A kind of pesticide residue scavenger and preparation method thereof

A pesticide residue and scavenger technology, which is applied in the field of cleaning agents, can solve the problems of secondary hazards, human-to-object injuries, etc., and achieve the effects of high removal efficiency, low dosage, and high safety, health and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

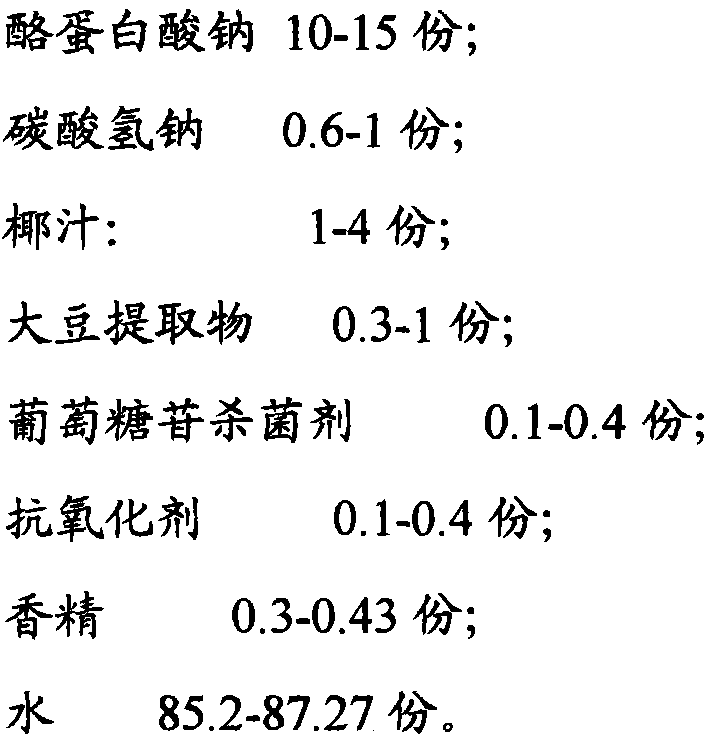

Method used

Image

Examples

Embodiment 1

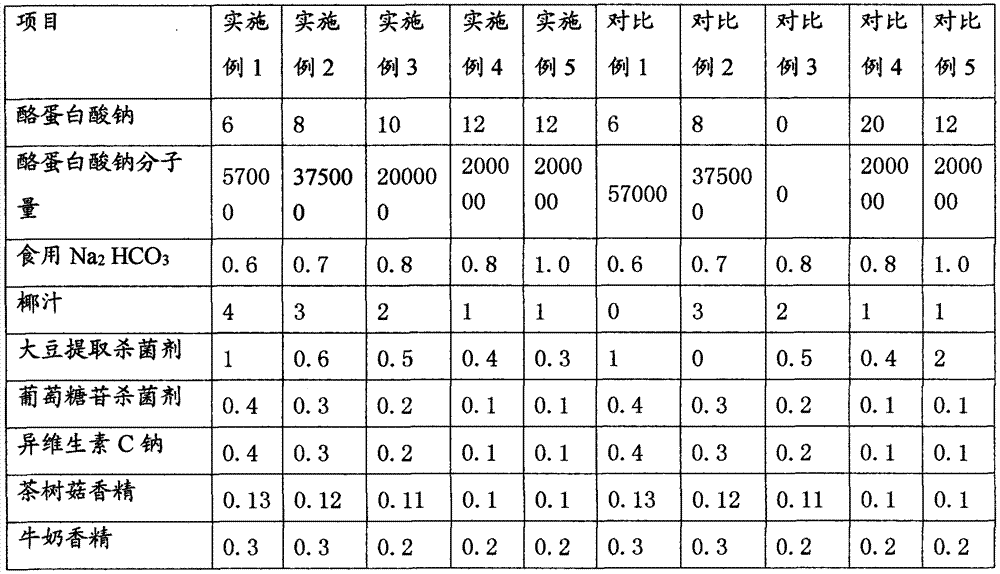

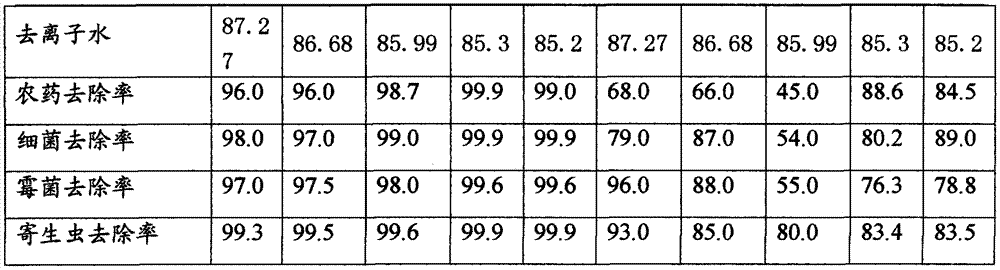

[0034] The following ingredients are taken in parts by weight as shown in Table 1 for subsequent use: sodium caseinate, edible sodium bicarbonate, coconut milk, soybean protein glue, glucoside fungicide, sodium isocitamin C, essence and water, wherein the caseinate The molecular weight of sodium is also shown in Table 1.

[0035] 1) Take 90% of the water and place it in a reaction kettle, add sodium caseinate and edible sodium bicarbonate, and wait until they are completely dissolved;

[0036] 2) Under the stirring condition of 30 rpm, slowly add soybean protein glue and glucoside fungicide until the solution is gelatinous;

[0037] 3) Add coconut milk and isovitamin C sodium, and stir the mixture at a speed of 30 rpm. The coconut milk used is prepared by mixing coconut milk powder and water evenly, and drying the fresh coconut milk in an anaerobic environment. Mix 10g of coconut milk powder with 90g of water to make coconut milk;

[0038] 4) Add essence and stir the mixture...

Embodiment 2

[0042] The following ingredients are taken according to the parts by weight shown in Table 1 for subsequent use: sodium caseinate, edible sodium bicarbonate, coconut milk, soybean protein glue, glucoside fungicide, sodium isovitamin C, essence and water.

[0043] 1) Take 50% of the water and place it in a reaction kettle, add sodium caseinate and edible sodium bicarbonate, and wait until it is completely dissolved;

[0044] 2) Under the stirring condition of 300 rpm, slowly add soybean protein glue and glucoside fungicide until the solution is gelatinous;

[0045] 3) Add coconut milk and isovitamin C sodium, and stir the mixture at a speed of 300 rpm. The coconut milk used is prepared by mixing coconut milk powder and water evenly. Take fresh coconut milk and dry it under anaerobic environment. Mix 35g of coconut milk powder with 65g of water to make coconut milk;

[0046] 4) Add essence and stir the mixture at a speed of 300 rpm;

[0047] 5) Add the remaining 50% of water a...

Embodiment 3

[0050] The following ingredients are taken according to the parts by weight shown in Table 1 for subsequent use: sodium caseinate, edible sodium bicarbonate, coconut milk, soybean protein glue, glucoside fungicide, sodium isovitamin C, essence and water.

[0051] 1) Take 70% of the water and place it in a reaction kettle, add sodium caseinate and edible sodium bicarbonate, and wait until it is completely dissolved;

[0052] 2) Under the stirring condition of 100 rpm, slowly add soybean protein glue and glucoside fungicide until the solution is gelatinous;

[0053] 3) Add coconut milk and isovitamin C sodium, and stir the mixture at a speed of 100 rpm. The coconut milk used is prepared by mixing coconut milk powder and water evenly, and drying the fresh coconut milk in an oxygen-free environment Mix 20g of coconut milk powder with 80g of water to make coconut milk;

[0054] 4) Add essence and stir the mixture at a speed of 100 rpm;

[0055] 5) Add the remaining 30% of water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com