Damping-force-variable shock absorption assembly

A damping force, variable technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem that the comfort and reliability cannot be well coordinated, and cannot meet the different needs of different road conditions, motorcycles, etc. The car cannot adapt to the use environment and other problems, so as to achieve the effect of simplifying the locking structure itself, strong replaceability, and simple and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

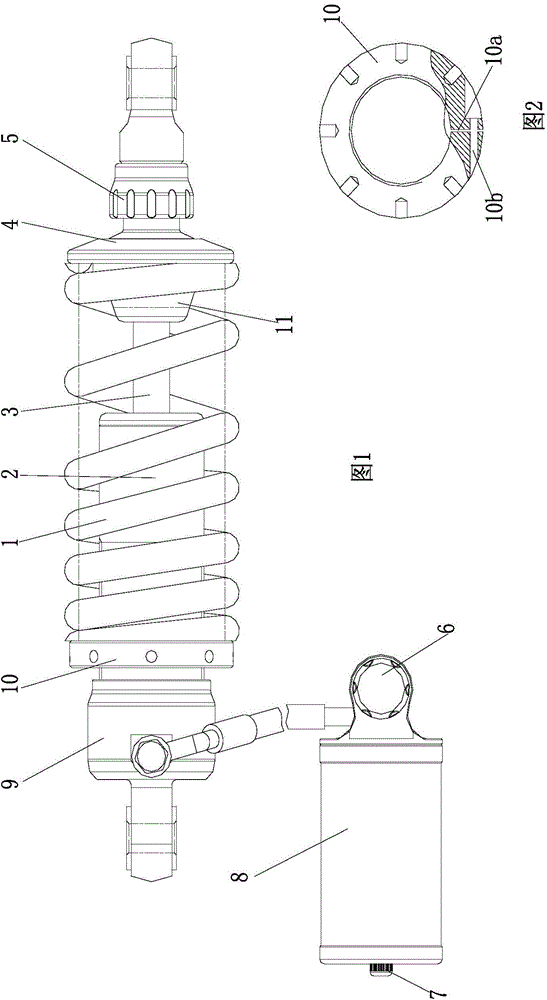

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the lock nut structure, as shown in the figure: the damping assembly with variable damping force in this embodiment includes a damping spring 1 and a damper assembly, and the damper assembly includes a damping cylinder 2 and a piston assembly, and the piston The assembly certainly includes a piston and a piston rod 3; the shock absorber is provided with a restoration damping force adjustment device, and the damping force adjustment device at least includes a first damping force adjustment member for adjusting the compression length of the shock absorber spring; through the compression length The adjustment realizes the adjustment of the restoration damping force, so as to facilitate the adjustment according to different driving conditions, and the adjustment scale can be set, so as to have the reference function of adjustment.

[0020] In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com