Operating mechanism of bucket-wheel dredger

An operating mechanism and dredger technology, applied to mechanically driven excavators/dredgers, etc., can solve the problems of uncountable workload and equipment loss, unrealizable efficiency statistics, unavailable statistics of dredging measurement, etc., to achieve expanded operation The scope, improve work efficiency, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

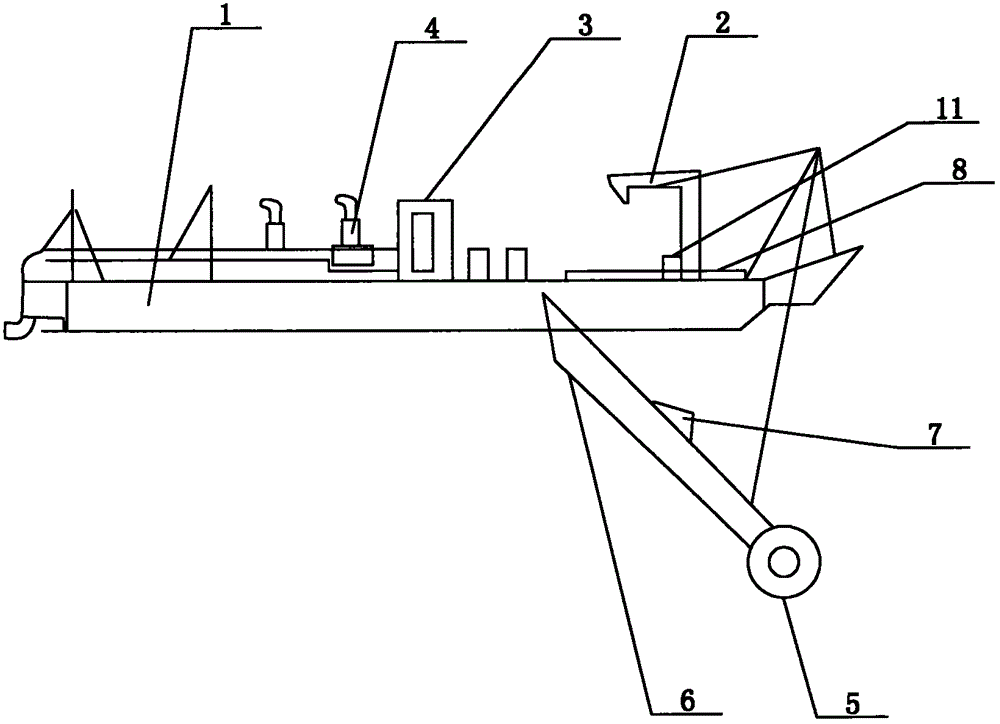

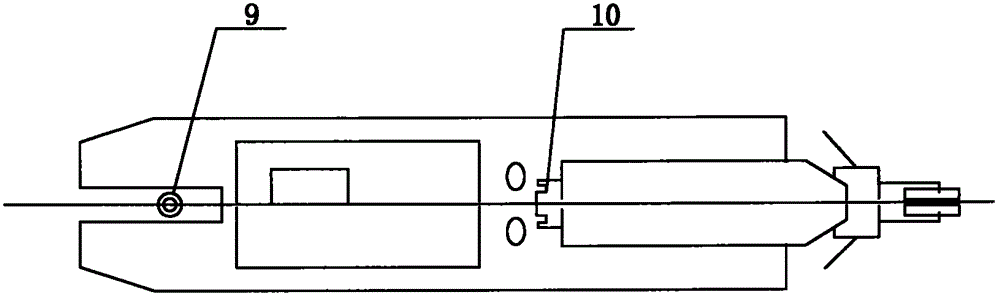

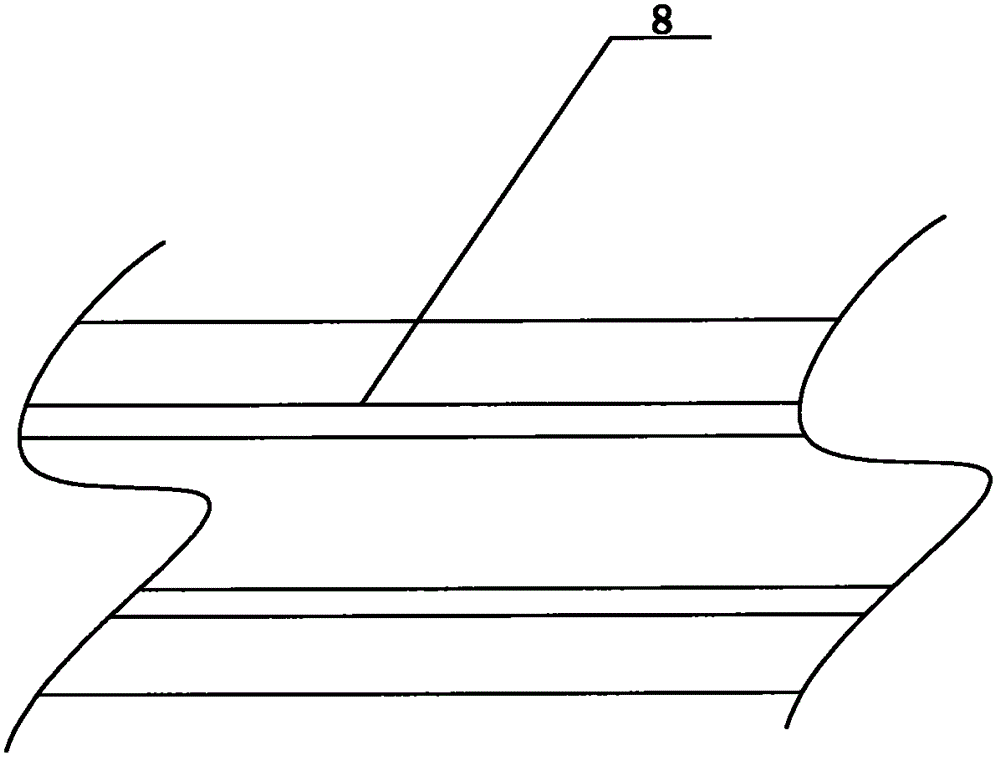

[0020] see Figure 1 to Figure 4 , the specific embodiment adopts the following technical solutions: including hull 1, bow crane 2, cockpit 3, production meter 4, bucket wheel 5, bucket bridge frame 6, underwater mud pump 7, slideway 8, positioning column trolley 9, Pivot gear box 10, block 11; bow crane 2 is arranged on one end of hull 1, and the bottom of bow crane 2 is movably arranged in slideway 8, is provided with stopper 11 in slideway 8, and the other end of hull 1 is provided with The positioning column trolley 9 is provided with a cockpit 3 on the hull 1, and the production meter 4 is arranged on one side of the cockpit 3, and a bucket bridge frame 6 is provided under the other side of the cockpit 3, and a bucket bridge frame 6 is provided at the end of the bucket bridge frame 6. The wheel 5 and the bucket bridge frame 6 are provided with an underwater mud pump 7, and the bucket wheel 5 is provided with an environmental protection reamer 8, and one end of the bucket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com