Method for conducting partial heat treatment on martensitic precipitated hardening stainless steel after repair welding

A technology of local heat treatment and precipitation hardening, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of difficult to control heating temperature and poor temperature uniformity, achieve reliable calibration results, simple methods, and ensure heating uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the implementation process of the inventive method in detail below in conjunction with an experimental example:

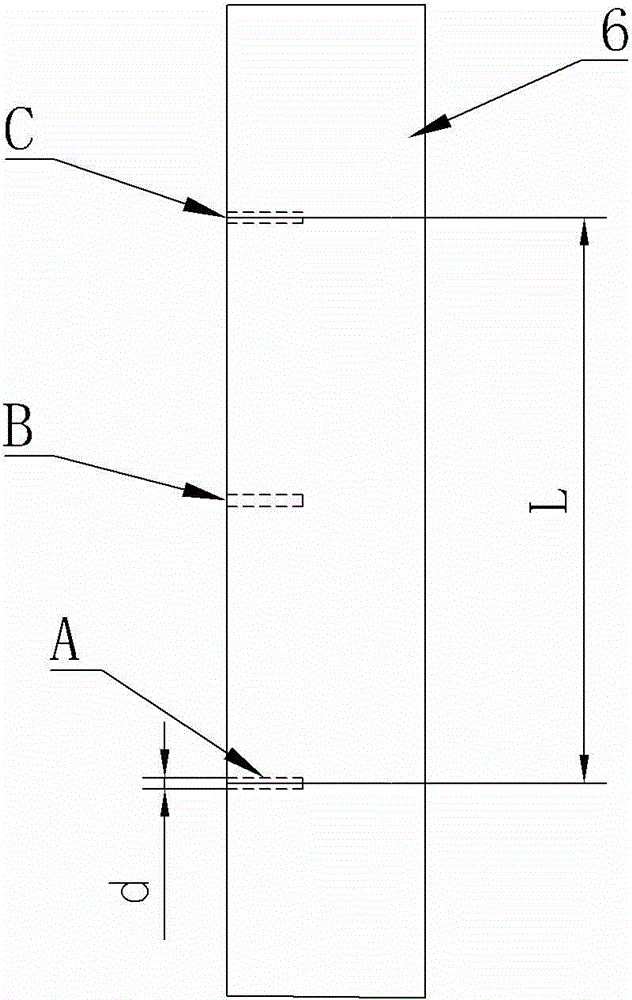

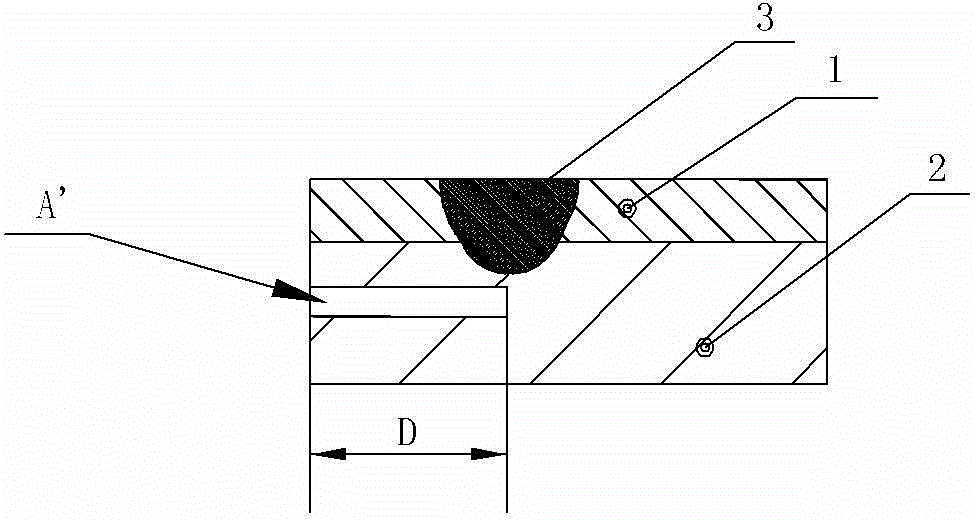

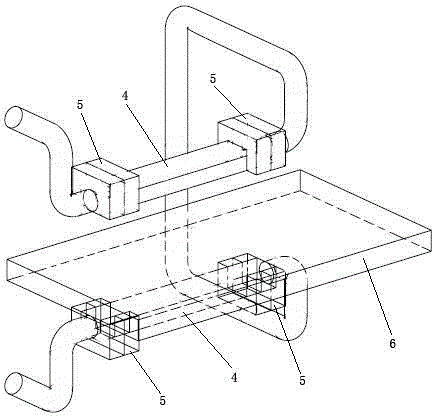

[0020] For a part whose material is 0Cr13Ni8Mo2Al, the maximum allowable length L of repair welding is 50 mm. If the hardness of the heat-affected zone decreases after defect repair welding, the heat-affected zone (see figure 1 ) for local heat treatment, the local heat treatment process is set at 530±5°C and the holding time is 2 hours. figure 1 Among them, 1 is the surfacing layer, 2 is the base metal, and 3 is the repair welding seam;

[0021] (1) Prepare the calibration part: use the same material as the part to prepare the calibration part 6, and the calibration part should undergo the same heat treatment and machining treatment as the part to ensure the same material state, and drill three test holes on one side of the calibration part , respectively test hole A, test hole B and test hole C, see figure 2 , the positions of the three test ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com