Preparation method of beta-cyclodextrin stabilized embedded nanoscale zero-valent iron

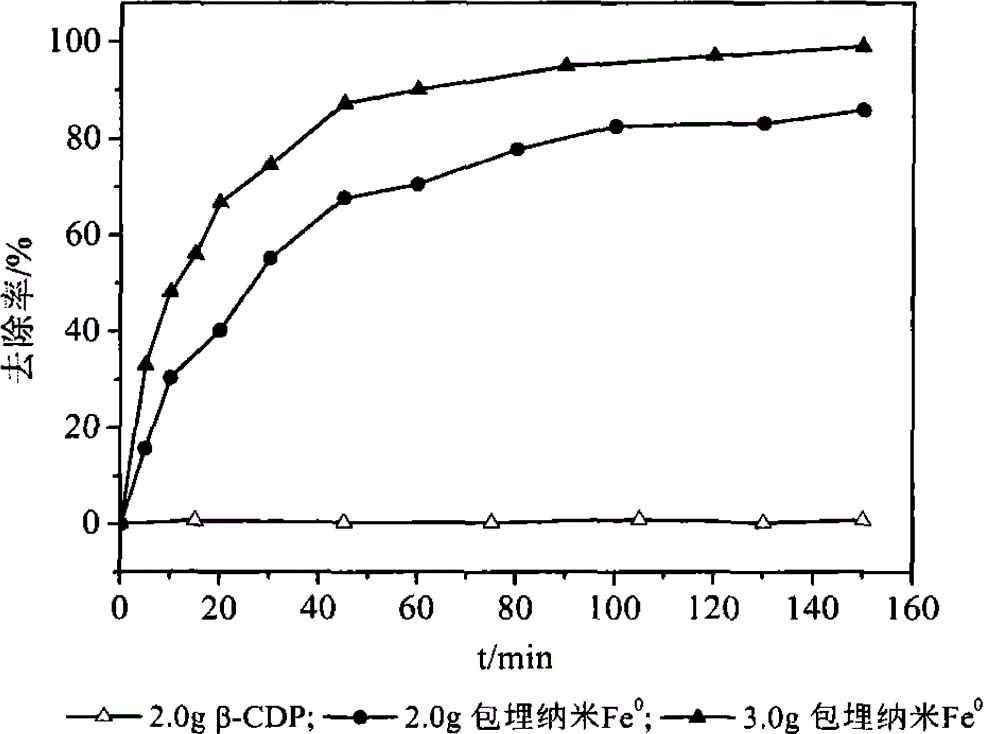

A technology of nano-zero-valent iron and cyclodextrin, which is applied in coatings and other directions, can solve the problems of reduced reaction rate and instability of nano-zero-valent iron, and achieve high bioavailability, recycling, high reactivity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

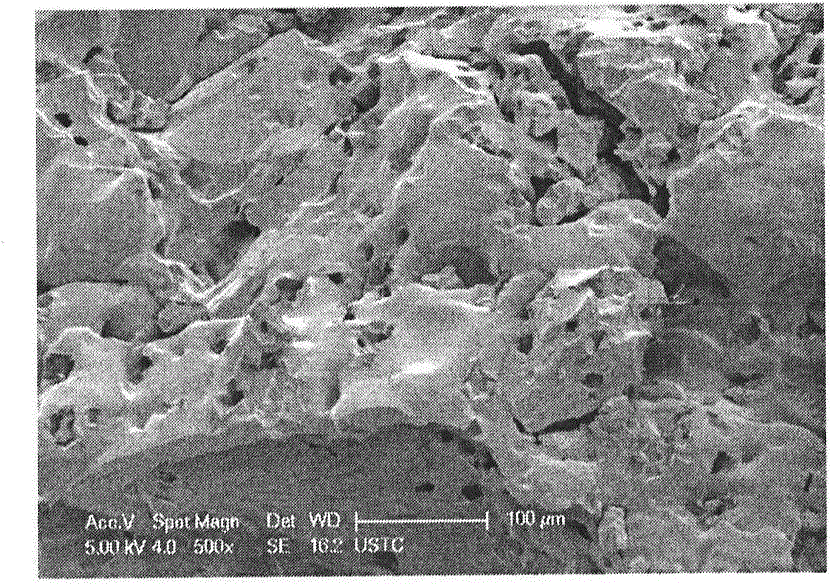

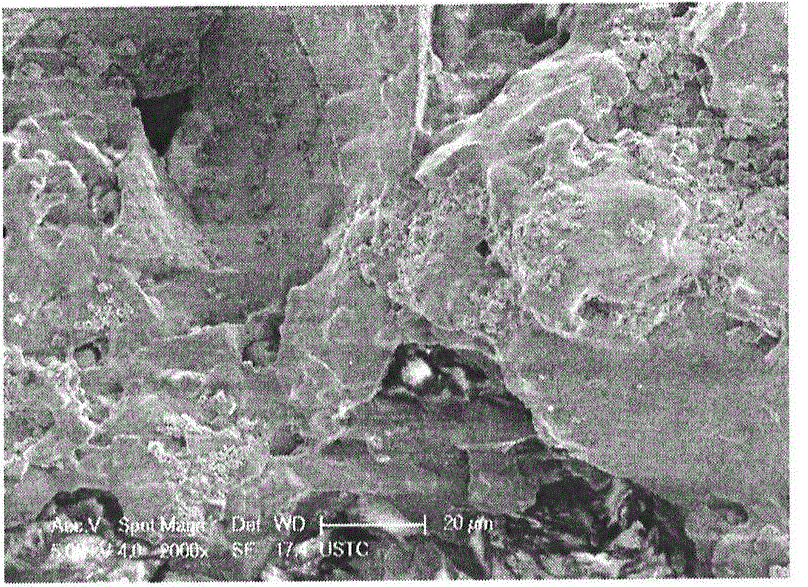

Embodiment 1

[0046] Under the condition of nitrogen protection, add 200mg of nano-zero-valent iron, 6.0g of β-cyclodextrin and 15mL of 50% NaOH solution into a 250mL three-necked flask, and stir with an electric stirrer until it becomes a paste in a water bath at 60°C, and stir at a speed of 230rpm. Use a constant pressure dropping funnel to add 10mL of epichlorohydrin solution drop by drop. After 15 minutes, the dropwise addition is completed. Continue to stir for 0.5-1.0h until a block-shaped gel appears. Stop stirring and continue to react for 0.5h. Rinse the Buchner funnel with deoxygenated water and deoxygenated ethanol to neutrality, and after drying, black β-cyclodextrin polymer embeds nanometer zero-valent iron.

Embodiment 2

[0048] Under the condition of nitrogen protection, add 200mg of nano-zero-valent iron, 6.0g of β-cyclodextrin and 15mL of 50% NaOH solution into a 250mL three-necked flask, and stir with an electric stirrer until it becomes a paste in a water bath at 60°C, and stir at a speed of 230rpm. Use a constant pressure dropping funnel to add 15mL of epichlorohydrin solution drop by drop. After 15 minutes, the dropwise addition is completed. Continue to stir for 0.5-1.0h until a block-like gel appears. Stop stirring and continue to react for 0.5h. Take out the embedding. Rinse the Buchner funnel with deoxygenated water and deoxygenated ethanol to neutrality, and after drying, black β-cyclodextrin polymer embeds nanometer zero-valent iron.

Embodiment 3

[0050] Under the condition of nitrogen protection, add 200mg of nano-zero-valent iron, 6.0g of β-cyclodextrin and 10mL of 50% NaOH solution into a 250mL three-necked flask, and stir it with an electric stirrer until it becomes a paste in a water bath at 60°C, stirring at a speed of 230rpm, while Use a constant pressure dropping funnel to add 10mL of epichlorohydrin solution drop by drop. After 15 minutes, the dropwise addition is completed. Continue to stir for 0.5-1.0h until a block-shaped gel appears. Stop stirring and continue to react for 0.5h. Rinse the Buchner funnel with deoxygenated water and deoxygenated ethanol to neutrality, and after drying, black β-cyclodextrin polymer embeds nanometer zero-valent iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com