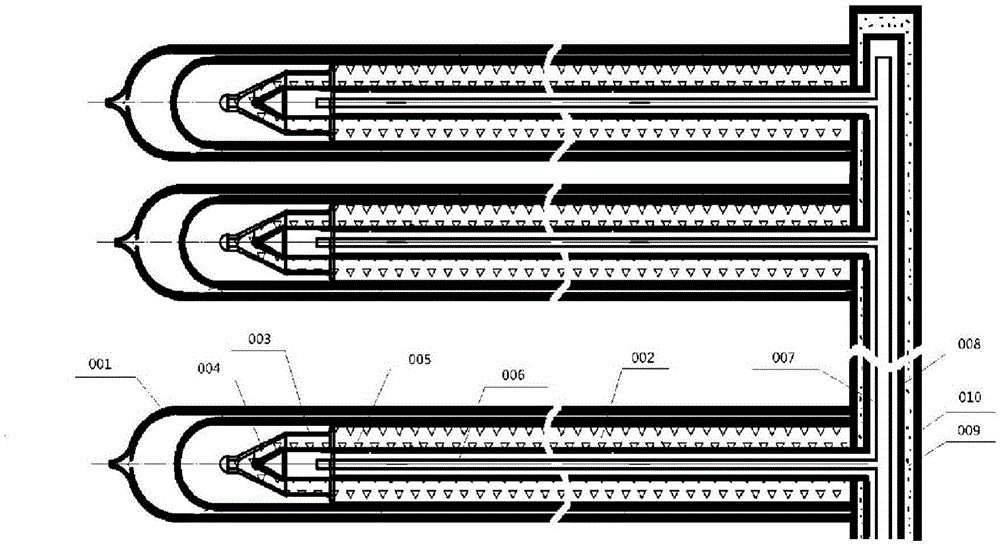

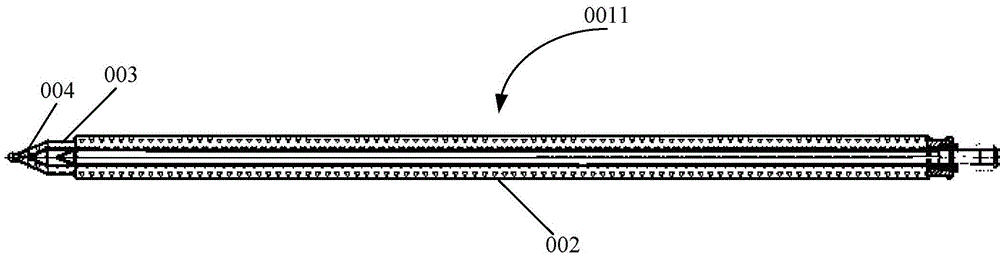

Solar thermal storage tube and processing method thereof

A processing method and heat storage tube technology, which is applied in the field of solar heat storage, can solve problems such as insufficient structural strength and pressure bearing capacity of heat storage tubes and heat conduction tubes, affecting product heat conversion efficiency and user experience, structural safety performance, and service life. , to achieve the effect of simple structure, simple processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

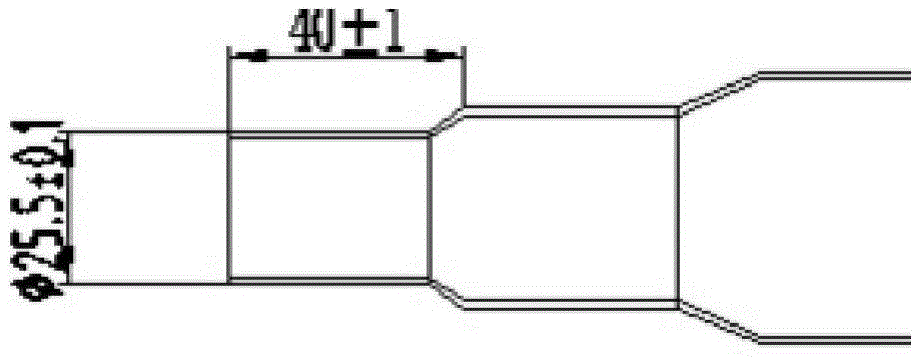

[0046] A method for processing a heat storage tube of a solar heat storage tube, comprising the following steps:

[0047] Step 1: Through the automatic pipe end forming machine, send the hollow aluminum casting pipe with an outer diameter of φ42 into the automatic pipe end forming machine with a mold of φ38, and the entry depth is 70mm, which takes 5 seconds.

[0048] During processing, manually fix one end of the heat storage tube on the machine, start the button, and then the machine automatically pushes the aluminum casting pipe into the processing end under the corresponding mold and settings for processing. In a preferred embodiment of the present invention, the automatic pipe end forming machine used is the HP-GD automatic pipe end forming machine of Hewlett-Packard Machinery.

[0049] Step 2: Put the cast aluminum pipe piece processed in step 1 into the automatic pipe end forming machine with a mold of φ35, and the depth of entry is 70mm, which takes 5 seconds.

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com