Method for in-situ processing and structural characterization of composite inclusion in steel

A technology of composite inclusions and inclusions, which is applied in the preparation of test samples, material analysis using radiation diffraction, material analysis using secondary emission measurement, etc., can solve the problem that in-situ observation of the microstructure of inclusions is difficult to achieve, etc. Achieve the effects of short sample preparation cycle, high processing efficiency and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the examples.

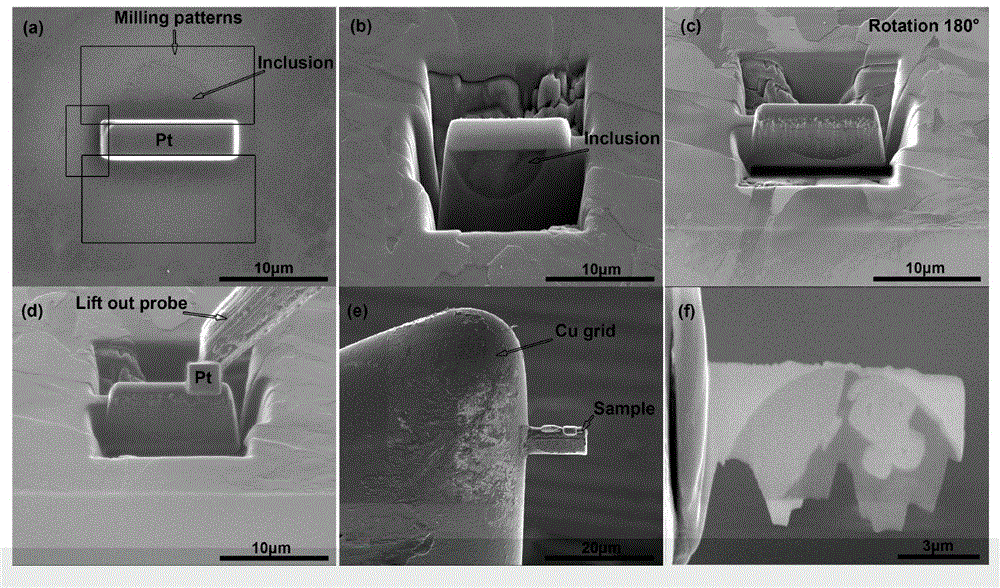

[0029] (1) Use the focused ion beam to precisely locate and in-situ prepare the TEM profile samples of the composite inclusions of interest. The specific steps are as follows:

[0030] ① Plating Pt, in figure 1 Select an area of interest on the inclusions selected in , try to include more information about the inclusions, and plate a strip-shaped Pt layer on the selected area, such as figure 1 (a) shown. The purpose of the Pt layer is to protect the sample during the subsequent ion beam processing.

[0031] ②For ion beam cutting, select the Rectangle mode and press figure 1 The three cutting frames shown in (a) were cut using high current. After that, the large current changes to a small current, and the Cleaning Cross Section mode is selected to refine the two surfaces of the sample so that the surface of the sample is as smooth as possible. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com