A method for increasing the content of docosahexaenoic acid in Schizochytrium oil

A docosahexaenoic acid and Schizochytrium technology, applied in the field of microbial fermentation, can solve the problems of reducing fermentation costs and increasing production efficiency, and achieve the effects of improving quality, increasing DHA content, and promoting a large amount of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

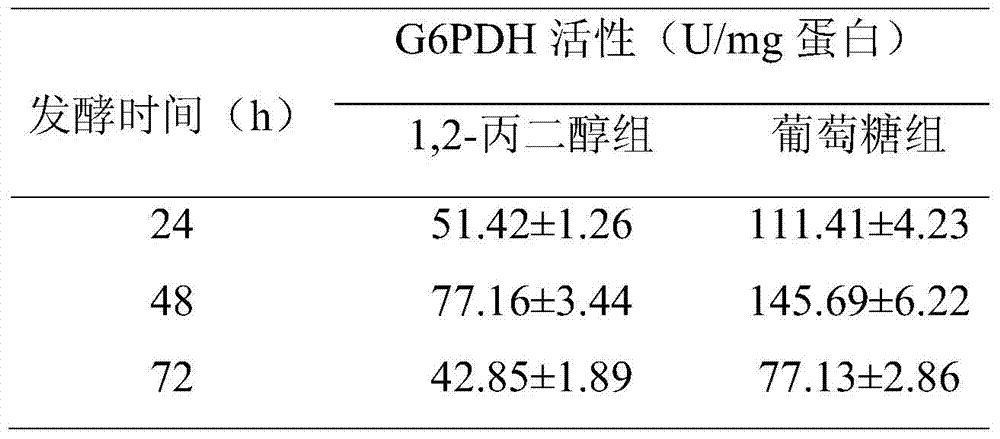

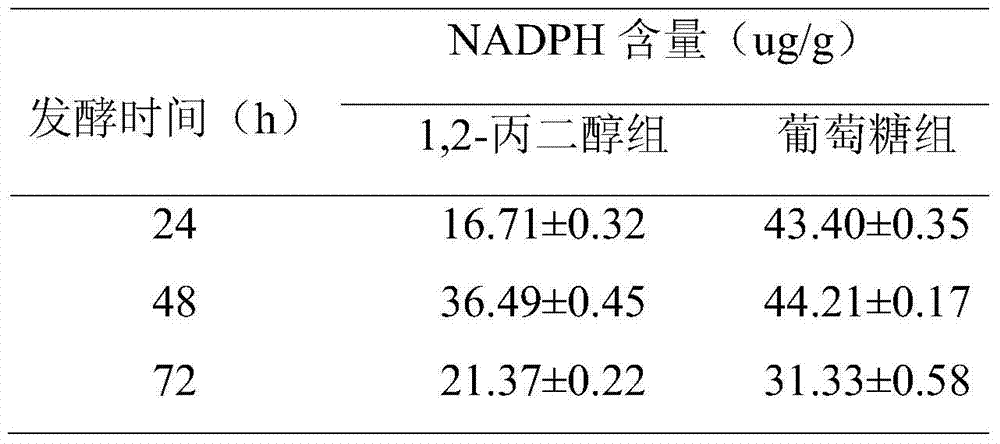

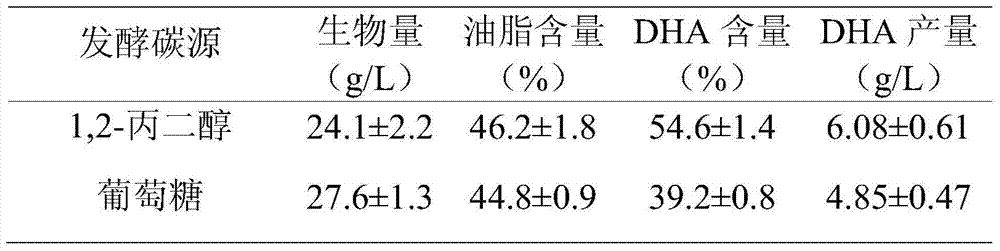

Examples

Embodiment 1

[0027] (1) Add 50 mL of seed medium to a 250 mL Erlenmeyer flask. Insert the cryopreserved Schizochytrium strains, culture them for 2 days at a culture temperature of 25°C and a shaker rotation speed of 200rpm, and activate the cryopreserved Schizochytrium strains into Schizochytrium seed liquid;

[0028] Seed medium components (g / L): glucose 15.0, yeast powder 6.0, beef extract 3.0, peptone 2.0, corn steep liquor 4.0, MgSO 4 ·7H 2 O 0.2, KH 2 PO 4 2.0, Sea Crystal 15.0.

[0029] (2) Add 50 mL of fermentation medium to a 250 mL Erlenmeyer flask, insert Schizochytrium into the fermentation medium with an inoculum size of 10%, and culture at a constant temperature of 26° C. for 3 days, with a rotation speed of 200 rpm;

[0030] Fermentation medium components (g / L): 1,2-propanediol 40.0, yeast extract 6.0, MgSO 4 ·7H 2 O 0.6, KH 2 PO 4 0.5, NaNO 3 1.0, Na 2 SO 4 5.0;

[0031] CK (g / L): glucose 40.0, yeast extract 6.0, MgSO 4 ·7H 2 O 0.6, KH 2 PO 4 0.5, NaNO ...

Embodiment 2

[0044] (1) Add 50 mL of seed medium to a 250 mL Erlenmeyer flask. Insert the cryopreserved Schizochytrium strains, culture them for 2 days at a culture temperature of 25°C and a shaker rotation speed of 200rpm, and activate the cryopreserved Schizochytrium strains into Schizochytrium seed liquid;

[0045] Seed medium components (g / L): glucose 25.0, yeast powder 8.0, peptone 5.0, corn steep liquor 2.0, MgSO 4 ·7H 2 O 0.6, KH 2 PO 4 1.5, sea crystal 10.0.

[0046] (2) Add 50 mL of fermentation medium to a 250 mL Erlenmeyer flask, insert Schizochytrium into the fermentation medium with an inoculum size of 8%, and culture at a constant temperature of 26° C. for 3 days at a speed of 200 rpm;

[0047] Fermentation medium components (g / L): 1,2-propanediol 50.0, yeast extract 10.0, sodium glutamate 5.0, MgSO 4 ·7H 2 O 0.2, KH 2 PO 4 2.0, (NH 4 ) 2 SO 4 3.0, NaNO 3 2.0, Na 2 SO 4 8.0;

[0048] CK (g / L): glucose 50.0, yeast extract 10.0, sodium glutamate 5.0, MgSO 4...

Embodiment 3

[0057] (1) Add 50 mL of seed medium to a 250 mL Erlenmeyer flask. Insert the cryopreserved Schizochytrium strains, culture them for 2 days at a culture temperature of 25°C and a shaker rotation speed of 200rpm, and activate the cryopreserved Schizochytrium strains into Schizochytrium seed liquid;

[0058] Seed medium components (g / L): glucose 30.0, yeast powder 4.0, beef extract 5.0, corn steep liquor 6.0, MgSO 4 ·7H 2 O 1.0, KH 2 PO 4 0.5, sea crystal 20.0.

[0059] (2) Add 50 mL of fermentation medium to a 250 mL Erlenmeyer flask, insert Schizochytrium into the fermentation medium with an inoculum size of 4%, and culture at a constant temperature of 26° C. for 3 days, with a rotation speed of 200 rpm;

[0060] Fermentation medium components (g / L): 1,2-propanediol 60.0, yeast extract 15.0, sodium glutamate 10.0, MgSO 4 ·7H 2 O 1.0, KH 2 PO 4 1.5, (NH 4 ) 2 SO 4 5.0, NaNO 3 3.0, Na 2 SO 4 12.0;

[0061] After the fermentation medium was sterilized, the exog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com