A kind of concrete viscosity modifier and preparation method thereof

A viscosity modifier and concrete technology, applied in the field of concrete admixtures, can solve the problems of incompatibility and low concrete strength, and achieve the effects of good compatibility, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

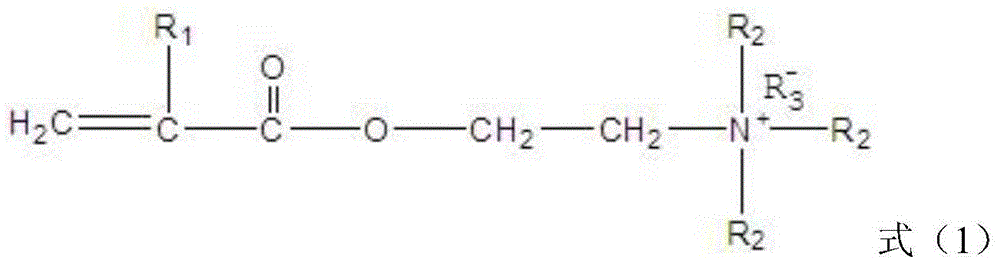

Method used

Image

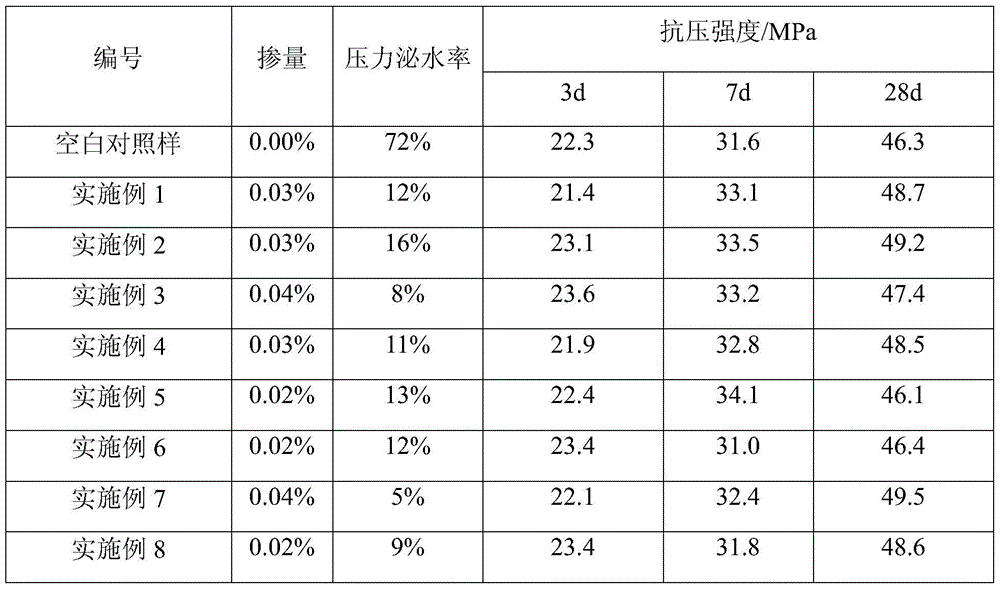

Examples

Embodiment 1

[0026] A concrete viscosity regulator, the monomer ratio involved is acryloyloxyethyltrimethylammonium chloride, acrylic acid, N,N'-methylenebisacrylamide in a molar ratio of 1:0.5:0.01, which The preparation method comprises the following steps:

[0027] Add 300g of deionized water, 38.6g of acryloyloxyethyltrimethylammonium chloride, 7.2g of acrylic acid , 0.31g of N,N'-methylenebisacrylamide, and stirred at 70°C until all the monomers were dissolved. Nitrogen gas was introduced into the flask to replace the air in the flask. Then 0.46 g of ammonium persulfate was added to the flask, stirring was continued and the internal temperature of the flask was kept at 70°C to start polymerization. React at constant temperature for 4 hours, lower the temperature to 40°C, and then adjust the pH of the solution to about 6 with a 30 wt% aqueous sodium hydroxide solution to obtain a concrete viscosity regulator with a solid content of about 13%.

[0028] The concrete viscosity modifier...

Embodiment 2

[0030] A concrete viscosity regulator, the molar ratio of the monomer acryloyloxyethyltrimethylammonium chloride, acrylic acid, and N,N'-methylenebisacrylamide is 1:1:0.02, and its preparation method includes The following steps:

[0031] Acryloyloxyethyltrimethylammonium chloride, acrylic acid, and N,N'-methylenebisacrylamide were added to a four-necked flask equipped with a dropping device, a stirrer, a condenser, a thermometer, and a nitrogen gas introduction device. 300g of deionized water, 38.6g of acryloyloxyethyltrimethylammonium chloride, 14.4g of acrylic acid, 0.62g of N,N'-methylenebisacrylamide, and stirred at 65°C until all monomers dissolve. Nitrogen gas was introduced into the flask to replace the air in the flask. Then 0.84 g of ammonium persulfate was added to the flask, stirring was continued and the internal temperature of the flask was maintained at 65°C to start polymerization. React at constant temperature for 4 hours, lower the temperature to 40°C, and...

Embodiment 3

[0034] A concrete viscosity regulator, the molar ratio of the monomer acryloyloxyethyltrimethylammonium chloride, acrylic acid, and N,N'-methylenebisacrylamide is 1:1:0.1, and its preparation method includes The following steps:

[0035] In a four-neck flask equipped with a dropping device, a stirrer, a condenser, a thermometer, and a nitrogen introduction device, add 500 g of deionized water, 38.6 g of acryloyloxyethyltrimethylammonium chloride, and 14.4 g of acrylic acid , 3.1 g of N,N'-methylenebisacrylamide, and stirred at 60° C. until all the monomers were dissolved. Nitrogen gas was introduced into the flask to replace the air in the flask. Then 0.51 g of ammonium persulfate was added to the flask, stirring was continued and the internal temperature of the flask was kept at 60°C to start polymerization. React at constant temperature for 5 hours, lower the temperature to 40°C, and then adjust the pH of the solution to about 7 with a 30 wt% aqueous sodium hydroxide solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com