Grid polarizing device and method for manufacturing grid polarizing device

A technology for component manufacturing and grid polarization, applied in the field of polarizing components, can solve problems such as the decrease in extinction ratio, and achieve the effects of improved uniformity and easy microfabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Next, examples belonging to the above-mentioned embodiments will be described.

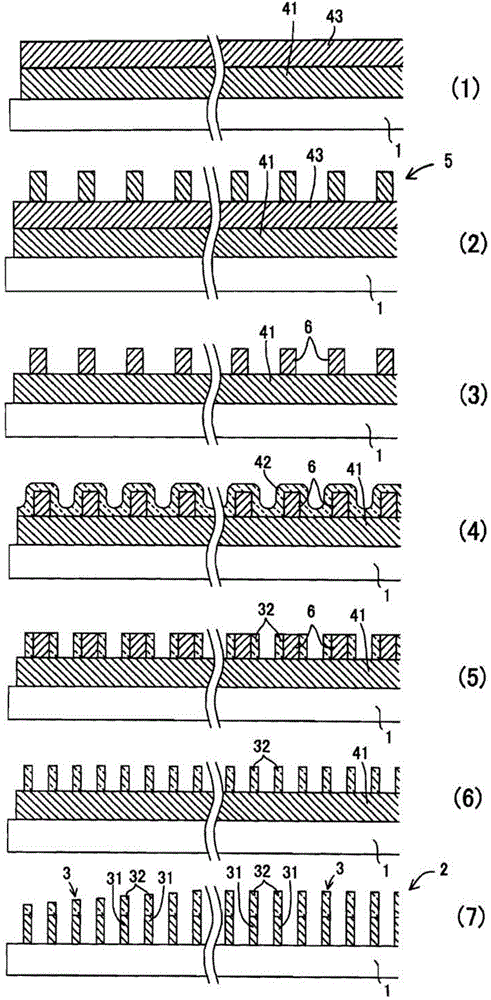

[0102] In the method for manufacturing a grid polarizing element in the embodiment, a silicon film having a thickness of 100 nm is formed as a first thin film on a transparent substrate made of synthetic quartz by a magnetron sputtering device. At this time, the temperature of the stage on which the transparent substrate was placed was room temperature, and argon gas was introduced into the chamber at a flow rate of 30 sccm as a process gas. In this state, a high frequency of 13.56 MHz was applied at 300 W to silicon as a target.

[0103] Argon gas is decomposed by the above-mentioned high frequency into a plasma state, and argon ions are generated. The generated argon ions collide with the negative potential silicon target while being accelerated, and knock out silicon from the target. The knocked-out silicon is deposited on a transparent substrate arranged to face the target to form a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com