Valve element of proportional electromagnetic valve and proportional electromagnetic valve with valve element

A proportional solenoid valve, valve core technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of dynamic performance impact, thin wall easily deformed, difficult processing, etc., to reduce eccentric wear, liquid flow direction Optimized, easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

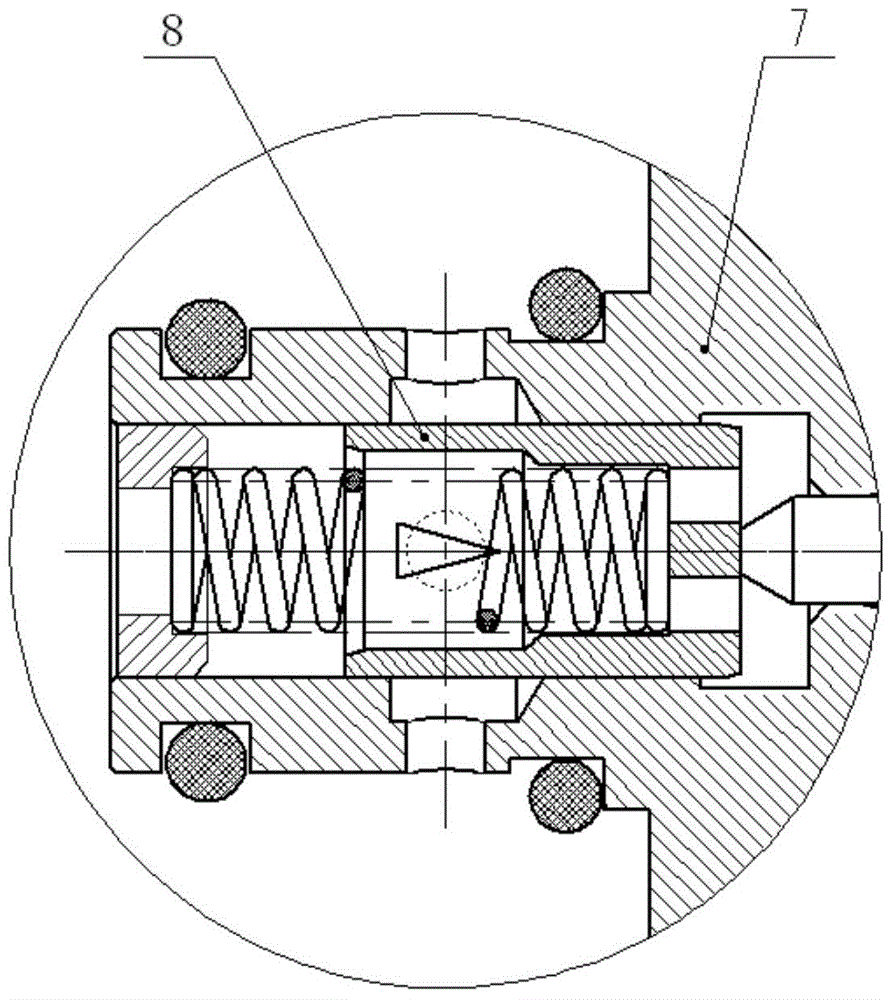

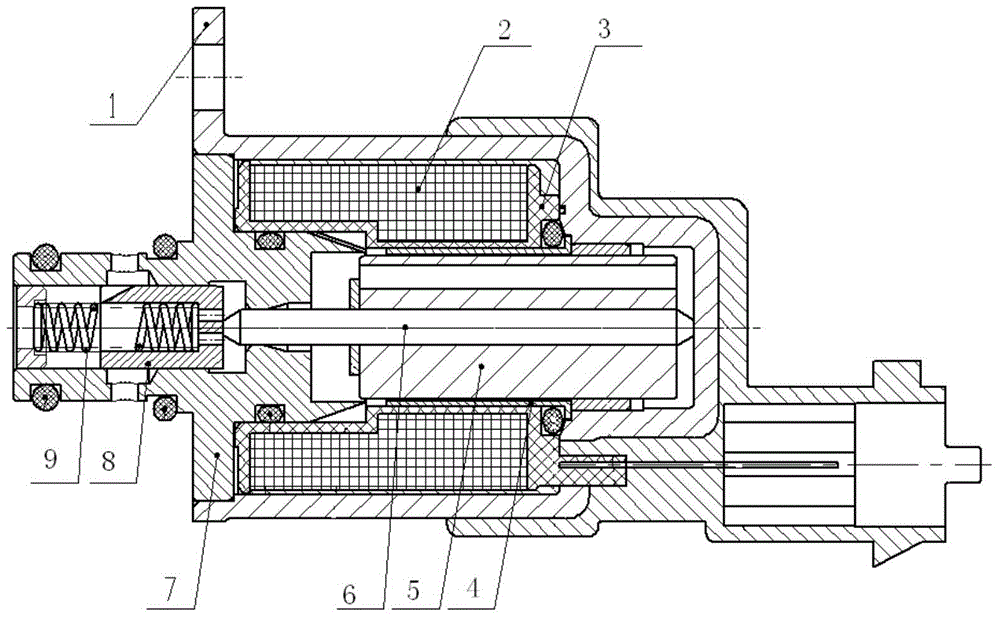

[0024] Embodiment one, with reference to the attached figure 2 As shown, the proportional solenoid valve of the present invention includes a housing 1, an electromagnetic coil 2, a skeleton 3 for winding the electromagnetic coil 2, a guide sleeve 4 inside the skeleton 3, a moving iron core 5 inside the guide sleeve 4, an interference The push rod 6 installed on the moving iron core 5, the static iron valve seat 7 assembled on the front end of the solenoid valve, the valve core 8 and the adjustment spring 9 located in the inner hole of the static iron valve seat 7. The tail of the proportional solenoid valve housing 1 is encapsulated by injection molding, and the head of the push rod 6 bears against the rear end plane of the spool 8 to push the spool 8 forward. The adjustment spring 9 is located at the other end of the spool 8 and can push the spool 8 to move backward. The inner wall of the static iron valve seat 7 is provided with an inner annular groove communicating with t...

Embodiment 2

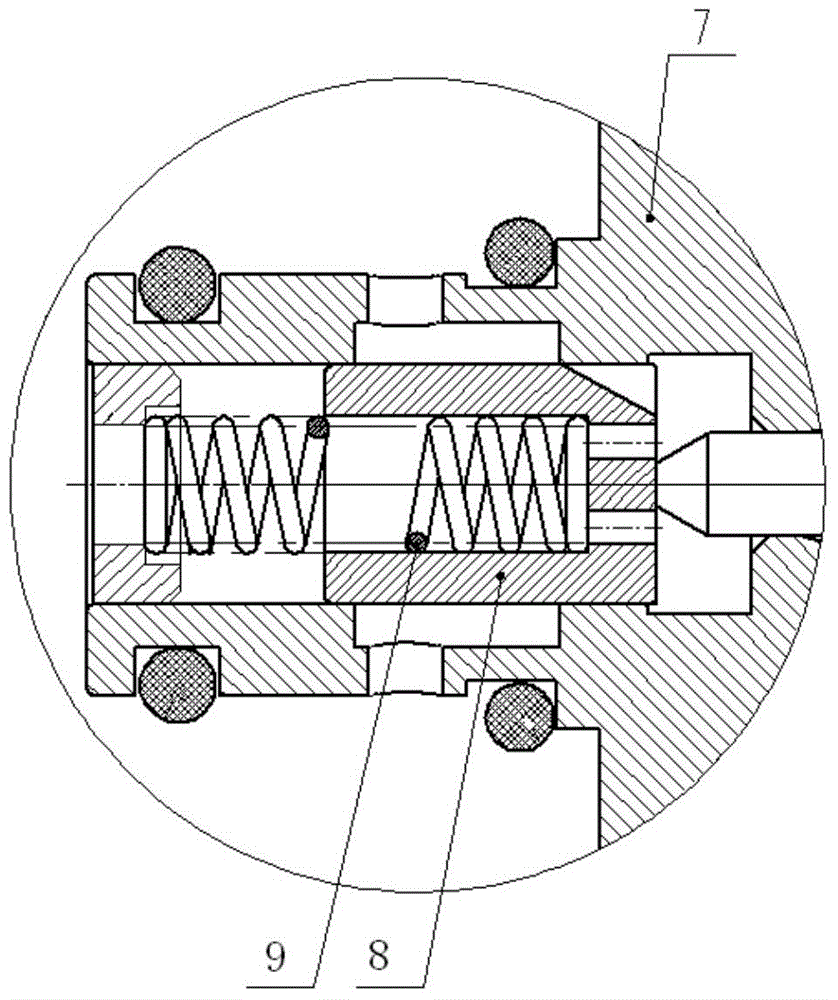

[0028] Embodiment two, referring to the attached image 3 As shown, the difference between this embodiment and the first embodiment is that the spool described in the first embodiment belongs to the proportional solenoid valve in the form of power-off normally open, while the spool in this embodiment belongs to the form of power-off normally closed Proportional solenoid valve spool, that is, when the current is zero, the flow characteristic of the solenoid valve is 0. The specific structure of the spool in this embodiment is that a plurality of flow regulating grooves are uniformly arranged on the outer circumference of the rear end of the spool 8, such as 3 evenly distributed flow regulating grooves or 2 symmetrically distributed flow regulating grooves. The rest of this embodiment is the same as the first embodiment, and will not be repeated here.

Embodiment 3

[0029] Embodiment three, with reference to the attached Figure 4 As shown, the difference between this embodiment and the first embodiment is that the valve core 8 is a cylindrical valve core without an inner cavity, and the adjustment spring 9 bears against the front end of the valve core 8 . The spool 8 is provided with more than one oil hole along the axial direction, which can balance the hydraulic pressure at both ends of the spool 8 and reduce the blockage during movement. The rest of this embodiment is the same as the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com