Ultraviolet-proof adhesive for glass functional film

An anti-ultraviolet and adhesive technology, applied in the direction of film/flake adhesive, adhesive, non-polymer adhesive additive, etc. and other problems, to achieve the effect of excellent UV shielding function, low yellow index and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

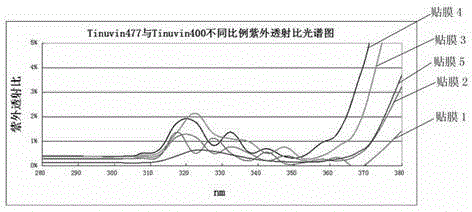

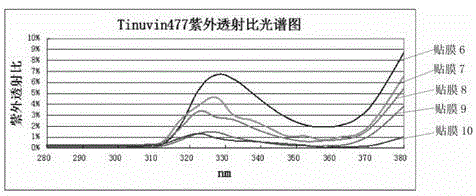

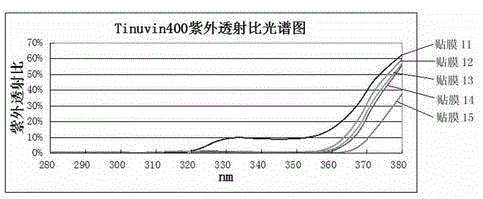

[0020] 1. The formula of the adhesive (Tinuvin477: Tinuvin400=2:1)

[0021] 2. Preparation of glass film

[0022] Mix the components of the above formula uniformly and stir for 5-10 minutes to obtain a viscosity of 70-120cps

[0023] The visco-collagen solution is made of a PET base film with a thickness of 23um (the base film itself has an ultraviolet transmittance of 80%), and a model #20 RDS wire rod is used to coat the viscose layer with a thickness of 7um. Capable of glass film 1.

Embodiment 2

[0025] 1. Adhesive formula (Tinuvin477: Tinuvin400=1.8:1)

[0026]

[0027] 2. Preparation of glass film

[0028] Mix the components of the above formula uniformly and stir for 5-10 minutes to obtain a viscosity of 70-120cps

[0029] The visco-collagen solution is made of PET base film with a thickness of 23um (the base film itself has an ultraviolet transmittance of 80%), and a model #20 RDS wire rod is used to coat the viscose layer with a thickness of 8um. Capable of glass film 2.

Embodiment 3

[0031] 1. The formulation of the adhesive (Tinuvin477: Tinuvin400=1:1)

[0032]

[0033] 2. Preparation of glass film

[0034] Mix the components of the above formula uniformly and stir for 5-10 minutes to obtain a viscosity of 70-120cps

[0035] The visco-collagen solution is made of PET base film with a thickness of 23um (the base film itself has an ultraviolet transmittance of 80%), and a model #20 RDS wire rod is used to coat the viscose layer with a thickness of 8um. Capable of glass film 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com