Novel morphology controllable CeO2/Cu2O catalyst for CO preferential oxidation reaction through liquid-phase reduction method

A catalyst and reduction technology, which is used in the field of liquid phase reduction method to synthesize a new type of catalyst for CO preferential oxidation reaction CeO2/Cu2O, which can solve the problems of low poisoning ability, high price and limitation, and achieve low price. , wide temperature window, good CO conversion and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

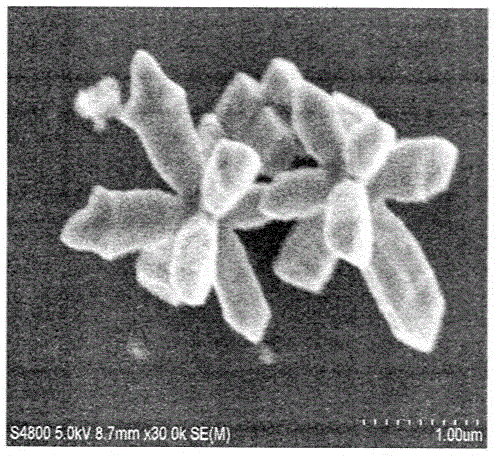

[0039] 6) Measure CuSO respectively 4 , Na 3 C 6 h 5 o 7 , Na 2 CO 3 , C 6 h 12 o 12 Add 20ml of each solution into a three-necked flask, add 400ml of deionized water, heat to 80°C, and mechanically stir for 40min.

[0040] 7) Wash the obtained precipitate by centrifugation. Wash three times with water first, and then wash three times with absolute ethanol. The precipitate was vacuum-dried at 60 °C for 12 h to obtain star-shaped Cu 2 O carrier.

[0041] 8) Take 1g (6.988mmol) of the prepared star-shaped Cu 2 Add distilled water dropwise to the O carrier until the incipient wetness, and record its water absorption as 0.5ml, which is the minimum amount of water required to wet the carrier.

[0042] 9) Take 6.988mmol Ce(NO 3 ) 3 ·6H 2 O was dissolved in 0.5ml distilled water and ultrasonicated until completely dissolved to obtain Ce(NO 3 ) 3 solution.

[0043] 10) Take 1g of the prepared star-shaped Cu 2 O carrier to Ce(NO 3 ) 3 solution, soaked for 24 hours...

Embodiment 2

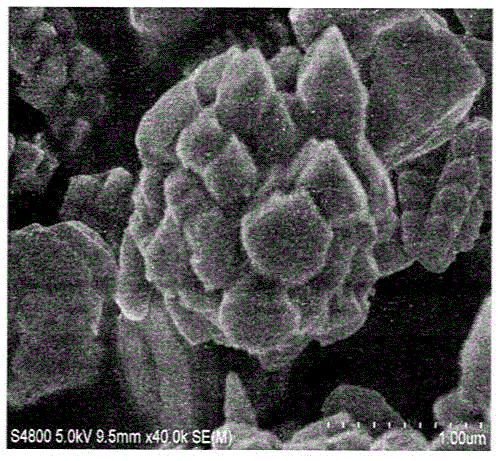

[0046] 6) Measure 20ml CuSO 4 Add the solution into a three-necked flask, add 400ml of deionized water to dissolve, add 20ml of CTAB, heat to 80°C, stir mechanically for 10-15min, then add 20ml of Na 3 C 6 h 5 o 7 and 20ml Na 2 CO 3 Mix the solution, after 10min, add 20ml C 6 h 12 o 12 The solution was mechanically stirred for 30 min.

[0047] 7) Wash the obtained precipitate by centrifugation. Wash three times with water first, and then wash three times with absolute ethanol. The precipitate was vacuum-dried at 60 °C for 12 h to obtain hollow spheres Cu 2 O carrier.

[0048] 8) Take 1g (6.988mmol) of the prepared hollow spherical Cu 2 Add distilled water dropwise to the O carrier until the incipient wetness, and record its water absorption as 0.5ml, which is the minimum amount of water required to wet the carrier.

[0049] 9) Take 6.988mmol Ce(NO 3 ) 3 ·6H 2 Ce(NO 3 ) 3 solution.

[0050] 10) Take 1g of the prepared hollow spherical Cu 2 The O carrier is d...

Embodiment 3

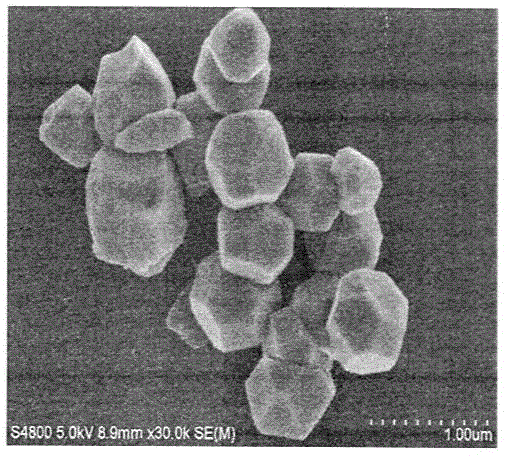

[0053] 6) Measure CuSO respectively 4 , Na 3 C 6 h 5 o 7 , Na 2 CO 3 , C 6 h 12 o 12 Add 20ml of each solution into a three-necked flask, add 400ml of deionized water, add 20ml of 2.0mM CTAB, heat to 80°C, and mechanically stir for 40min.

[0054] 7) After the obtained solution is fully precipitated, it is centrifuged and washed. Wash three times with water first, and then wash three times with absolute ethanol. The precipitate was vacuum-dried at 60 °C for 12 h to obtain polyhedral Cu 2 O carrier.

[0055] 8) Take 1g (6.988mmol) of the prepared polyhedral Cu 2 Add distilled water dropwise to the O carrier until the incipient wetness, and record its water absorption as 0.5ml, which is the minimum amount of water required to wet the carrier.

[0056] 9) Take 6.988mmol Ce(NO 3 ) 3 ·6H 2 Ce(NO 3 ) 3 solution.

[0057] 10) Take 1g of the prepared polyhedral Cu 2 The O carrier is dissolved in the Ce(NO 3 ) 3 solution, soaked for 24 hours and then vacuum-dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com