A production method of electric heating film for electric heating floor

A technology of electric heating floor and production method, which is applied in electric heating devices, ohmic resistance heating, chemical instruments and methods, etc., can solve the problems of high cost, difficult popularization and application, complicated electric heating film production process, etc., and achieves slow change and high safety factor. , the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

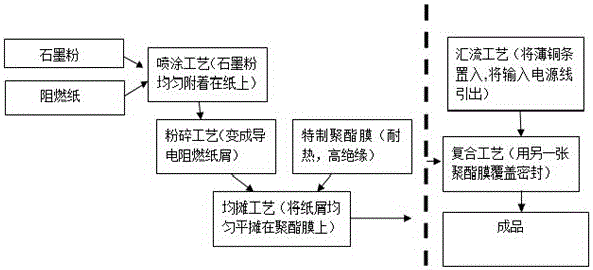

[0029] A production method of an electric heating film for an electric heating floor:

[0030] (1) Spraying: Use an electrostatic spraying machine to spray graphite powder coating on the surface of the flame-retardant paper. The thickness of the flame-retardant paper is 0.5mm, 110g / square. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece. After warm baking and solidification, the powder layer is leveled and becomes a uniform film layer, and the thickness of the film layer is controlled at 0.1mm; the amount of powder sprayed is generally controlled within the range of 70g / min, and the resistivity of the film-coated paper after spraying reaches 6Ω / cm;

[0031] During the test, the fixed width is 1 cm, and the length is selected from 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 cm paper blocks. After measurement, the resistance value per square centimeter is calculated, and the average value of 10 blocks is taken as a test whether it is ...

Embodiment 2

[0038] A production method of an electric heating film for an electric heating floor:

[0039] (1) Spraying: Use an electrostatic spraying machine to spray graphite powder coating on the front and back surfaces of the flame-retardant paper. The thickness of the flame-retardant paper is 0.8mm, 130g / square. Under the action of static electricity, the powder will be evenly adsorbed on the On the surface of the workpiece, after heating, baking and curing, the powder layer will level off and become a uniform film layer. The thickness of the film layer is controlled at 0.15mm; the amount of powder sprayed is generally controlled within the range of 80g / min. cm;

[0040] During the test, the fixed width is 1 cm, and the length is selected from 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 cm paper blocks. After measurement, the resistance value per square centimeter is calculated, and the average value of 10 blocks is taken as a test whether it is passed;

[0041] (2) Crushing: use a paper shredde...

Embodiment 3

[0047] A production method of an electric heating film for an electric heating floor:

[0048](1) Spraying: Spray graphite powder coating on the front and back surfaces of the flame-retardant paper with an electrostatic spraying machine. The thickness of the flame-retardant paper is 0.5, 130g / square. Under the action of static electricity, the powder will be evenly adsorbed on the workpiece On the surface, after heating, baking and curing, the powder layer will level off and become a uniform film layer. The thickness of the film layer is controlled at 0.15mm; the amount of powder sprayed is generally controlled within the range of 70g / min, and the resistivity of the film-coated paper after spraying reaches 6Ω / cm ;

[0049] During the test, the fixed width is 1 cm, and the length is selected from 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 cm paper blocks. After measurement, the resistance value per square centimeter is calculated, and the average value of 10 blocks is taken as a test wheth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com