Differential charge amplifier with high precision, low temperature drift and low offset

A charge amplifier, high-precision technology, used in differential amplifiers, charge amplifiers, amplifiers, etc., can solve the problems of large feedback resistance, large temperature drift and offset voltage of the charge amplifier, and interference, and achieve small temperature drift and high amplification accuracy. , the effect of small bias voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

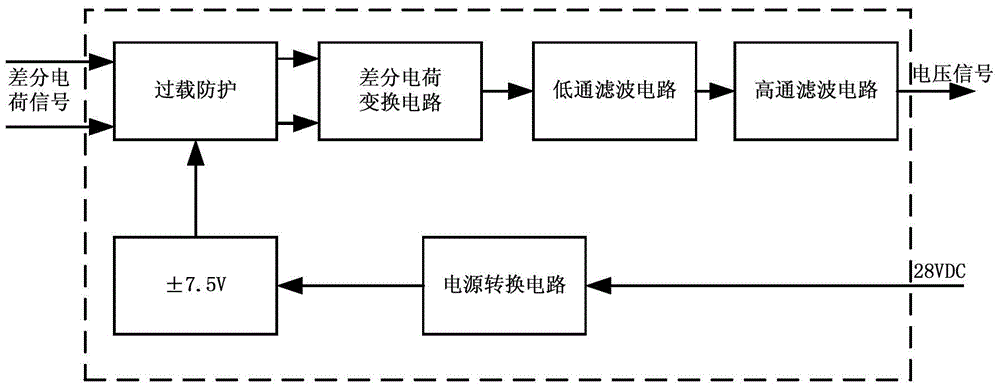

[0034] Such as figure 1 As shown, the differential high-precision low-temperature drift low-offset charge amplifier of the present invention includes an overload protection circuit, a differential charge conversion circuit, a low-pass filter circuit, a high-pass filter circuit and a power conversion circuit. The power conversion circuit provides appropriate power to other circuits.

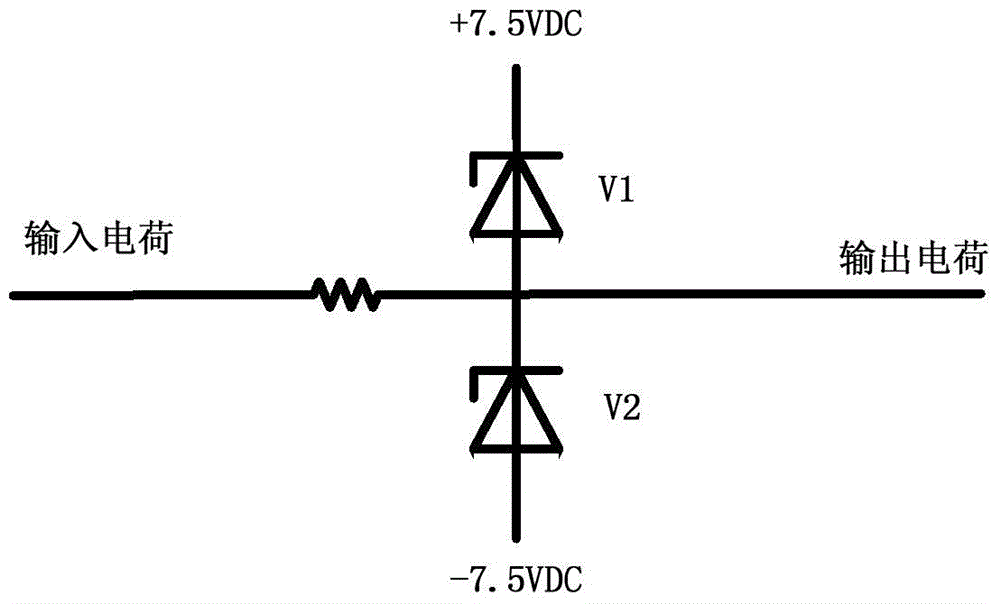

[0035] The overload protection circuit consists of protective transient suppression connected in series, such as figure 2 As shown, it is used to limit the impact of excessive charge on the subsequent circuit.

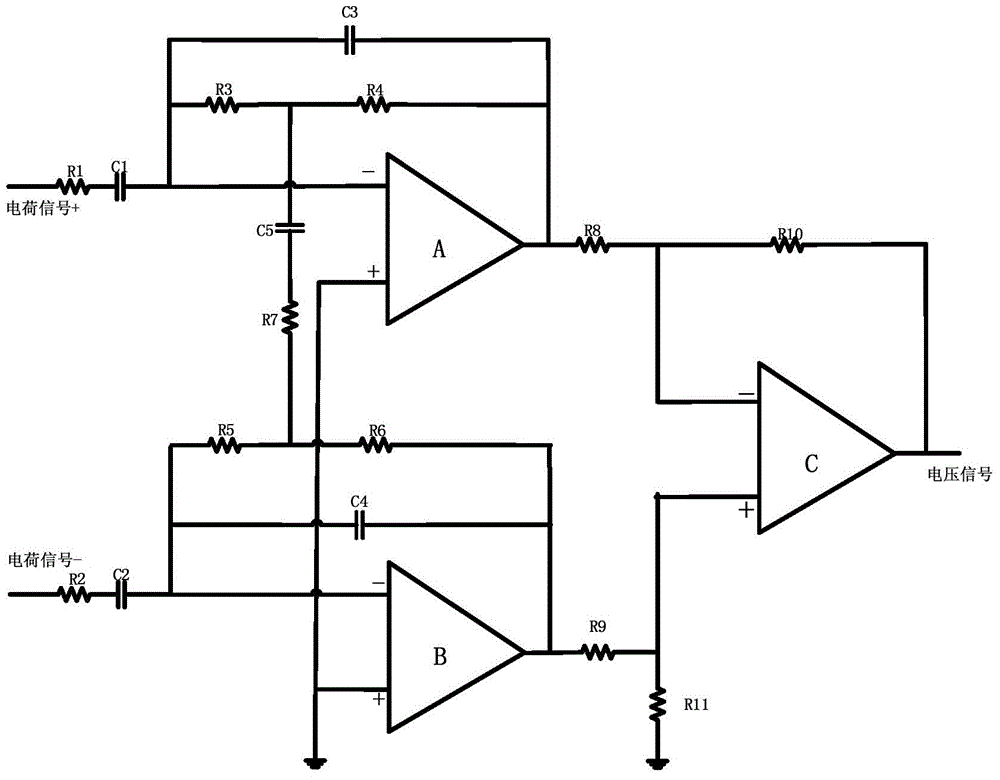

[0036] The differential charge conversion circuit is connected with the overload protection circuit, receives the charge signal passed through the overload protection circuit, and transforms it into a voltage signal after being differentially amplified. Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com