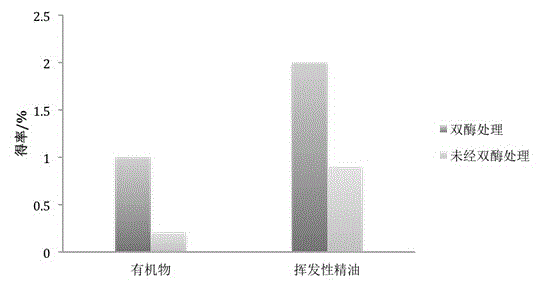

[0027] (1) Dual-enzyme hydrolysis

[0028] Passion fruit pulp is used as raw material, and pectinase and xylanase are used for dual enzyme treatment. The enzymatic hydrolysis conditions are: the amount of pectinase added is 0.001% of the weight of passion fruit pulp, and the amount of xylanase added is 0.001% of the weight of passion fruit pulp. 0.010%, the enzymatic hydrolysis temperature is 30°C, the enzymatic hydrolysis pH is 4, and the enzymatic hydrolysis time is 25 minutes;

[0029] (2) Extraction of organic substances by ionic liquid

[0030] The ionic liquid extraction was performed on the enzymatically hydrolyzed passion fruit pulp. The extraction conditions were as follows: the amount of the two ionic liquids added was 3mg / 50ml passion fruit pulp enzymatic hydrolyzate, the extraction time was 30min, the extraction pH was 6, and the extraction temperature was 30°C. Filter to ...

Embodiment 2

[0036] A preparation method for extracting passion fruit flavor, comprising the steps of:

[0037] (1) Dual-enzyme hydrolysis

[0038] Passion fruit pulp is used as raw material, and pectinase and xylanase are used for double enzyme treatment. The enzymatic hydrolysis conditions are: the amount of pectinase added is 0.016% of the weight of passion fruit pulp, and the amount of xylanase added is 0.016% of the weight of passion fruit pulp. 0.090%, the enzymatic hydrolysis temperature is 60°C, the enzymatic hydrolysis pH is 8, and the enzymatic hydrolysis time is 65min;

[0039] (2) Extraction of organic substances by ionic liquid

[0040]The ionic liquid extraction was performed on the enzymatically hydrolyzed passion fruit pulp. The extraction conditions were as follows: the amount of the two ionic liquids added was 8mg / 50ml passion fruit pulp enzymatic hydrolyzate, the extraction time was 120min, the extraction pH was 10, and the extraction temperature was 60°C. Filter to ob...

Embodiment 3

[0046] A preparation method for extracting passion fruit flavor, comprising the steps of:

[0047] (1) Dual-enzyme hydrolysis

[0048] Passion fruit pulp is used as raw material, and pectinase and xylanase are used for double enzyme treatment. The enzymatic hydrolysis conditions are as follows: the amount of pectinase added is 0.008% of the weight of passion fruit pulp, and the amount of xylanase added is 0.008% of the weight of passion fruit pulp. 0.050%, the enzymatic hydrolysis temperature is 45°C, the enzymatic hydrolysis pH is 6, and the enzymatic hydrolysis time is 45min;

[0049] (2) Extraction of organic substances by ionic liquid

[0050] The enzymatically hydrolyzed passion fruit pulp was extracted with ionic liquid. The extraction conditions were as follows: the amount of the two ionic liquids added was 6mg / 50ml passion fruit pulp enzymatic hydrolyzate, the extraction time was 75min, the extraction pH was 8, and the extraction temperature was 45°C. Filter to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com