High-strength plant fiber material

A plant fiber material and plant fiber technology, applied in the field of high-strength plant fiber materials, can solve the problems of inconsistent mechanical properties of elastic materials, collapse of elastic materials, bulging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

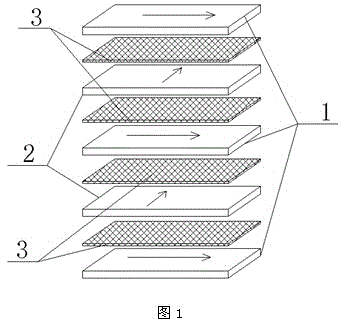

[0034] Embodiment 1 of the present invention: a high-strength plant fiber material, which is formed by stacking multiple layers of plant fiber elastic sheets. When the plant fiber elastic sheet is produced, the direction along the production line is used as the longitudinal direction, and the The direction of the vertical production line of the plant fiber elastic sheet is taken as the transverse direction. The produced elastic sheet is in the vertical direction, and it is in the horizontal direction after being rotated 90 degrees. as attached figure 1 As shown, when this material is made, the plant fiber material can be obtained by staggered stacking more than one layer of longitudinal elastic sheet 1 and more than one layer of transverse elastic sheet 2, and the plant fiber elastic sheet is stacked vertically and horizontally. Compared with the materials obtained by stacking in the same direction, the transverse and longitudinal strength properties of the material are relat...

Embodiment 2

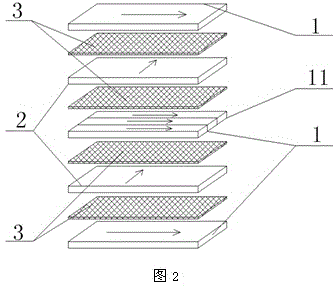

[0035]Embodiment 2 of the present invention: a high-strength plant fiber material, which is formed by stacking multiple layers of plant fiber elastic sheets. When the plant fiber elastic sheet is produced, the direction along the production line is used as the longitudinal direction, and the The direction of the vertical production line of the plant fiber elastic sheet is taken as the transverse direction. During the production of this material, the plant fiber material can be obtained by staggering stacking more than one layer of longitudinal elastic sheets 1 and more than one layer of transverse elastic sheets 2. There are 3 layers of long sisal. as attached Figure 2-4 As shown, the difference between this embodiment and Embodiment 1 is that at least one longitudinal elastic sheet 1 in the longitudinal elastic sheet 1 is formed by splicing at least two longitudinal elastic sheet blocks 11 . For example: when the material contains 7 longitudinal elastic sheets 1, 3 of the ...

Embodiment 3

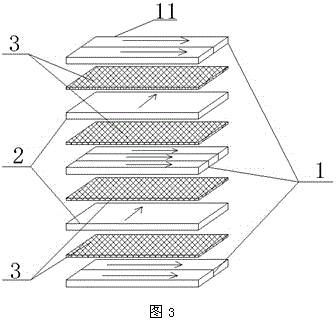

[0037] Embodiment 3 of the present invention: a high-strength plant fiber material, which is formed by stacking many layers of plant fiber elastic sheets. When the plant fiber elastic sheet is produced, the direction along the production line is used as the longitudinal direction, and the The direction of the vertical production line of the plant fiber elastic sheet is taken as the transverse direction. During the production of this material, the plant fiber material can be obtained by stacking more than one layer of longitudinal elastic sheet 1 and more than one layer of transverse elastic sheet 2, and between the longitudinal elastic sheet 1 and the transverse elastic sheet 2 Long sisal layer 3. as attached Figure 5-7 As shown, the difference between this embodiment and Embodiment 1 is that at least one transverse elastic sheet 2 in the transverse elastic sheet 2 is formed by splicing two or more transverse elastic sheet blocks 21 . For example: when the material contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com