Laser etching method of transparent conductive thin film

A technology of transparent conductive film and laser etching method, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex implementation and high requirements for laser focusing accuracy, and achieve the requirements of reducing laser focusing accuracy and reliability Good, reasonably priced results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

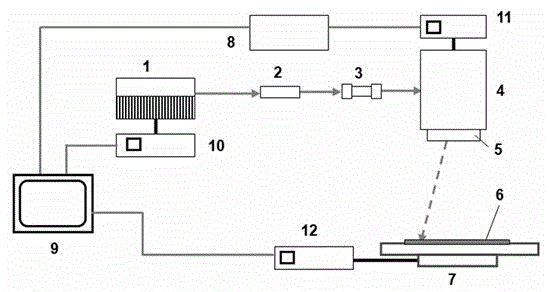

[0029] Embodiment one: see figure 1 Shown, a kind of laser etching method of transparent conductive film, comprises the steps:

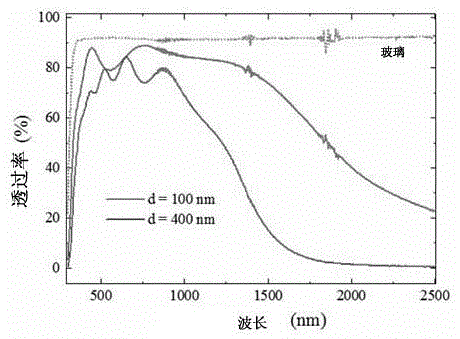

[0030] (1) A short-wavelength infrared pulse laser is used to output a pulse laser with a wavelength between 1.4 μm and 3.0 μm, and the pulse width is 0.1 ns to 800 ns, and it is collimated. The short-wavelength infrared pulse laser is a fiber laser with a single pulse The laser energy is 1-2000 microjoules, and the pulse frequency is 1 kHz to 1 MHz;

[0031](2) irradiating the pulsed laser beam onto the film substrate placed on the two-dimensional translation stage, controlling the relative movement of the laser beam and the two-dimensional translation stage, so that the focal point of the laser beam moves on the transparent conductive film according to a set path, Etching is carried out, and the relative movement speed of the laser and the transparent conductive film is controlled to be 50mm / s-9000mm / s, and the overlapping degree of the light spo...

Embodiment 2

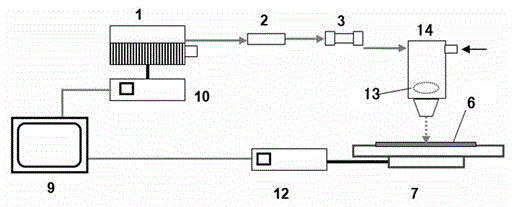

[0033] Embodiment two: see figure 2 Shown, a kind of laser etching method of transparent conductive film, comprises the steps:

[0034] (1) A short-wavelength infrared pulse laser is used to output a pulse laser with a wavelength between 1.4 μm and 3.0 μm, and the pulse width is 0.1 ns to 800 ns, and it is collimated. The short-wavelength infrared pulse laser is a fiber laser with a single pulse The laser energy is 1-2000 microjoules, and the pulse frequency is 1 kHz to 1 MHz;

[0035] (2) irradiating the pulsed laser beam onto the film substrate placed on the two-dimensional translation stage, controlling the relative movement of the laser beam and the two-dimensional translation stage, so that the focal point of the laser beam moves on the transparent conductive film according to a set path, Etching is carried out, and the relative movement speed of the laser and the transparent conductive film is controlled to be 50mm / s-9000mm / s, and the overlapping degree of the light s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com