Spirulina cell-wall breaking shearing device

A shearing device, spirulina technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve the problems of low wall breaking efficiency, secondary pollution, and high power consumption of spirulina cells, reaching Improve the cutting effect, facilitate assembly and disassembly, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

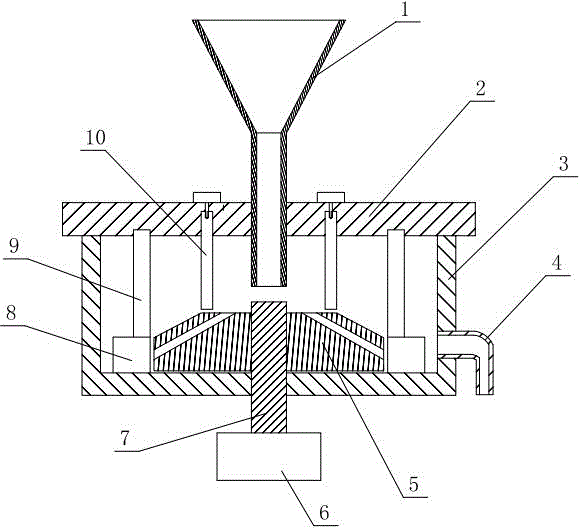

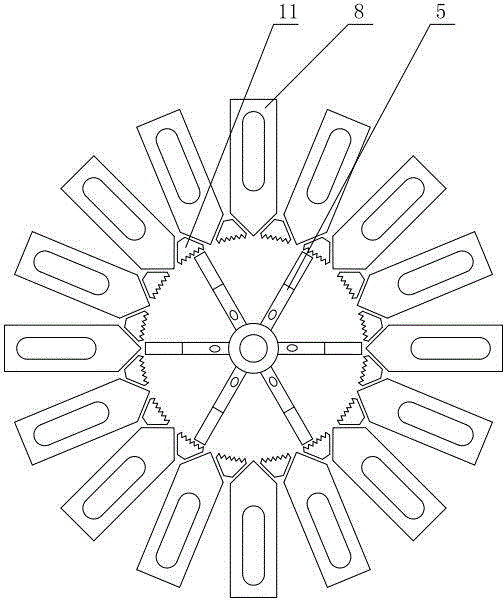

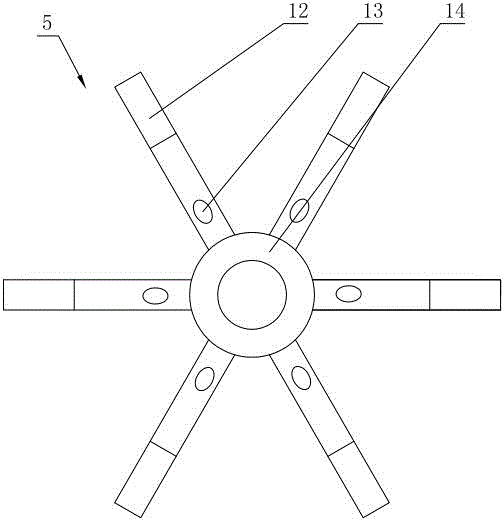

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the spirulina cell wall-breaking shearing device of the present embodiment includes a shearing chamber 3, the top of the shearing chamber 3 is fixed with a loam cake disc 2 by bolts, and the chassis of the shearing chamber 3 is sealed by a drive shaft 7 The rotor shearing impeller 5 is installed, the driving shaft 7 passes through the chassis of the shearing chamber 3 and is connected to the motor 6, and the driving shaft 7 is sealed and connected with the opening of the chassis of the shearing chamber 3; the circumferential direction of the chassis of the shearing chamber 3 is evenly spaced A plurality of stator blades 8 are installed, and the heads of the stator blades 8 are provided with symmetrical blade surfaces 16, and the tops of the two blade su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com