Ultra-thin and small flaky silver powder and its manufacturing method

A manufacturing method, thin sheet technology, applied in the direction of cable/conductor manufacturing, metal/alloy conductors, conductors, etc., can solve problems such as unevenness, difficult coating, etc., achieve sufficient conductivity and ensure conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] As the flaky silver powder material, the flaky silver powder of Comparative Example 1 was used. 2.5 kg of this powder was put into a medium agitation type wet ultrafine pulverizer (MSC-I00, COKE & ENGINEERING CO., LTD., Nippon COKE & ENGINEERING Co., Ltd.) using micro media with a diameter of 0.1 mm, and subjected to spreading treatment. exist figure 2 The SEM photograph of the obtained extremely thin and small flaky silver powder is shown in the middle.

Embodiment 2

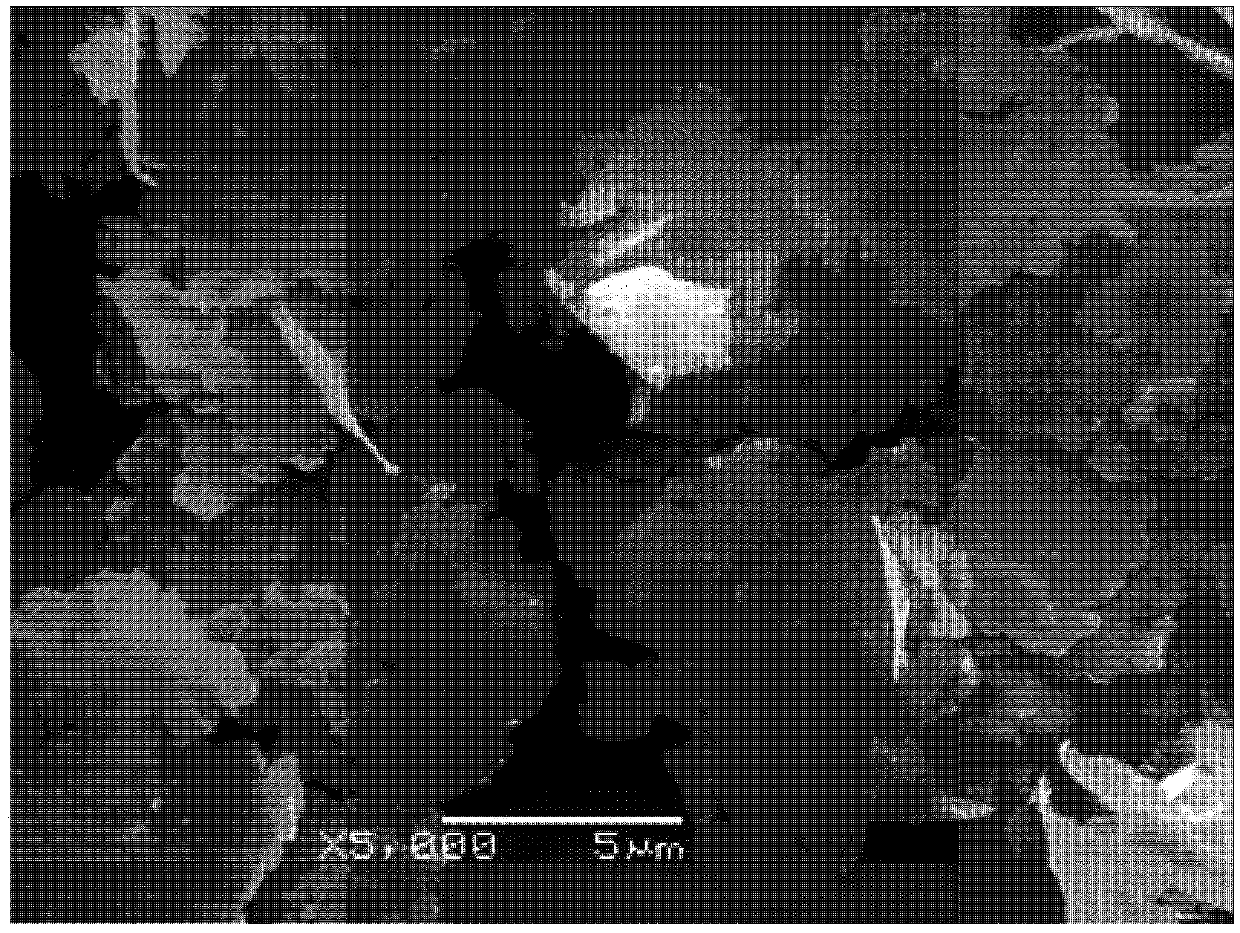

[0082] The ultra-thin flaky silver powder of Example 1 was put into a vortex airflow classifier (Nissin Engineering Co., Ltd., Aerofine Classifier AC-20) for dispersion treatment. exist image 3 The SEM photograph of the obtained extremely thin and small flaky silver powder is shown in the middle. The D of the obtained extremely thin and small flaky silver powder 50 It is 3.8μm and the average thickness is 22nm. The average thickness was measured by preparing a paste with a silver content of 75% by weight, coating it on a flat substrate, and observing its cross-section with an SEM. exist Figure 4 The middle represents the SEM photograph used in the measurement of the average thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com