A logging-while-drilling acoustic logging method and device based on dual-source flyback technology

A kind of technology while drilling, which is applied in the field of sonic logging method and device while drilling, which can solve the problems of drill collar wave interference, etc., and achieve the effects of reducing maintenance costs, avoiding groove design, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

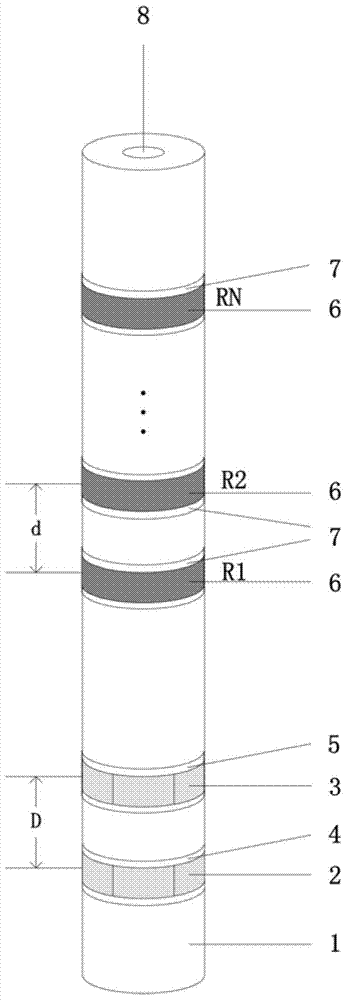

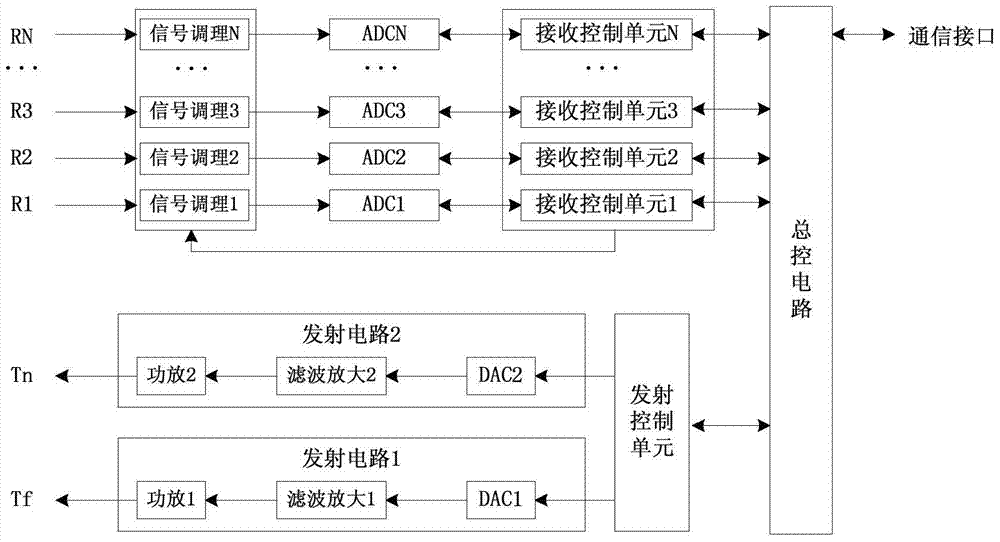

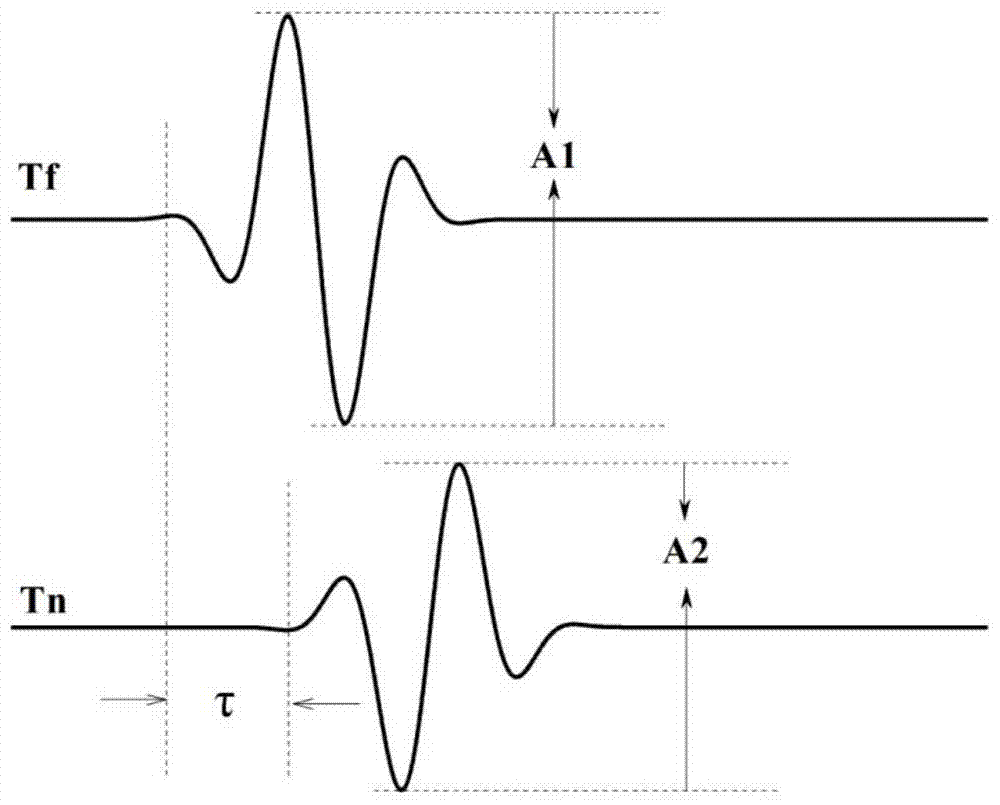

[0037] The sonic logging while drilling tool based on dual-source flyback technology such as figure 1 shown. It mainly includes the sound system part and the circuit part (both are embedded in the drill collar). Acoustic part such as figure 1 As shown, it consists of a dual-source transmitting and receiving array. In the figure 1 is the drill collar, 2 and 3 are the remote transmitters T f , near the transmitter T n , are two monopole piezoelectric transducers with the same working performance, which can emit sound waves to the formation under the excitation of the high voltage of the transmitting circuit. 6 is a monopole receiving array composed of N piezoelectric ceramic sensors, which can convert acoustic signals into electrical signals by using the piezoelectric effect of piezoelectric ceramics. The number of receivers N is usually 4 to 16 , 7 is the receiver protection cover, and the main function is to protect the receiving transducer and sound transmission; 8 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com