Indoor poster and making method thereof

A production method and technology for advertising pictures, applied in the field of advertising pictures, can solve the problems of high construction difficulty, difficult to clean up, easy anti-sticking of ink to the back, etc., and achieve the effect of safe and convenient pasting and replacement, simple and feasible process, and reliable picture pasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

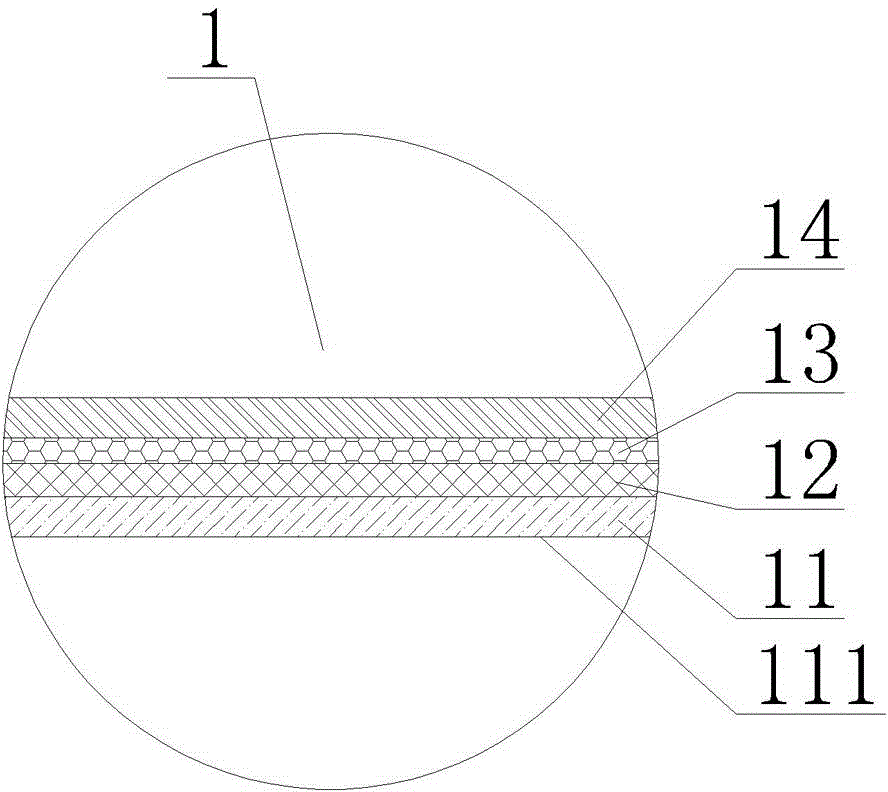

[0047] Such as figure 2 Shown, the making method of interior poster of the present invention comprises the steps:

[0048] First, make a color-developing background layer 14;

[0049] Then, the transparent adhesive layer 13 is coated on the color-developing background layer 14;

[0050] Then, on the transparent film 11, the pattern layer 12 is made by inkjet printing or silk screen printing or printing or hot stamping;

[0051] Finally, the color-developing background layer 14 is pasted on the surface of the transparent film 11 provided with the pattern layer 12 through the transparent adhesive layer 13, and after cutting, the production of the inner poster is completed.

Embodiment 2

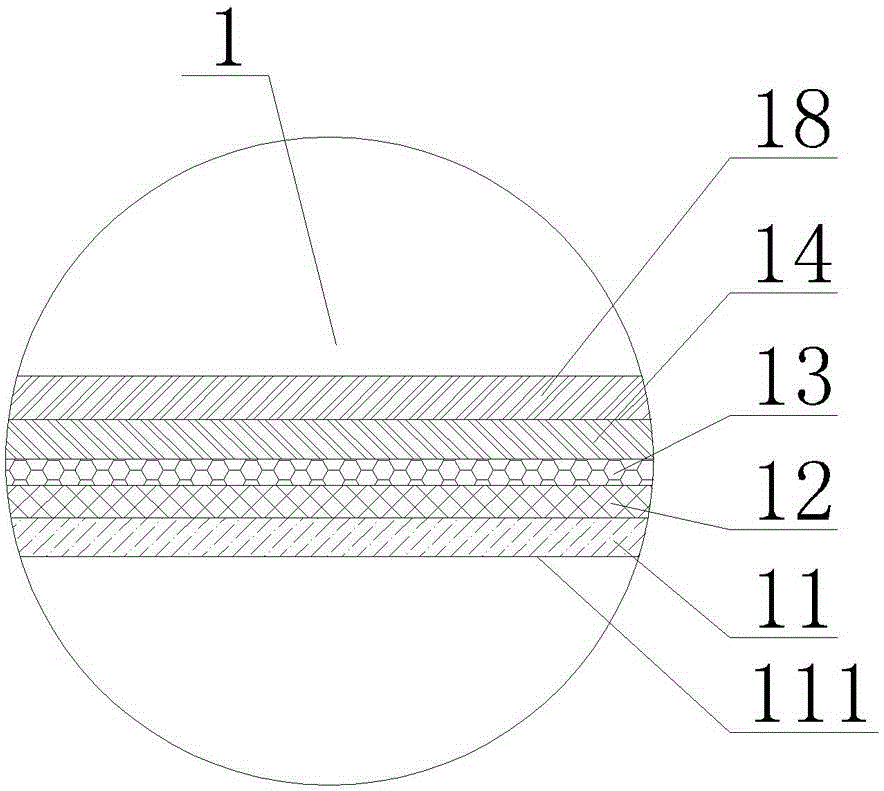

[0053] Such as image 3 Shown, the making method of interior poster of the present invention comprises the steps:

[0054] First, make a color-developing background layer 14;

[0055] Then, a light-shielding layer 18 is set on one side of the color-developing background layer 14;

[0056] Then, on the other side of the color-developing background layer 14, the transparent adhesive layer 13 is coated;

[0057] Then, on the transparent film 11, the pattern layer 12 is made by inkjet printing or silk screen printing or printing or hot stamping;

[0058] Finally, the color-developing background layer 14 is pasted on the surface of the transparent film 11 provided with the pattern layer 12 through the transparent adhesive layer 13, and after cutting, the production of the inner poster is completed.

Embodiment 3

[0060] Such as Figure 4Shown, the making method of interior poster of the present invention comprises the steps:

[0061] First, make a color-developing background layer 14;

[0062] Then, a light-shielding layer 18 is set on one side of the color-developing background layer 14;

[0063] Then, the picture printing layer 20 is set on the light-shielding layer 18;

[0064] Then, on the other side of the color-developing background layer 14, the transparent adhesive layer 13 is coated;

[0065] Then, print the picture on the picture printing layer 20;

[0066] Then, on the transparent film 11, the pattern layer 12 is made by inkjet printing or silk screen printing or printing or hot stamping;

[0067] Finally, the color-developing background layer 14 is pasted on the surface of the transparent film 11 provided with the pattern layer 12 through the transparent adhesive layer 13, and after cutting, the production of the inner poster is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com