Method for manufacturing ultra-thin type touch switch

A technology of tact switch and manufacturing method, applied in electrical switches, electrical components, circuits, etc., can solve the problems of high manufacturing cost, increase of plastic nozzle material, obvious mold clamping pattern, etc., and achieve manufacturing cost and quality improvement. The effect of shortening cycle time and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

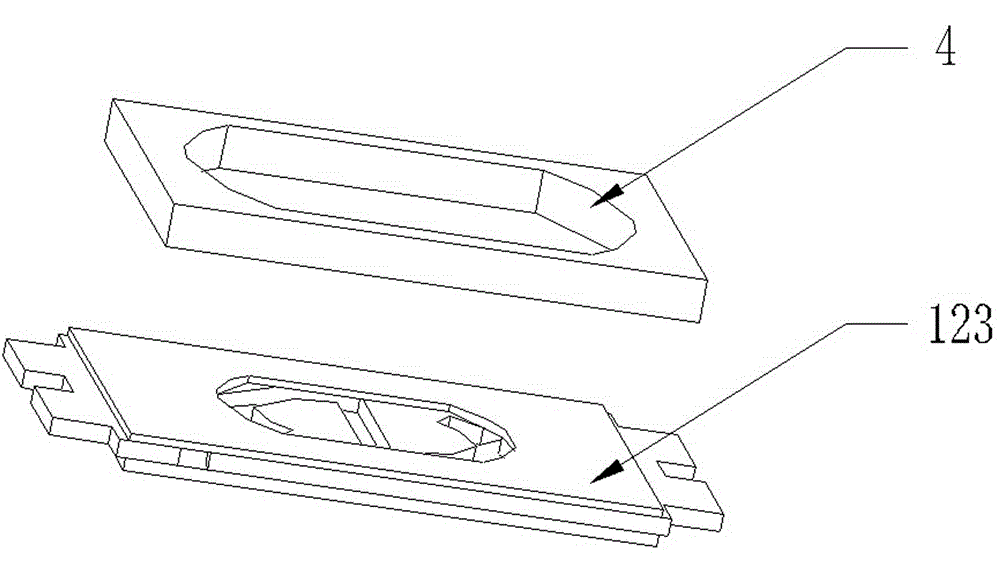

[0049] a. Firstly, the supplier is required to cut the PI film with a base film 1 of 2MIL into a fixed size, and make it into a coil or a sheet with a fixed shape, which is convenient for subsequent stamping and forming mold processing. It is also possible to ask the supplier to directly provide processed coils or sheets with fixed specifications. The side of the PI film that contacts the card must be coated with semi-cured high-temperature epoxy resin, and the surface is protected by a plastic film. Before removing the plastic film, it cannot If there is dust or impurities infiltrated, the PI film is stamped and made into a roll or sheet of the size and specification of the bottom film required by the switch for use.

[0050] b. Secondly, the supplier is required to cut the 1 / 2MIL PI film of the mask 3 into a fixed size, and make it into a coil or a sheet of a fixed shape, which is convenient for subsequent stamping and forming mold processing. Suppliers can also be require...

Embodiment 2

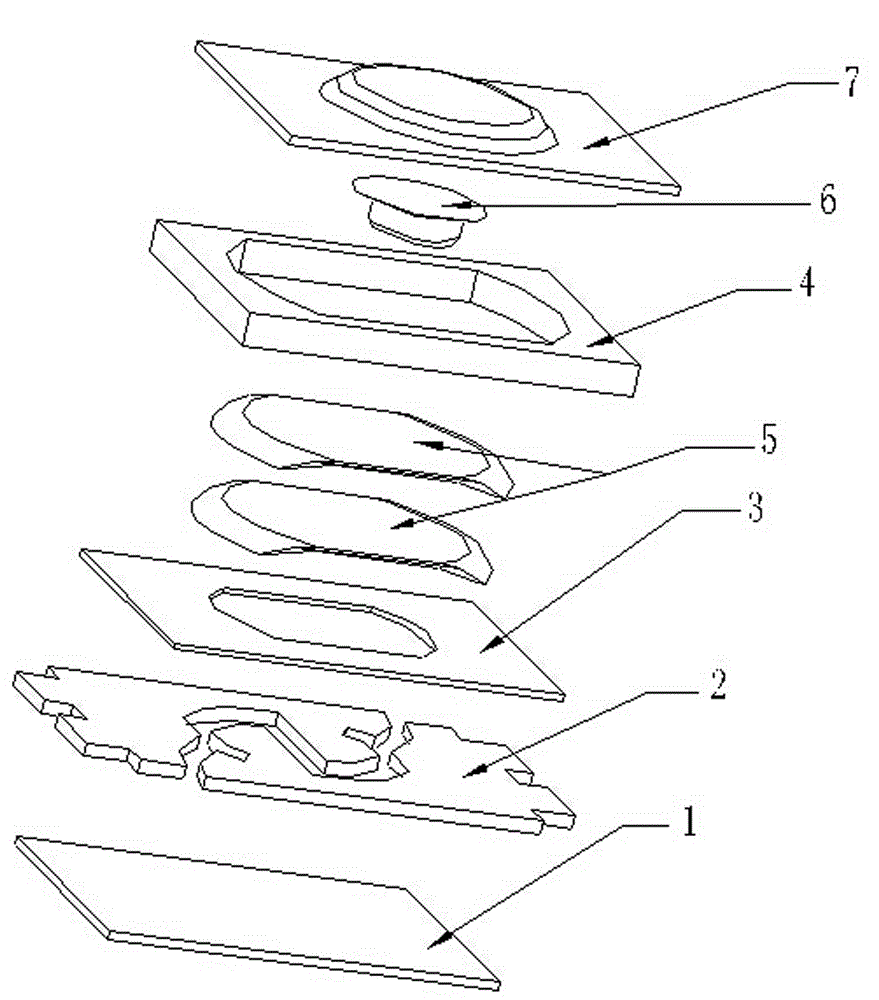

[0065] A method of manufacturing an ultra-thin tact switch, using hot pressing from bottom to top in order to heat press the base film, A / B PIN pin, mask, cavity, metal shrapnel, button and top film; wherein: the manufacturing method Proceed as follows:

[0066] 1) Material preparation:

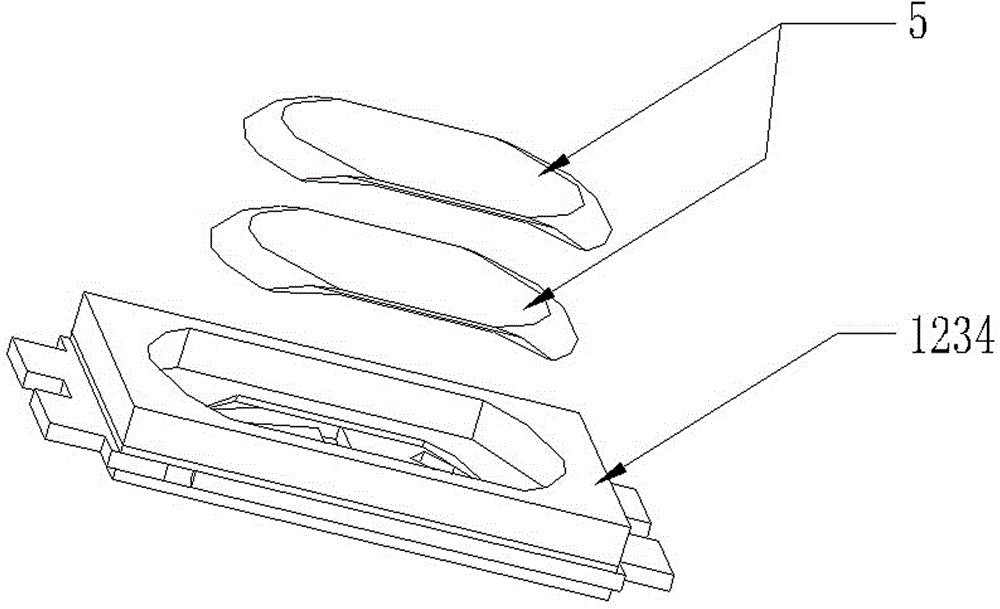

[0067] ① Cut the PI film with a base film of 2 MIL, the PI film with a surface mold of 1 / 2 MIL, and the PI film with a cavity of 7 MIL to a fixed size, make it into a coil or sheet, and stamp it into a mold for use;

[0068]② Cut the PI film with a top film of 2MIL into a fixed size, coat it with high-temperature epoxy resin, integrate the silicone button into the high-temperature epoxy resin to form a whole with the PI top film, and make it into a coil or a fixed-shaped plate for subsequent Stamping mold processing and production;

[0069] ③Punch the metal material into the sheet or wire of the A / B Pin structure required by the switch for use;

[0070] ④Silver-coated or silver-pressed or ...

Embodiment example 3

[0088] A method of manufacturing an ultra-thin tact switch, using hot pressing from bottom to top in order to heat press the base film, A / B PIN pin, mask, cavity, metal shrapnel, button and top film; wherein: the manufacturing method Proceed as follows:

[0089] 1) Material preparation:

[0090] ①Cut the PI film with a base film of 2MIL, the PI film with a surface mold of 1 / 2MIL, and the PI film with a cavity of 7MIL into a fixed size, make it into a coil or sheet, and stamp the mold for use;

[0091] ② Cut the PI film with a top film of 2MIL into a fixed size, coat it with high-temperature epoxy resin, integrate the silicone button into the high-temperature epoxy resin to form a whole with the PI top film, and make it into a coil or a fixed-shaped plate for subsequent Stamping mold processing and production;

[0092] ③Punch the metal material into the sheet or wire of the A / B Pin structure required by the switch for use;

[0093] ④Silver-coated or silver-pressed or silver-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com