Joint of mechanical arm

A technology of mechanical arms and joints, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of large joint volume of mechanical arms, and achieve the effects of small size, compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

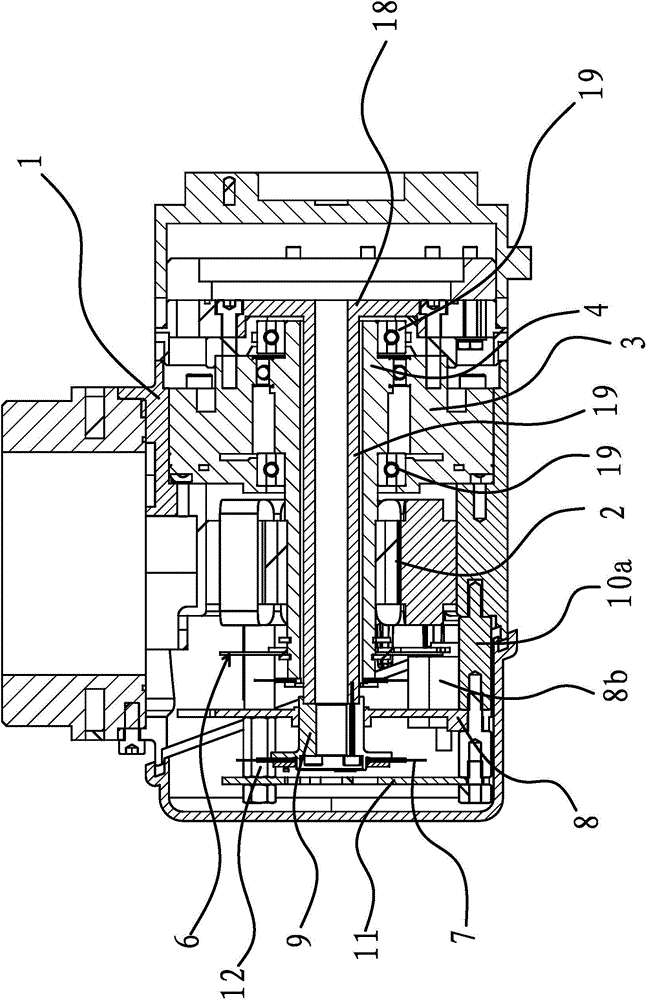

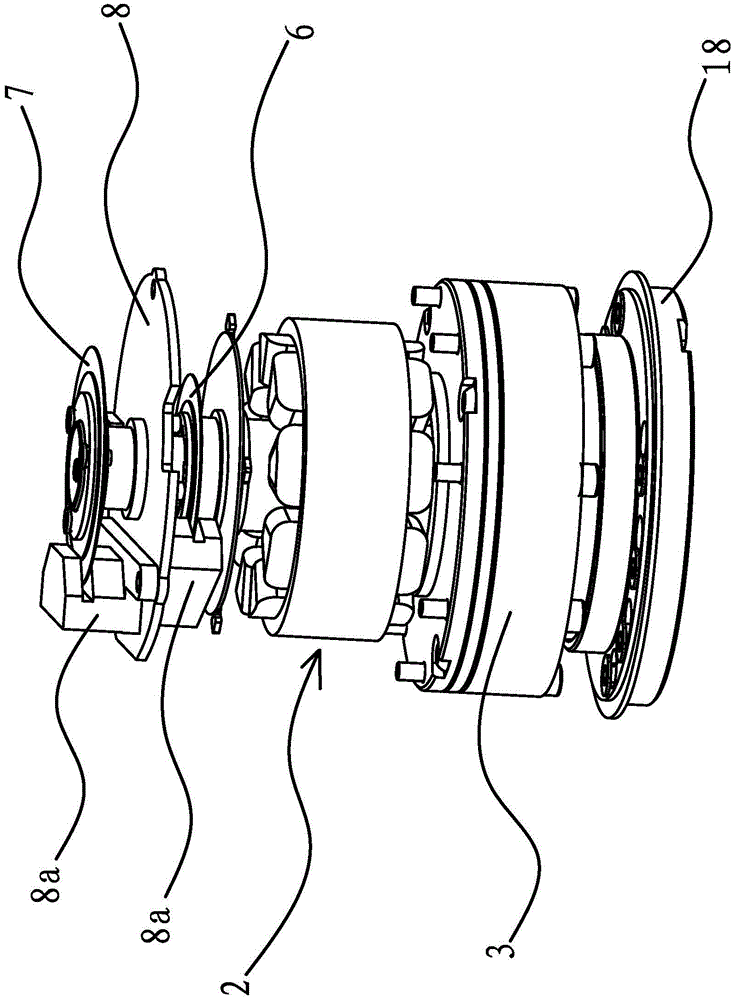

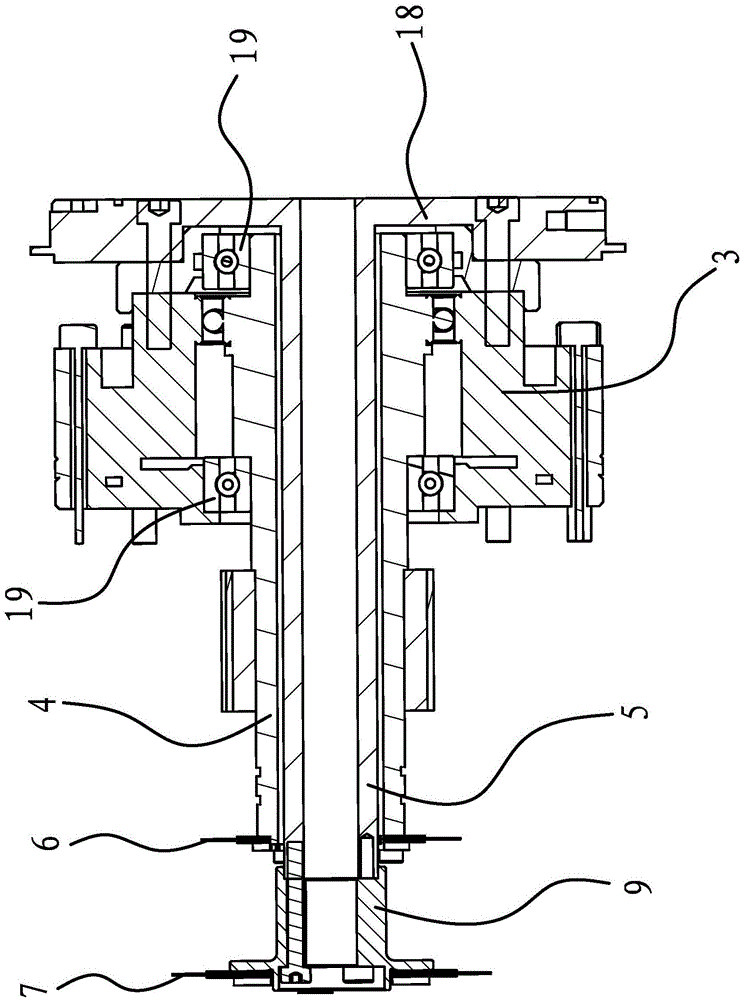

[0042] Such as figure 1 with image 3 As shown, a joint of a mechanical arm includes a casing 1, a motor 2 and a harmonic reducer 3 integrated in the casing 1, the motor 2 is located in the middle of the casing 1, the harmonic reducer 3 is located at one end of the casing 1, and the motor 2 The rotating shaft 4 penetrates into the harmonic reducer 3, and a bearing 19 is arranged between the part of the rotating shaft 4 penetrating into the harmonic reducer 3 and the harmonic reducer 3, and the bearing 19 supports the rotating shaft 4 of the motor 2, The rotating shaft 4 of the motor 2 can be used as the input end of the harmonic reducer 3 at the same time, the inner end of the output shaft 5 is integrally formed with a flange 18, and the output shaft 5 and the output end of the harmonic reducer 3 pass through the flange The disc 18 is fixed by the fasteners inserted into the harmonic reducer 3 . The output shaft 5 penetrates into the rotating shaft 4 of the motor 2 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com