Integrated simple milling and drying device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

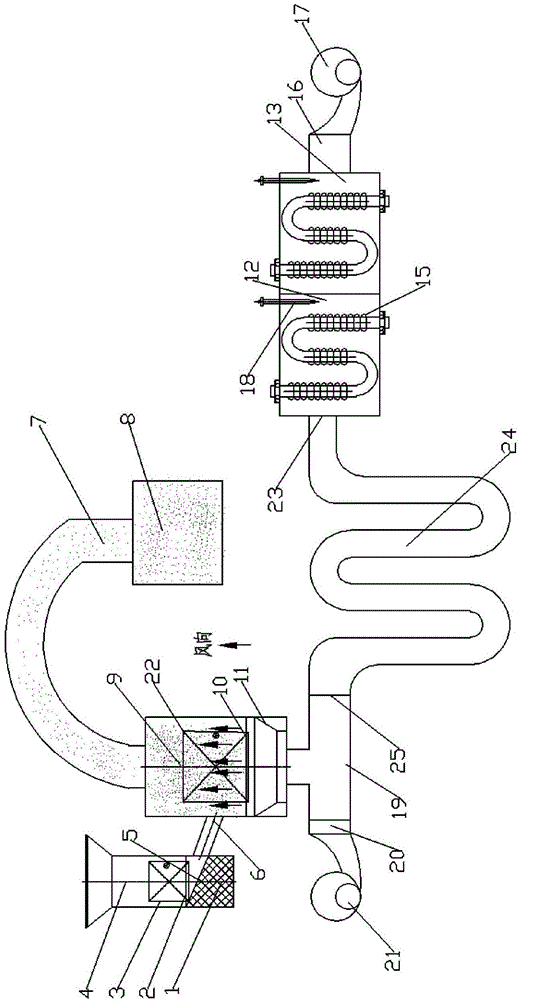

[0014] like figure 1 As shown, an integrated and simple milling and drying equipment described in the present invention mainly includes a milling system, a drying system, and a heating system.

[0015] 1) The milling system is mainly composed of motor, transmission system, milling blade, milling box 4, filter screen 1, visual window 3 and shock-absorbing rubber 1 and other main components. The milling blade is installed It is inside the milling box 4 and driven by a motor through a transmission system to rotate at a high speed to mill wood chips, wood flour and wood slag. The filter screen one 2 is fixedly installed on the countersunk hole in the milling box 4 by screws through the countersunk structure and is located under the grinding blade, and the shock-absorbing rubber 1 is placed on the milling box seat Next, it is connected and fixed on the ground by fastening screws, and a visible window 3 is provided on the described milling box body 4, which is convenient for observ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com