Heat-diffusing sound insulation sheet and heat-diffusing sound insulation structure

A thermal diffusivity, sound insulation board technology, used in cooling/ventilation/heating renovation, sound-generating equipment, instruments, etc., can solve problems such as large vibration and sound, and achieve the effect of suppressing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

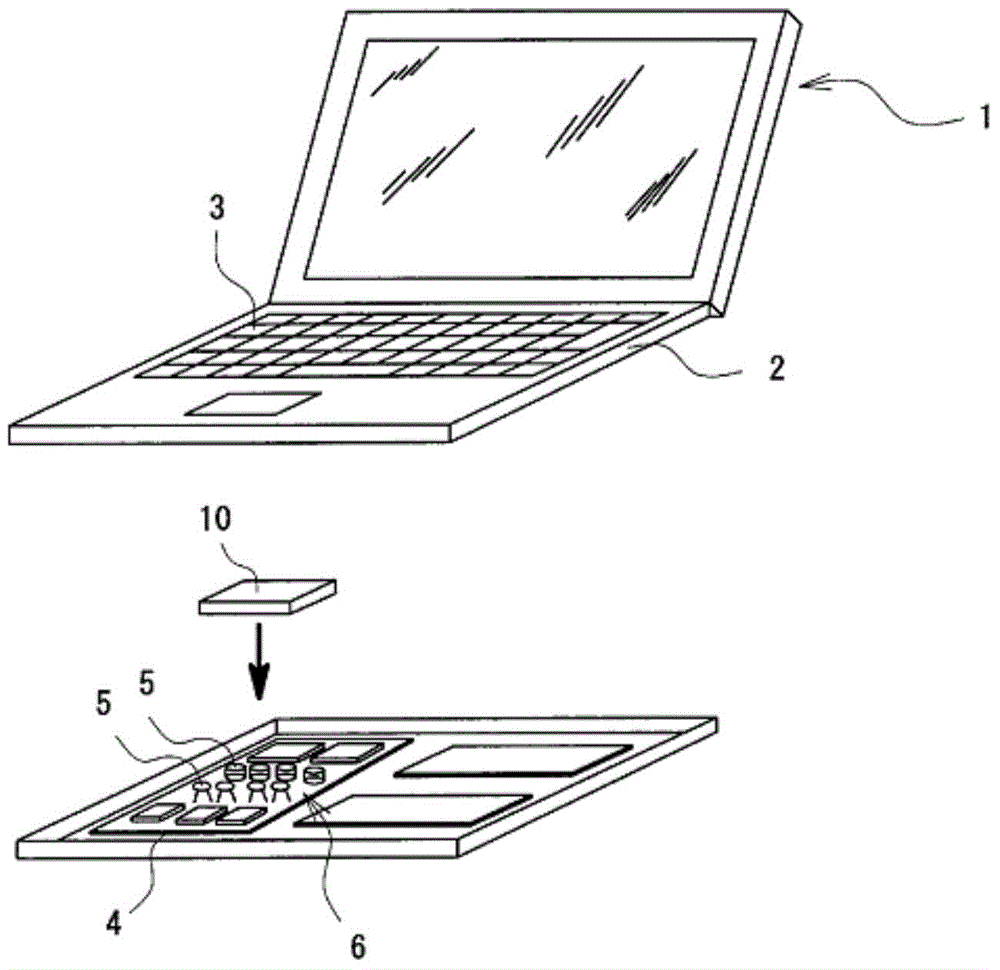

[0043] The first embodiment ( figure 2 ):

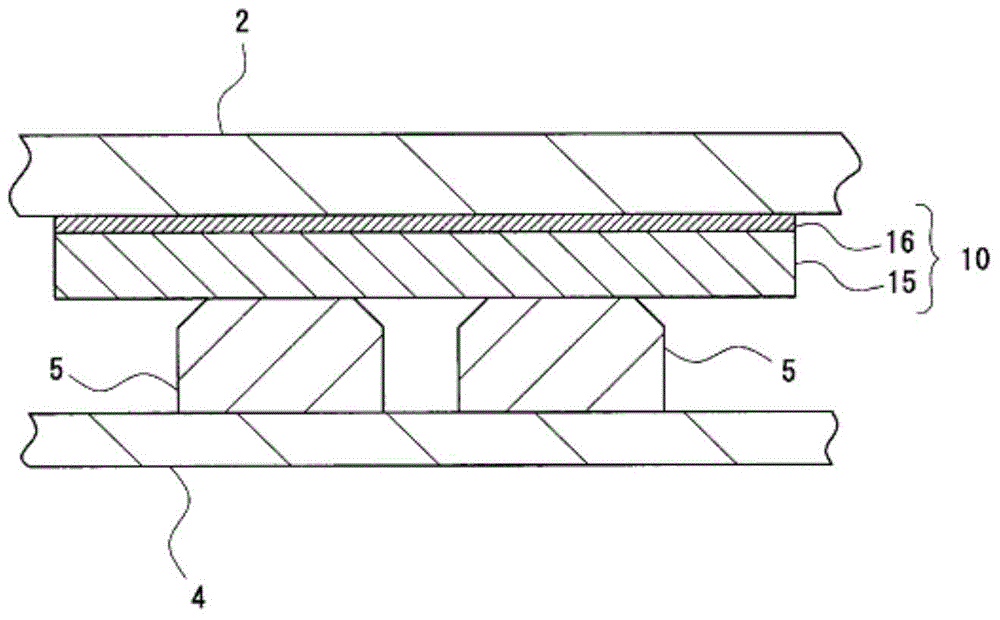

[0044] The heat diffusing sound insulating panel 10 of this embodiment includes figure 2 The sound insulating member 15 and the thermal diffusion member 16 shown are formed in the shape of laminated thin plates. Then, the heat diffusing sound insulating sheet 10 is installed in the notebook computer 1 such that the heat diffusing member 16 faces the case 2 side and the sound insulating member 15 faces the substrate 4 side.

[0045] (soundproof member)

[0046] The soundproof member 15 is made of a porous body such as a foam for blocking sound or a polymer composition filled with a hollow filler. The sound insulating member 15 has a thin plate shape and has flexibility so as to be easily attached to a narrow space such as a gap between the electronic component 5 and the case 2 .

[0047] The material of the foam is resin or rubber such as polystyrene, polyurethane, polyethylene, silicone, acrylonitrile copolymer, polyolefin ru...

no. 2 approach

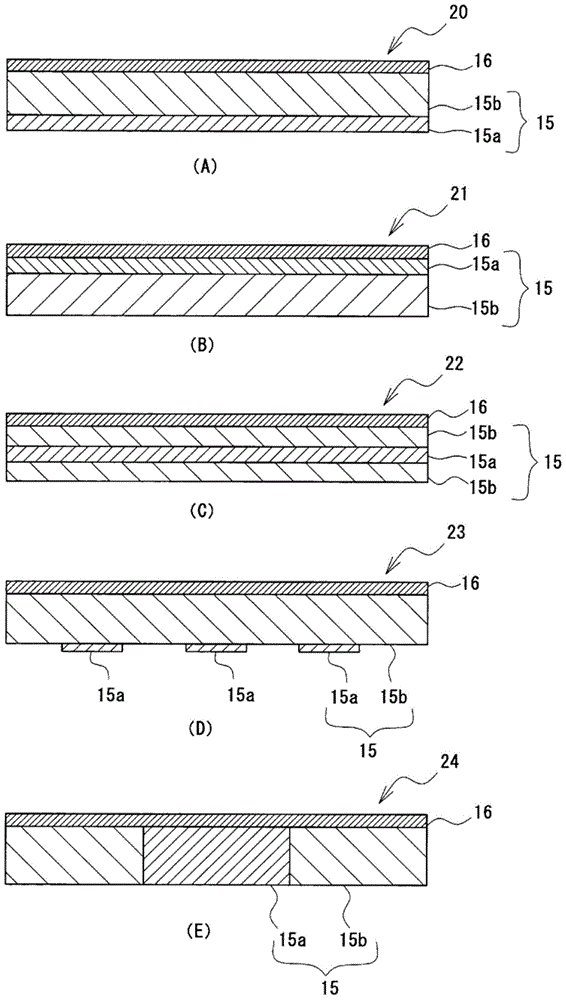

[0061] The second embodiment ( image 3 (A)):

[0062] image 3 (A) is a cross-sectional view showing the heat diffusing sound insulating panel 20 of this embodiment. The heat-diffusing sound-insulating panel 20 has a high-density layer 15a made of a foam compressed in the sound-insulating member 15, and is laminated with a standard-density layer 15b made of only a foam.

[0063] For the porous structure of the standard density layer 15b made of foam only, spherical or ellipsoidal voids are formed, but for the porous structure of the high-density layer 15a composed of compressed foam, the voids An indeterminate shape that has been deformed by pressure.

[0064] The high-density layer 15a is obtained by heating and compressing an uncompressed foam. For example, in order to make the apparent density reach 70~350kg / m 3 To some extent, the compressed foam can be used as the high-density layer 15a.

[0065] In the course of completing the present invention, experiments were...

no. 3 approach

[0090] The third embodiment ( Figure 4 (A)):

[0091] Figure 4 (A) shows the cross-sectional view of the thermal diffusivity sound insulation panel 30 of this embodiment. The heat diffusing sound insulating board 30 has a concave portion 18 protruding from the substrate 4 for accommodating the electronic component 5 . Moreover, the recessed part 18 has the window part 18a located in the position which makes the electronic component 5 and the thermal diffusion member 16 face each other.

[0092] To manufacture the heat diffusing sound insulating board 30 , the portion of the sound insulating member 15 corresponding to the electronic component 5 is punched, and the recessed portion 18 with the window portion 18 a can be formed by laminating the heat diffusing member 16 on this portion.

[0093] Since the heat diffusing sound insulating sheet 30 surrounds the electronic component 5 with the side surface 17 , it is possible to reliably prevent sound leakage in the extending...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com