A trolley-type gas heat treatment furnace temperature control system and temperature control method

A heat treatment furnace and temperature control system technology, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of large temperature fluctuations in the temperature control area, reduced service life of equipment, uneven temperature changes, etc., to achieve the benefit of remote The effects of management, improving work efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be completed below in conjunction with the accompanying drawings, taking a trolley-type gas heat treatment furnace with a size of 14m×6m×5m (length, width and height) as an example. described.

[0030] Among them, the loading capacity of the trolley-type gas-fired heat treatment furnace in this embodiment is ≤540t, the furnace body is a cuboid with fixed steel structure, and a liftable furnace door is provided on one side of the opening in the length direction.

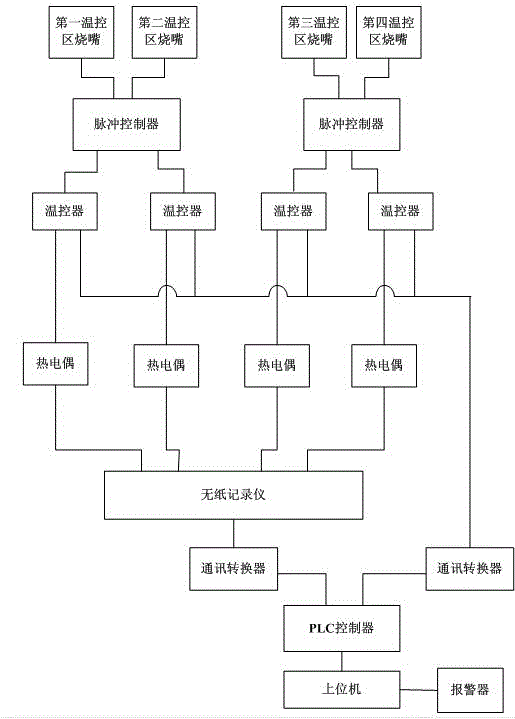

[0031] figure 1 The shown temperature control system of a trolley-type gas heat treatment furnace includes four temperature control zones distributed along the length direction of the furnace body, the first temperature control zone, the second temperature control zone, the third temperature control zone and the fourth temperature control zone. temperature control area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com