Ocean platform pile leg steel raw material rolling method

A technology for offshore platforms and pile legs, which is applied in the direction of metal rolling to achieve the effects of reduced energy consumption, increased productivity, and easy control of material shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

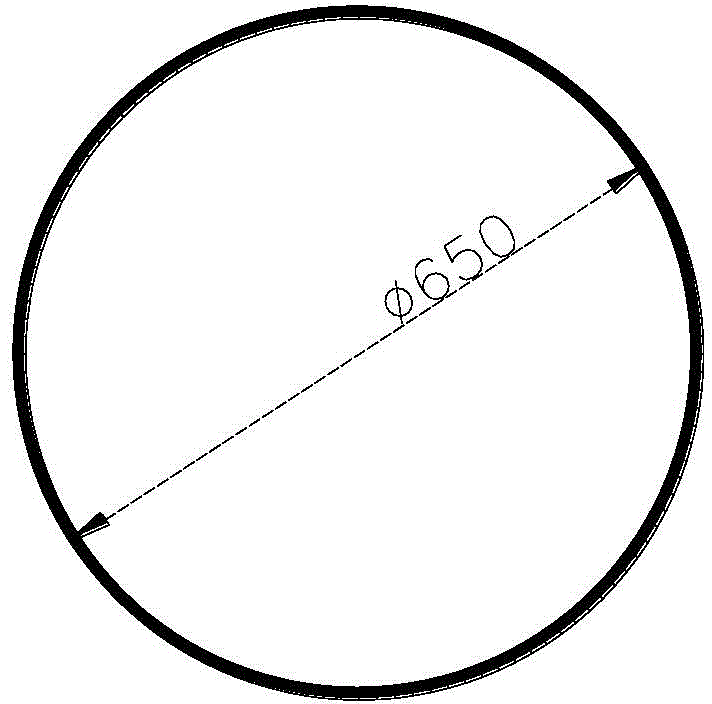

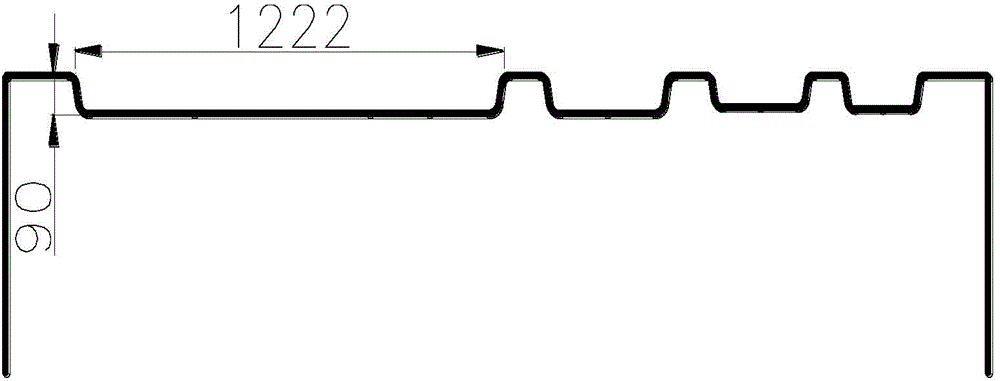

[0030] Use qualified continuous casting round billets, with cross-sectional dimensions as attached figure 1 As shown, it is φ650mm. According to the conventional method, the continuous casting round billet is sent to the heating furnace and heated to about 1250°C. After the high-pressure water is discharged from the furnace, the billet that has deviated in the roller table is pushed and rolled by the pusher and the clamping plate. Line and sent to the roughing mill for multi-pass rolling (pass image 3 As shown, a total of 7 passes are rolled, and the section of the billet after rolling is shown in the attached file. Figure 4 As shown, the height is 380mm and the width is 860mm. Then, the produced offshore platform legs are hoisted and collected with steel raw materials to complete the production process.

[0031] The invention is suitable for φ650mm~φ800mm continuous casting round cast billet rolling offshore platform leg steel material. The billet has a large unit weight, a hi...

Embodiment 2

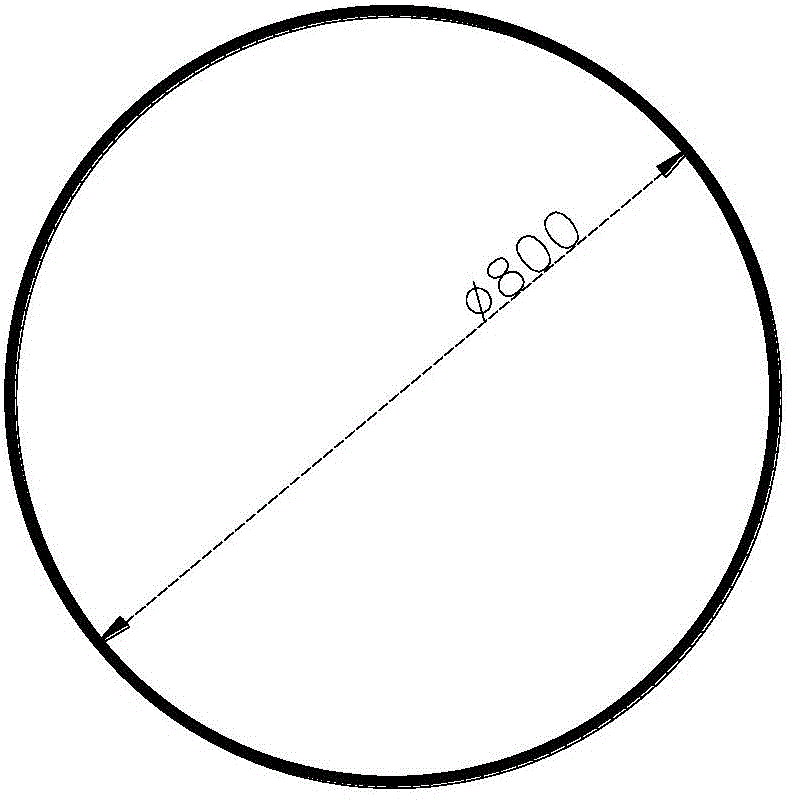

[0033] Use qualified continuous casting round billets, with cross-sectional dimensions as attached figure 2 As shown, it is φ800mm. According to the conventional method, the continuous casting round billet is sent to the heating furnace to be heated to about 1250°C. After being discharged from the furnace, the billet that has deviated during the roller table transportation is pushed to the straight and the centering rolling line by the pusher and the clamping plate. It is sent to the rough rolling mill for multi-pass rolling (the pass type is as attached) image 3 Shown), a total of 9 passes are rolled, and the cross section of the rolled billet is shown in the attached file. Figure 5 As shown, the height is 330mm and the width is 695mm. Then, the produced offshore platform legs are hoisted and collected with steel raw materials to complete the production process.

[0034] The invention is suitable for φ650mm~φ800mm continuous casting round cast billet rolling offshore platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com