Processing method and clamp for thin-wall double-channel structure welding assembly

A technology for welding components and processing methods, applied in welding accessories, manufacturing tools, welding equipment, etc., can solve the problems of welding seam fatigue cracks, uncontrollable fatigue cracks on ship-based combustion engines, cracks falling off blocks, etc., to achieve high welding strength, Break through the technical bottleneck of crack removal and enhance the effect of root penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

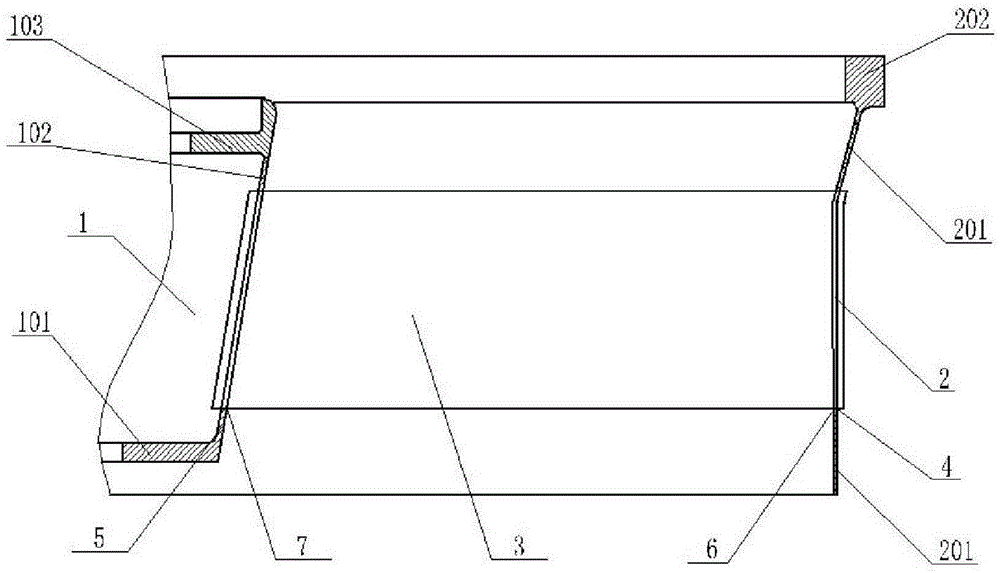

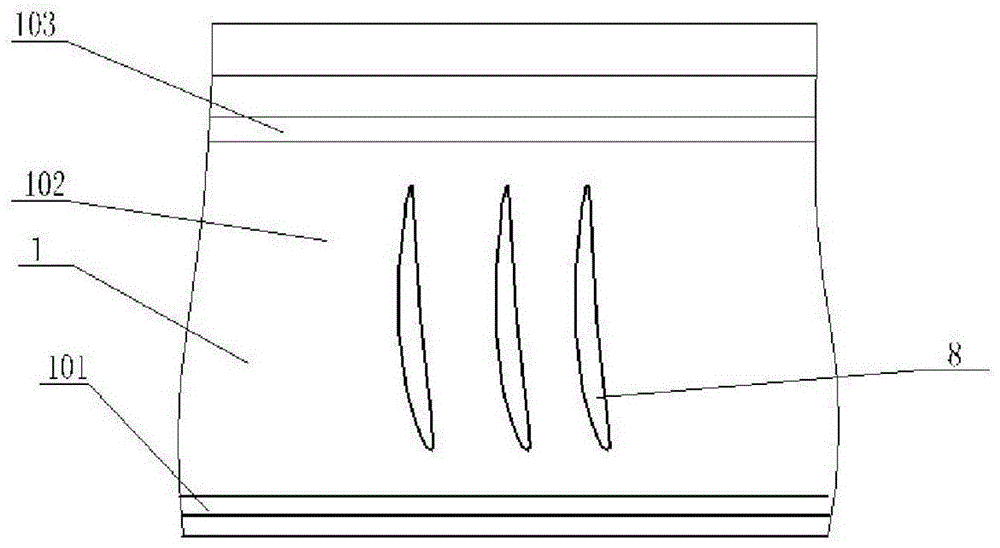

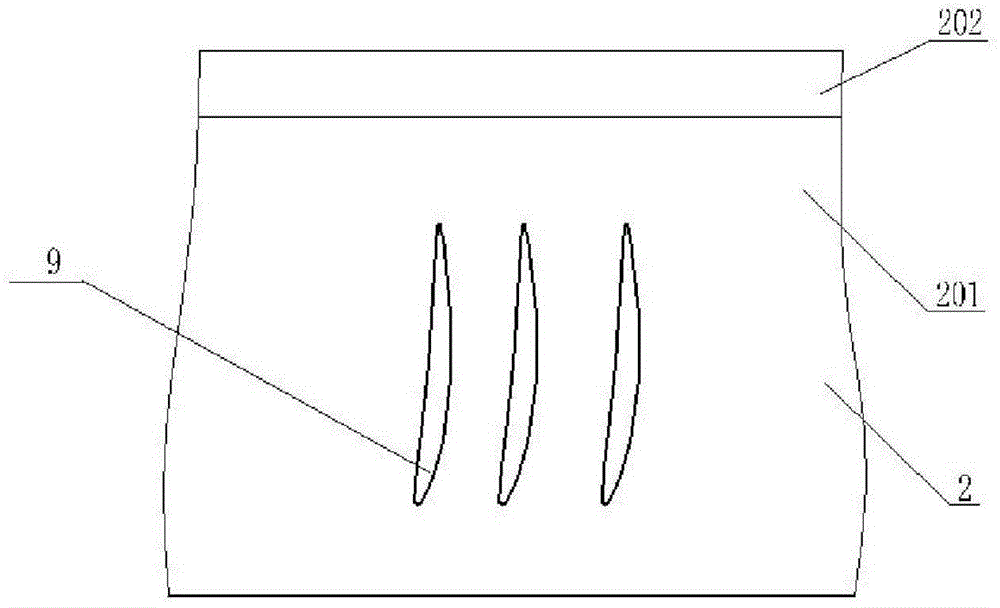

[0035] Such as figure 1 As shown, the thin-walled double-runner welded assembly has a complex structure, consisting of inner and outer runner welded assemblies with different thicknesses and rectifying blades 3, which is equivalent to the turbine rear casing with a sheet metal structure, which integrates laser processing, welding, and lathe processing. Integrating, boring, and non-destructive testing processes, there are as many as 96 fillet welds formed by the welding components of the inner and outer runners and the rectifier blades, which brings great difficulty to the stability of the overall welding and machining; thin-walled double runners The structural welding components are made of high-temperature alloy GH536 material, and shrinkage deformation occurs in the welding area by the existing technology, and the deformation stress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com