Preparation method of polyamide reverse osmosis membrane

A technology of reverse osmosis membrane and polyamide, which is applied in the field of preparation of reverse osmosis membrane, can solve the problems of physical injury of operators, high requirements for corrosion resistance, high energy consumption of production line operation, etc., and achieve high water flux and low residual amount , Process mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

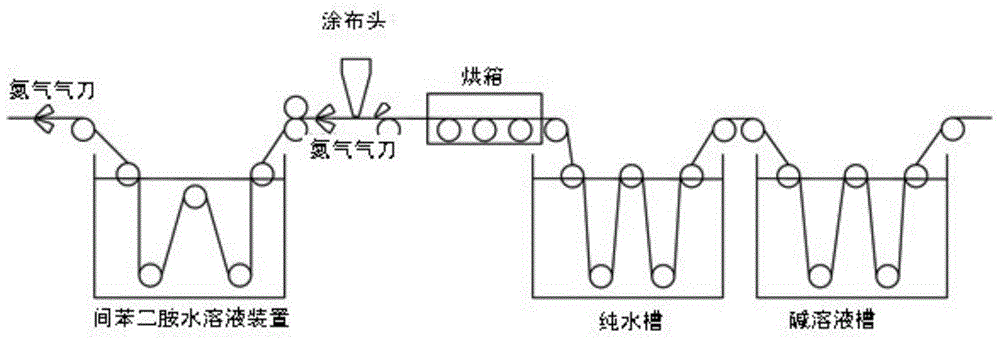

Method used

Image

Examples

Embodiment 1

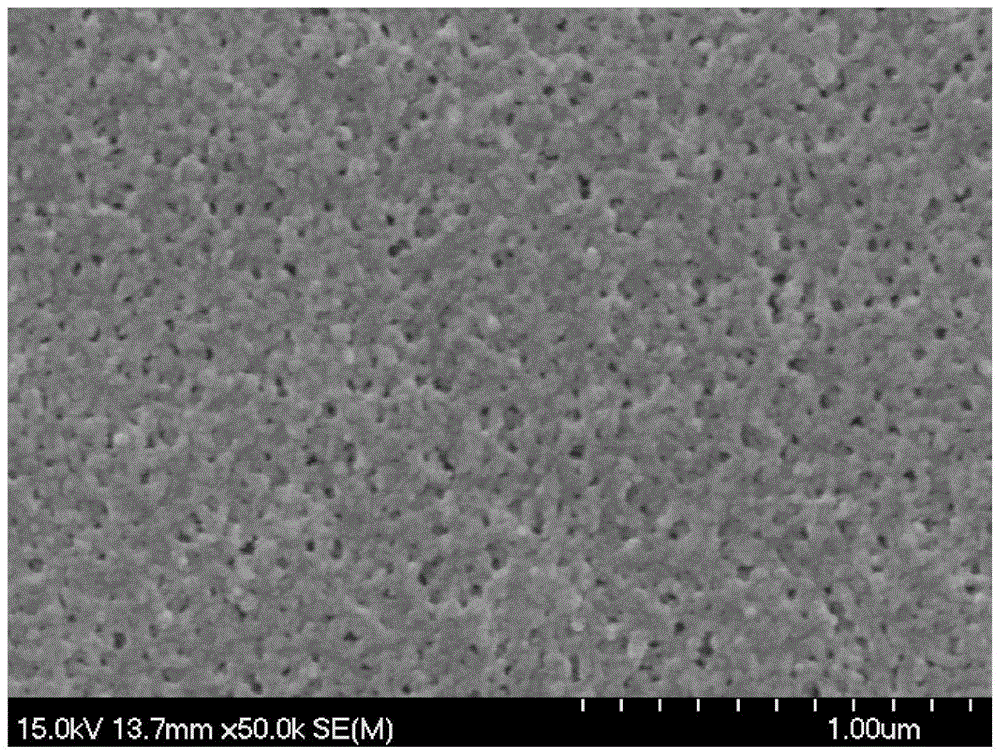

[0055] Except that the average range of surface pore diameter is between 10-30nm, the deviation value is 1.68, and the number of 20-25nm pores is 480 / um 2 , its pure water flux is 209L / m 2 / h of the porous polysulfone support membrane, the rest of the steps are the same as in Comparative Example 1.

Embodiment 2

[0057] Except that the m-phenylenediamine mass percentage concentration is 3.0 and is fully mixed to prepare an m-phenylenediamine aqueous solution with a pH of 4.99, the rest of the steps are the same as in Example 1.

Embodiment 3

[0059] The remaining steps are the same as in Example 1, except that the m-phenylenediamine mass percentage concentration is 4.0 and is fully mixed to prepare an m-phenylenediamine aqueous solution with a pH of 5.12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com