Concentric straight-axis power machine

A power machine, straight shaft technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of complex engine structure, large energy loss, high cost, omitting crankshaft and connecting rod parts, simplifying complex structures , the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

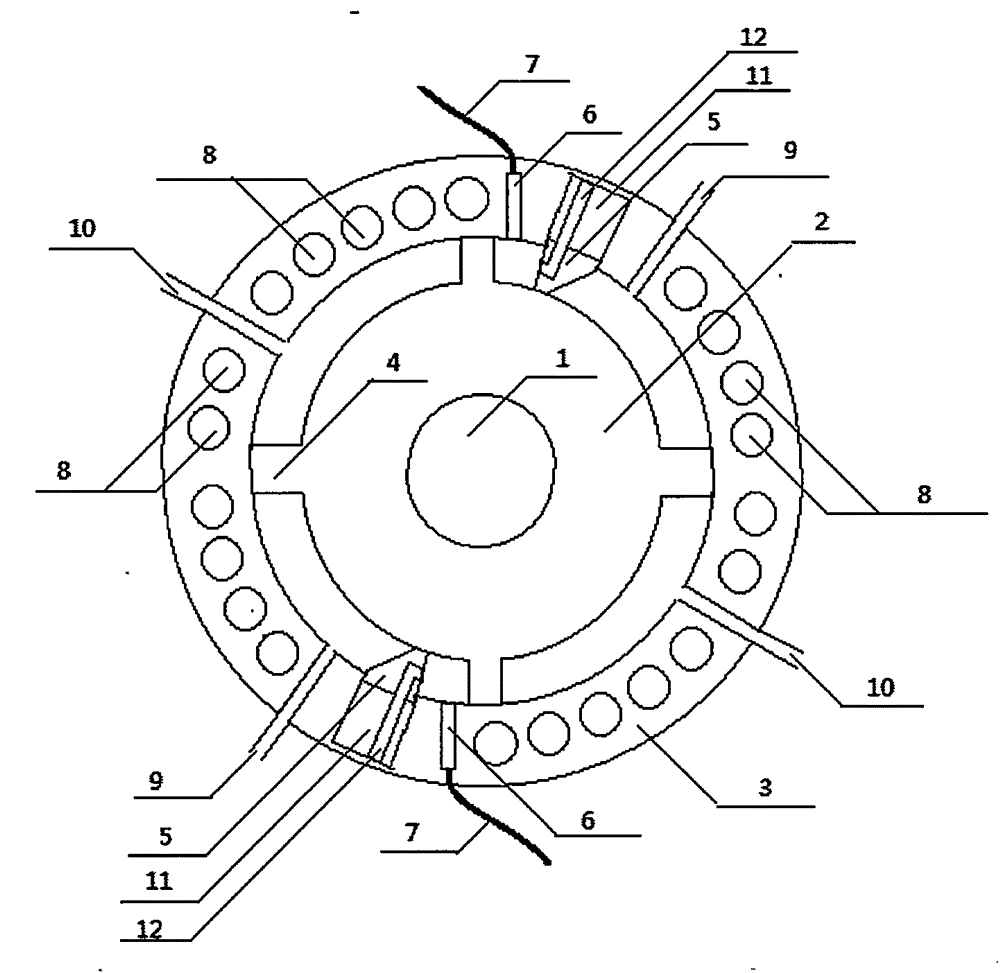

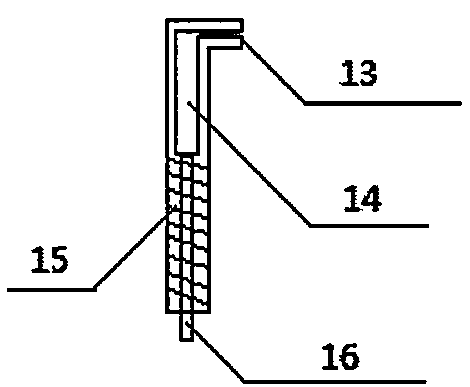

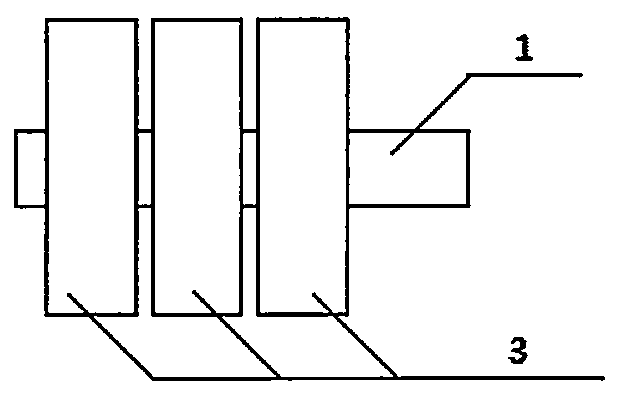

[0014] The concentric direct shaft power machine is made by precision machining. The parts with high precision requirements are mainly reflected in the precision of the rotor 2, the stator shell 3 and the rotor fixed teeth 4, and also include the precision requirements of the sliding surface of the sealing pin 5. The rotating shaft 1 and the rotor 2 are rigidly connected as one, and the rotation of the rotor 2 is transmitted outward through the rotating shaft. Four equally spaced teeth 4 are precisely machined on the stator 2. There are an air intake pipe 9 and an exhaust pipe 10 on the stator shell 3. , spark plug 6, sealing pin 5 and telescopic compartment 11 of sealing pin, there is a single-valve fuel supply mechanism 12 inside the seal pin 5, and there are fuel nozzle 13, oil pump chamber 14, spring 15 and oil pipe inside the single-valve fuel supply mechanism 12 16. The space corresponding to the spark plug 6 is the deflagration chamber; the sealing pin 5 moves up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com