White spirit aging accelerating agent, aging hastening method and aging tank

A technology for accelerating aging and liquor, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. The effect of simple process and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

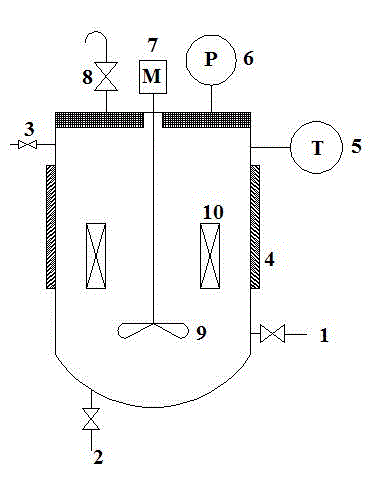

Method used

Image

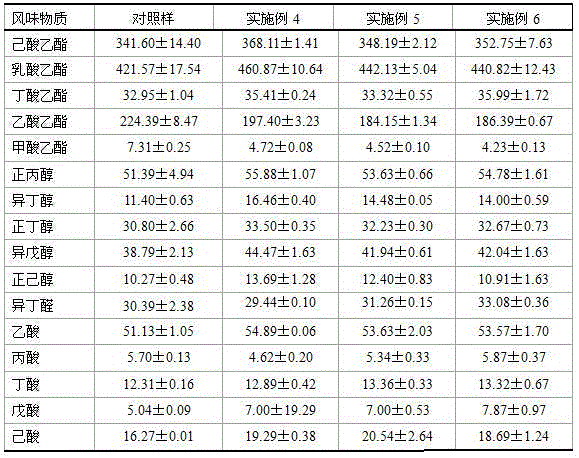

Examples

Embodiment 1

[0022] Embodiment 1: 10 g anhydrous FeCl 3 Add to 30 ml, 2 mol / L HCl solution, stir to dissolve, then add 8 g of urea, stir to obtain a clear liquid; add 30 g of attapulgite to 30 ml, 2 mol / L HCl solution, stir for 4 h; FeCl 3 - Mix urea solution with acid-treated attapulgite, stir for 2 hours, adjust the pH to 3.5 with 8% ammonia water; stir and crystallize for 18 hours, filter with suction, wash with water until there is no chloride ion, dry at 120°C, and calcined at 450°C After 6 h, a red fibrous attapulgite-based liquor aging aid was obtained.

Embodiment 2

[0023] Embodiment 2: with 10 g anhydrous FeCl 3 Add to 40 ml, 3 mol / L HCl solution, stir to dissolve, then add 10 g urea, stir to obtain a clear liquid; add 50 g attapulgite to 40 ml, 3 mol / L HCl solution, stir for 5 h; FeCl 3 - Mix urea solution with acid-treated attapulgite, stir for 3 hours; use 10% ammonia water to adjust pH to 4; stir and crystallize for 48 hours, filter with suction, wash with water until there is no chloride ion, dry at 125°C, and calcined at 500°C After 5 h, a red fibrous attapulgite-based liquor aging aid was obtained.

Embodiment 3

[0024] Embodiment 3: with 10 g anhydrous FeCl 3 Add 50 ml, 4 mol / L HCl solution, stir to dissolve, then add 12 g urea, stir to obtain a clear liquid; add 60 g of attapulgite to 50 ml, 4 mol / L HCl solution, stir for 6 h; FeCl 3 - Mix urea solution and acid-treated attapulgite, stir for 4 hours; adjust the pH to 5.0 with 12% ammonia water; stir and crystallize for 72 hours, filter with suction, wash with water until there are no chloride ions, dry at 130°C, and calcined at 550°C After 4 h, a red fibrous attapulgite-based liquor aging aid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com