Automobile bearing retainer material and preparation method thereof

A technology for automotive bearings and cages, applied in the field of materials, can solve problems such as poor mechanical properties and stability, and achieve the effects of good fatigue and chemical resistance, low sensitivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

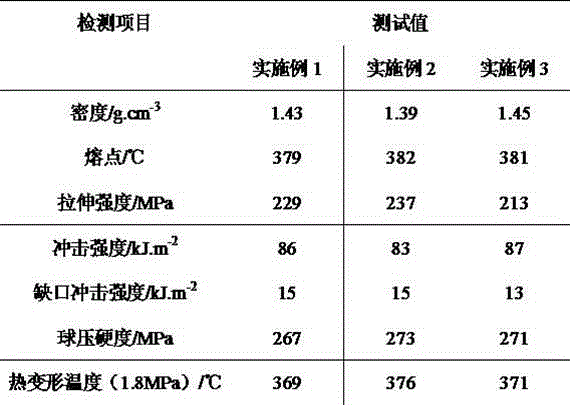

Examples

Embodiment 1

[0017] This embodiment provides an automobile bearing cage material, including polyphthalamide (PPA), polyphenylene ester, glass fiber, heat stabilizer, ethylene-octene copolymer and sizing agent, and the mass of each component is 100%. The content is: 50% polyphthalamide, 11% polyphenylene, 16% glass fiber, 5% heat stabilizer, 15% ethylene-octene copolymer, and 3% sizing.

[0018] A preparation method for an automobile bearing cage material, comprising the steps of:

[0019] (1) Select raw materials according to mass percentage, polyphthalamide is dried, the drying temperature is 90 ℃ ~ 130 ℃, the drying time is 4.5h-5h, polyphenylene is dried, the drying temperature is 100℃~110℃, drying time is 3h-4h;

[0020] (2) Put the dried polyphthalamide and polyphenylester into the high-speed mixer, and add the heat stabilizer, ethylene-octene copolymer and sizing agent in proportion;

[0021] (3) Add the above compound into the twin-screw extruder, add glass fiber into the other fe...

Embodiment 2

[0025] This embodiment provides a kind of automobile bearing cage material, including polyphthalamide (PPA), polyphenylene ester, glass fiber, heat stabilizer, toughening agent and sizing agent, the mass percentage content of each component is : 55% polyphthalamide, 10% polyphenylene, 15% glass fiber, 5% heat stabilizer, 12% toughening agent, and 3% sizing.

[0026] A preparation method for an automobile bearing cage material, comprising the steps of:

[0027] (1) Select raw materials according to mass percentage, polyphthalamide is dried, the drying temperature is 90 ℃ ~ 130 ℃, the drying time is 4.5h-5h, polyphenylene is dried, the drying temperature is 100℃~110℃, drying time is 3h-4h;

[0028] (2) Put the dried polyphthalamide and polyphenylene into the high-speed mixer, and add the heat stabilizer, toughening agent and sizing agent in proportion;

[0029] (3) Add the above-mentioned mixture into the twin-screw extruder, add glass fiber into the other feeding port of the ...

Embodiment 3

[0033] A kind of automobile bearing cage material, including: polyphthalamide (PPA), polyphenylene ester, glass fiber, heat stabilizer, ethylene-octene copolymer and sizing agent, the mass percentage content of each component is : 60% polyphthalamide, 10% polyphenylene, 18% glass fiber, 5% heat stabilizer, 15% ethylene-octene copolymer, 2% sizing.

[0034] A preparation method for an automobile bearing cage material, comprising the steps of:

[0035] (1) Select raw materials according to mass percentage, polyphthalamide is dried, the drying temperature is 90 ℃ ~ 130 ℃, the drying time is 4.5h-5h, polyphenylene is dried, the drying temperature is 100℃~110℃, drying time is 3h-4h;

[0036] (2) Put the dried polyphthalamide and polyphenylester into the high-speed mixer, and add the heat stabilizer, ethylene-octene copolymer and sizing agent in proportion;

[0037] (3) Add the above-mentioned mixture into the twin-screw extruder, add glass fiber into the other feeding port of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com