Microwave source phase noise test method and device based on microwave photon mixing technology

A microwave photon, phase noise technology, applied in the direction of noise figure or signal-to-noise ratio measurement, can solve the problems of reduced test accuracy, working bandwidth and test accuracy limitations, etc., to achieve large bandwidth, large dynamic range, and increased operating bandwidth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

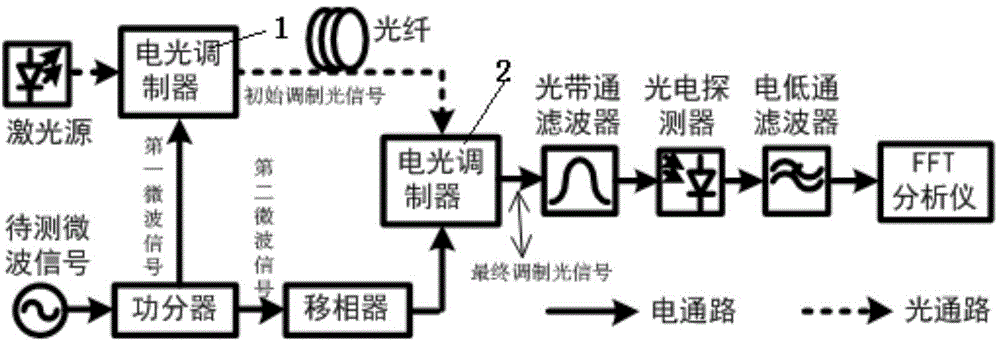

[0020] Microwave source phase noise test device based on microwave photon mixing technology, such as figure 1 As shown, it includes a microwave source, a microwave power divider, a microwave phase shifter, a laser source connected in sequence along the optical path, a first electro-optic modulator 1, an optical fiber, a second electro-optic modulator 2, an optical bandpass filter, and a photoelectric detector device, electric low-pass filter and FFT analyzer; the output end of the microwave source is connected with the input end of the microwave power splitter; the two output ends of the microwave power splitter: one of the output ends is connected with the first electro-optical modulation The drive signal input end of the device 1 is connected, and the other output end is connected with the input end of the microwave phase shifter; the output end of the microwave phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com